Anti-overheating film for solar thermal collector

A solar collector and thermal film technology, which is used in solar thermal power generation, solar thermal devices, coatings, etc., can solve problems such as the inability to solve the harm of the collector, prevent the collector from overheating, control the air temperature, The effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

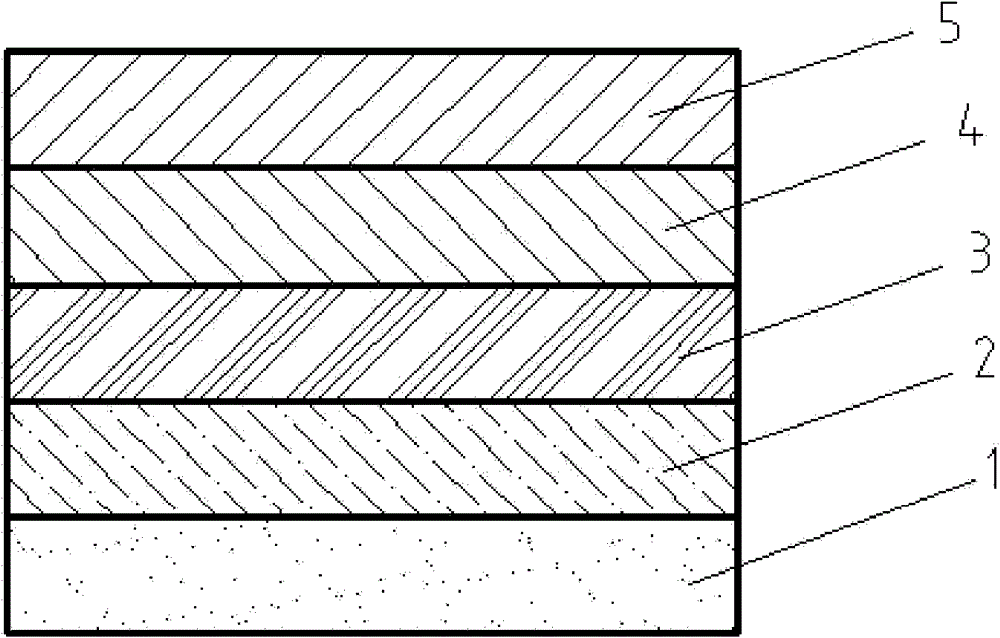

[0027] see figure 1 , the film layer described in the embodiment of the utility model is used for vacuum heat collectors, and the preparation method adopts common magnetron sputtering technology. In this example, the second bottom metal layer 3 selects aluminum with a thickness of 80 nanometers, and the second bottom metal layer 3 is stainless steel with a thickness of 10 nanometers. The absorption layer 4 and the anti-reflection layer 5 adopt an interference absorption film layer. The total thickness of the absorption layer 4 and the anti-reflection layer 5 is about 220 nanometers. Gas, the absorption ratio of the film layer can reach 0.943, and the normal emission ratio is 0.065. At an irradiance of 800W / m 2 , the drying temperature of the vacuum tube can reach 270 ℃.

example 2

[0029] see figure 1 , in this example, the second bottom metal layer 3 is selected from aluminum with a thickness of 80 nanometers, the second bottom metal layer 3 is stainless steel with a thickness of 100 nanometers, the absorption layer 4 and the anti-reflection layer 5 adopt an interference absorption film layer, and the absorption layer 4 and the total thickness of the anti-reflection layer 5 is about 220 nanometers. After vacuum baking and exhausting at 450°C, the absorption ratio of the film layer can reach 0.945, the normal emission ratio is 0.129, and the irradiance is 800W / m 2 , the drying temperature of the vacuum tube is 190°C.

example 3

[0031] see figure 1 , in this example, the second bottom metal layer 3 is selected from aluminum with a thickness of 80 nanometers, the second bottom metal layer 3 is stainless steel with a thickness of 150 nanometers, the absorption layer 4 and the anti-reflection layer 5 adopt interference absorption film layers, and the absorption layer 4 And the total thickness of the anti-reflection layer 5 is about 220 nanometers. After vacuum baking and exhausting at 450°C, the absorption ratio of the film layer can reach 0.944, the normal emission ratio is 0.165, and the irradiance is 800W / m 2 , the drying temperature of the vacuum tube is 160°C.

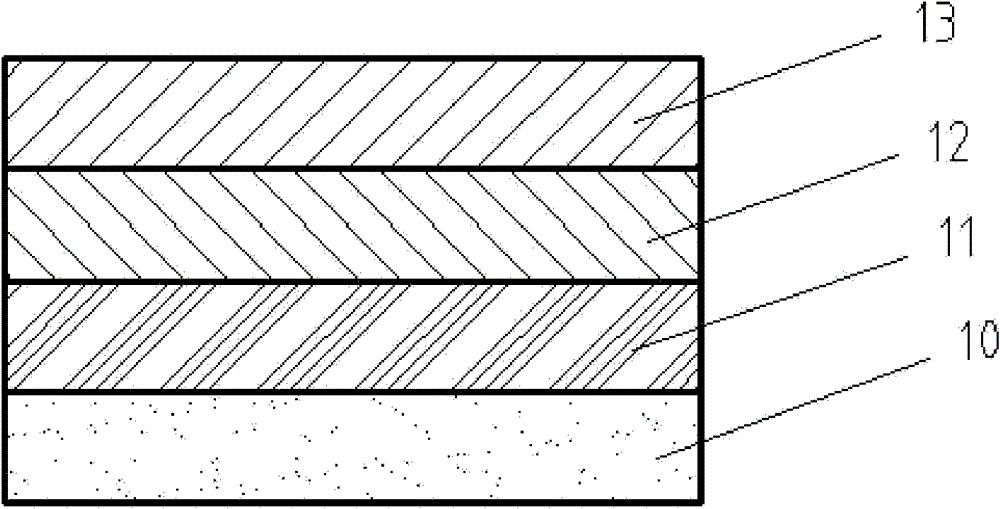

[0032] The utility model also provides another anti-overheating film layer for solar heat collectors, comprising a bottom metal layer 11, an absorbing layer 12 and an anti-reflection layer 13 which are sequentially arranged on the substrate 10, and the bottom metal layer 11 is composed of Combination of two metals with different emissivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com