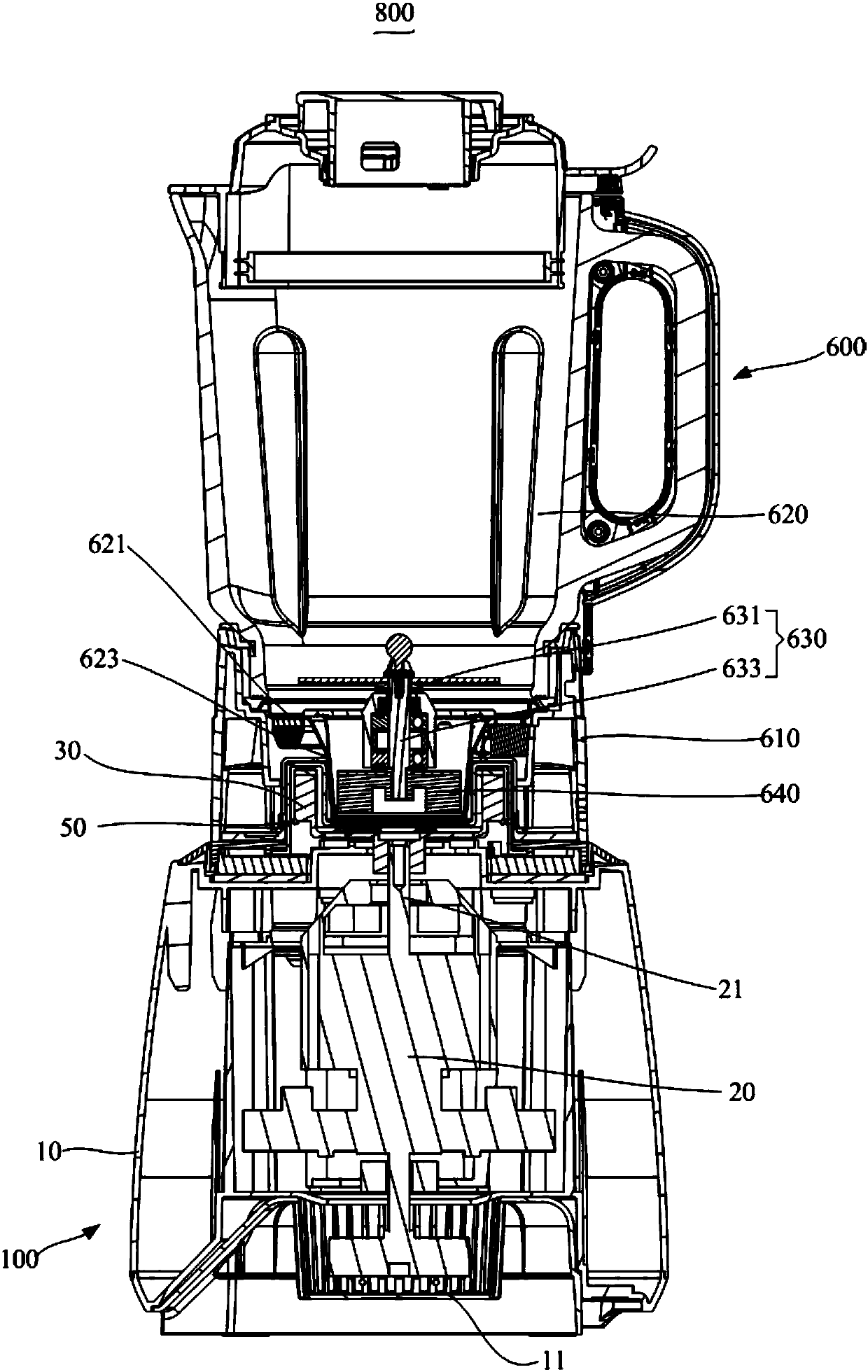

Base component and food processor

A food processing machine and component technology, applied in the field of food processing machines, can solve the problems of human safety impact, disk component damage, etc., and achieve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

