Platen superheater

A panel superheater and superheater technology, applied in steam superheating, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problem of low thermal conductivity, adhesion to the surface of the panel superheater, and reduce panel overheating The heat absorption effect of the device and other issues can be achieved to ensure normal heat absorption, low use cost, and change the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

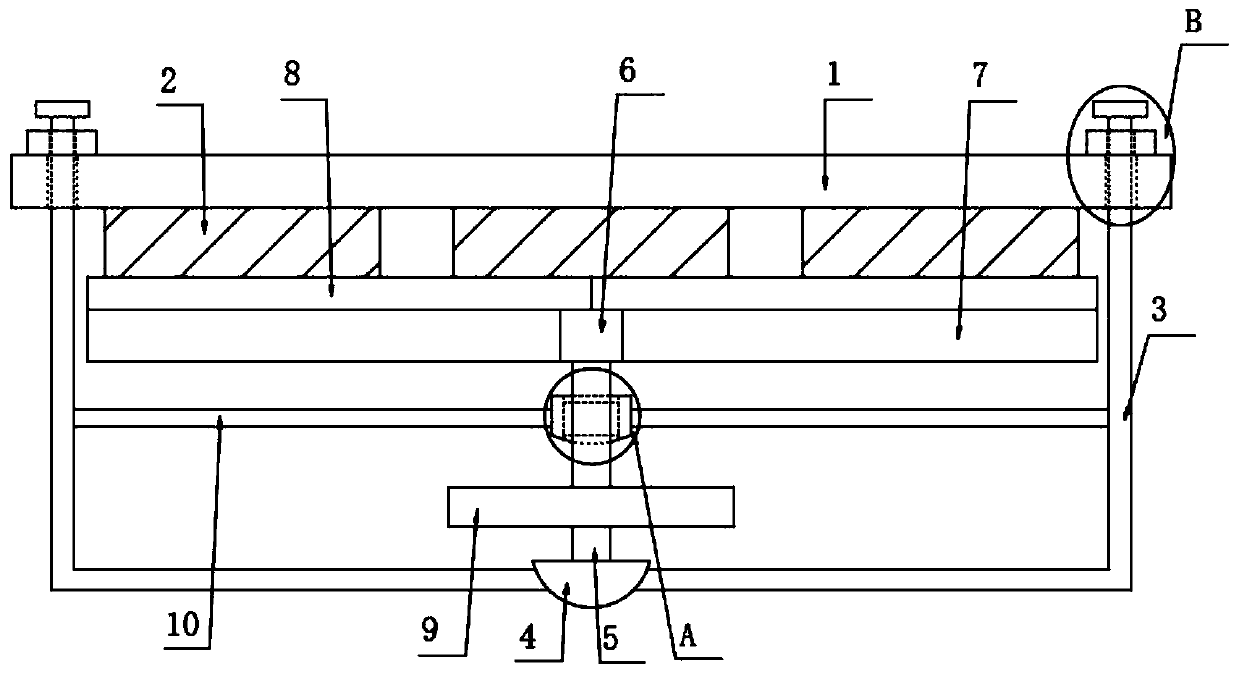

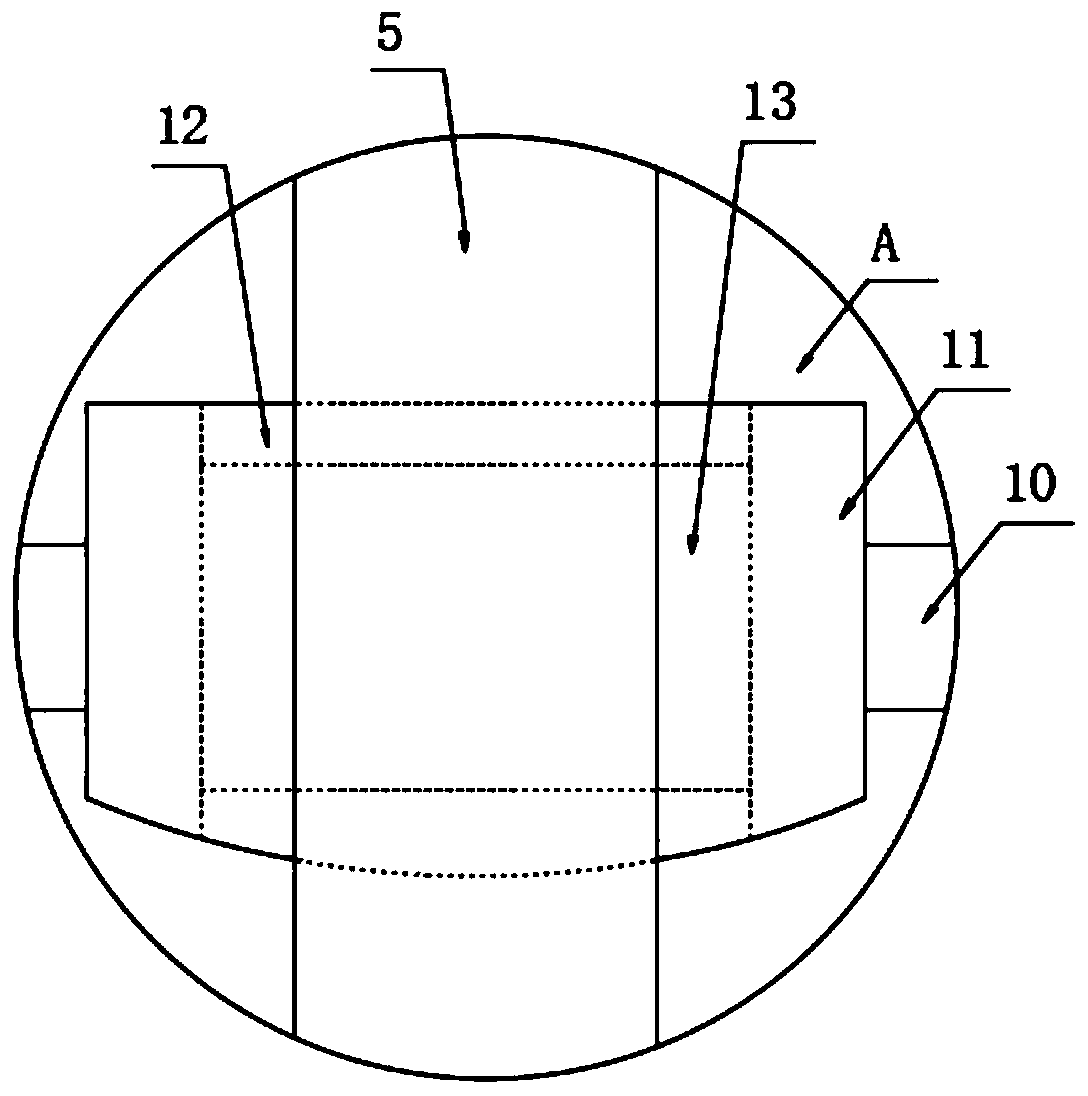

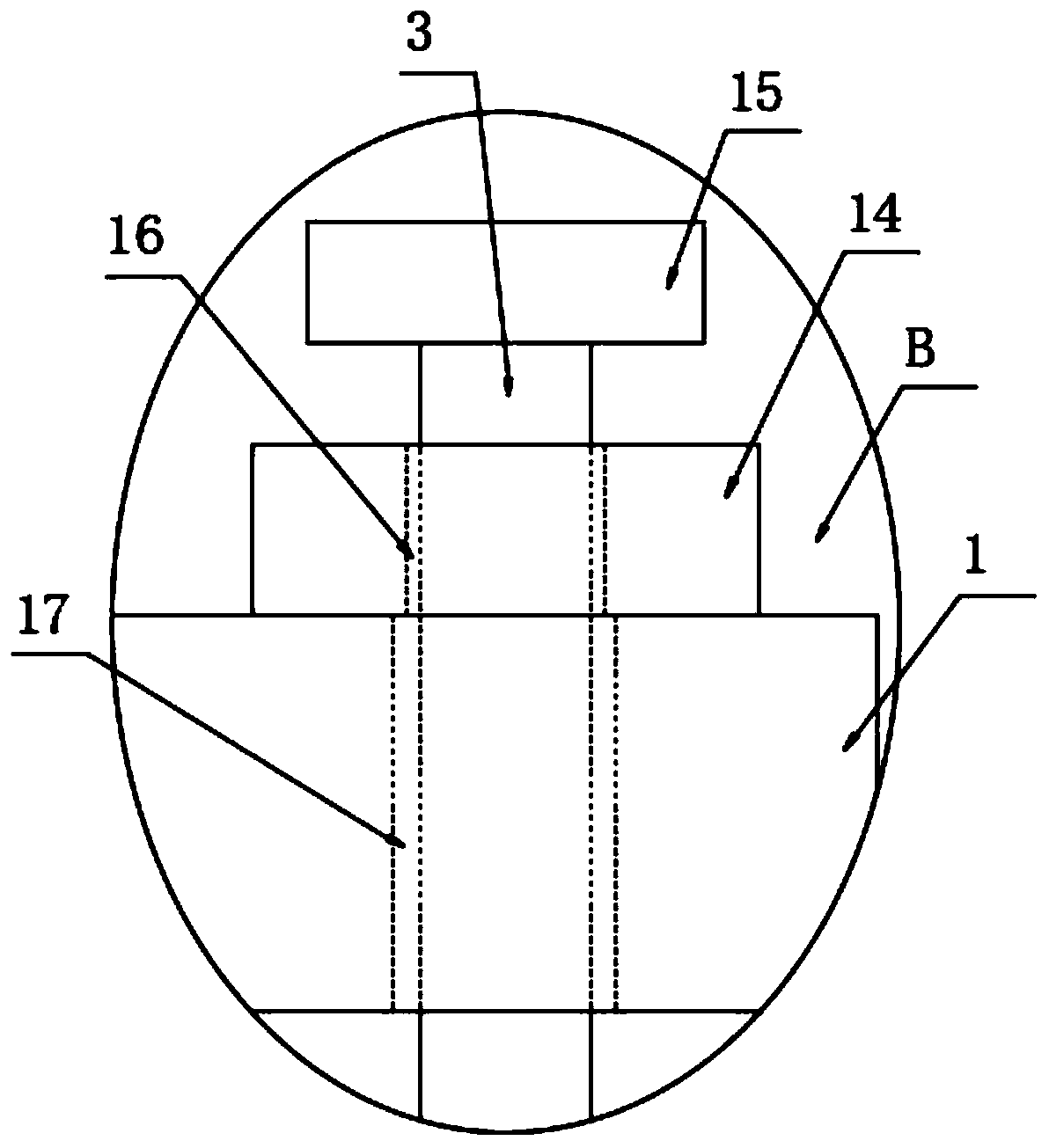

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0022] combine Figure 1-4 , a panel-type superheater, including a superheater 2 fixedly installed on a steel frame 1, two L-shaped fixed rods 3 are installed on the steel frame 1, and one end of the two L-shaped fixed rods 3 close to each other is fixed and installed together A fixed block 4, the rotating shaft 5 is fixedly installed on the fixed block 4, the mounting block 6 and the fan blade 9 are fixedly installed on the rotating shaft 5, and the fan blade 9 is made of the same material as the superheater 2.

[0023] Two rods 7 are fixedly installed on the side of the mounting block 6, and a high-temperature-resistant rubber 8 is fixed on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com