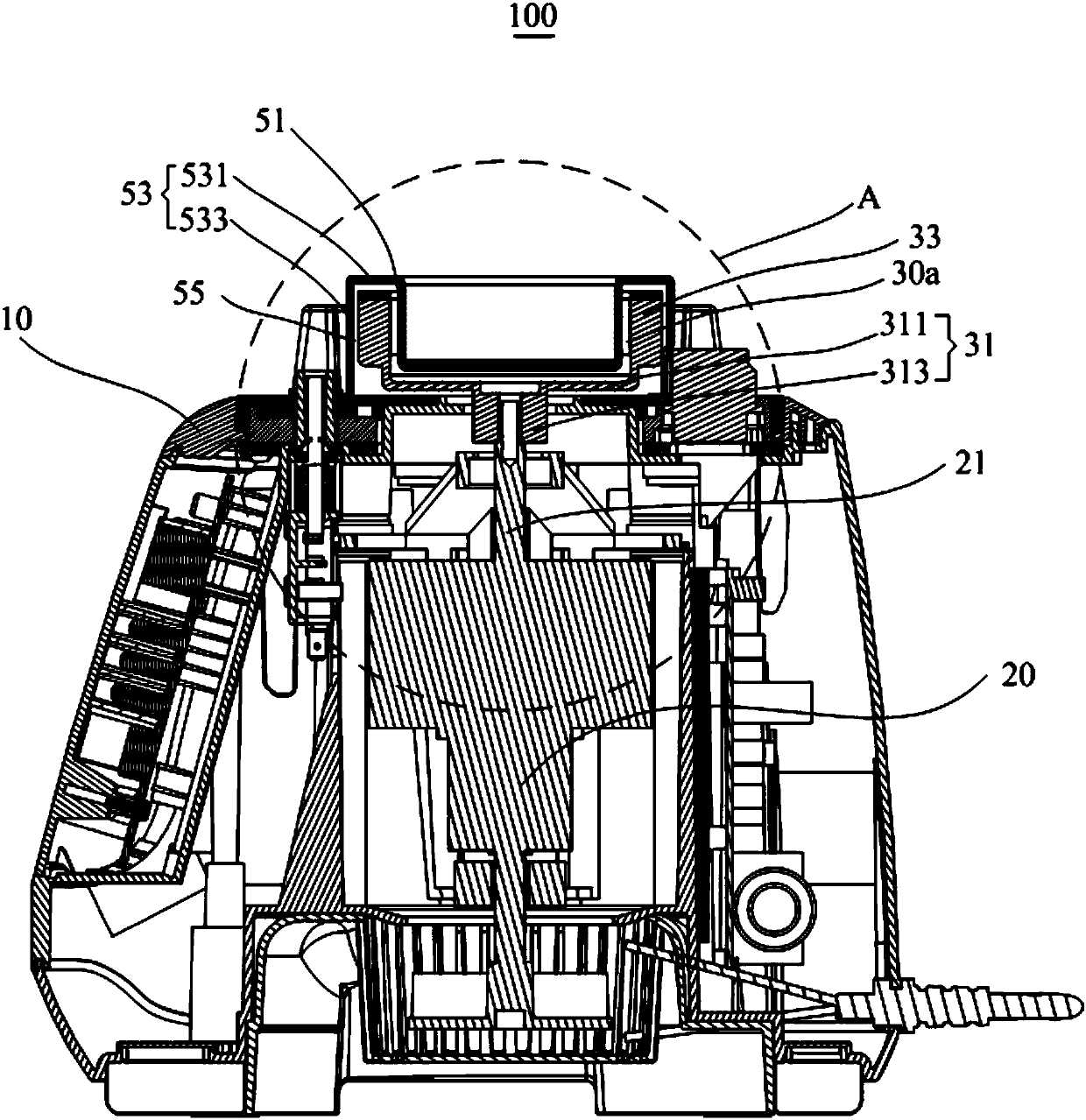

Embodiment 1

[0083] Embodiment 1: The heating device is a resistance heating assembly, which is arranged at the bottom of the stirring cup 620, and the resistance heating assembly includes a cup plate 621 connected to the lower end of the stirring cup 620 and a resistance set on the lower surface of the cup plate 621 Heating pipe. The cup plate 621 is generally a stainless steel plate. The resistance heating tube heats the cup and tray 621 , and the cup and tray 621 transmits heat to the stirring cup 620 . The resistance heating tube and the cup and plate 621 can be set as one or separately, and the way of setting between the two can be set according to specific conditions.

Embodiment 2

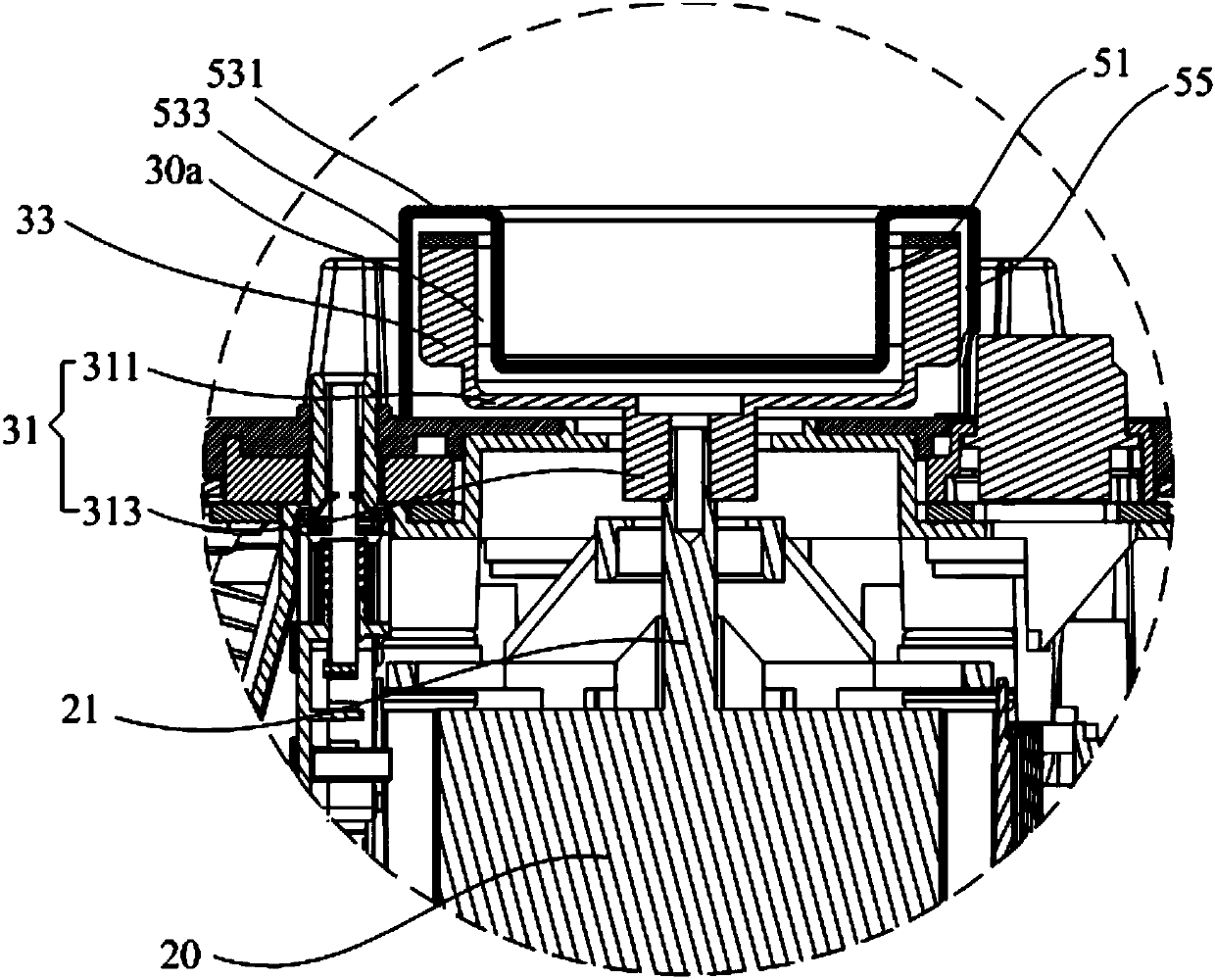

[0084] Embodiment 2: The heating device is an electromagnetic heating assembly, and the cup plate 621 is a conduction plate. The electromagnetic heating assembly is arranged at the lower end of the stirring cup 620. The electromagnetic heating assembly includes an electromagnetic coil plate arranged below the conduction plate.

[0085] The magnetically conductive disk is generally a magnetically conductive stainless steel disk that can be integrally made of magnetically conductive metal materials, such as 430 stainless steel or cast iron. Of course, the conductive disc can also be made of a disc body made of a non-magnetic material such as ceramics, and a magnetic permeable film attached to the bottom surface of the disc body. The electromagnetic heating disk assembly conducts electromagnetic heating on the conductive disk to heat the liquid in the stirring cup 620 .

[0086] The conductive disk is heated by means of electromagnetic heating, and the life of the electromagnetic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com