A kind of elastic net cloth and its production method

A production method and elastic technology, applied in the direction of yarn, one-component polyester rayon, textiles and papermaking, etc., can solve the problems of inability to stretch freely, poor fabric elasticity, poor comfort, etc., to reduce danger and prevent warping , the effect of excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A production method of elastic mesh cloth, the specific steps are:

[0043] 1. Preparation of spandex coated polyester yarn

[0044] Using spandex and modified polyester fibers as raw materials, a spandex-coated polyester yarn is prepared through a blending process, wherein the mass fraction of spandex in the spandex-coated polyester yarn is 3%;

[0045] The main process of the spandex covering polyester yarn is: using DuPont 20~70D "Lycra" spandex as the inner covering yarn, and using 80D / 24f modified polyester fiber as the outer covering yarn to control overfeeding during covering The rate is 5%~10%;

[0046] 2. Preparation of elastic mesh

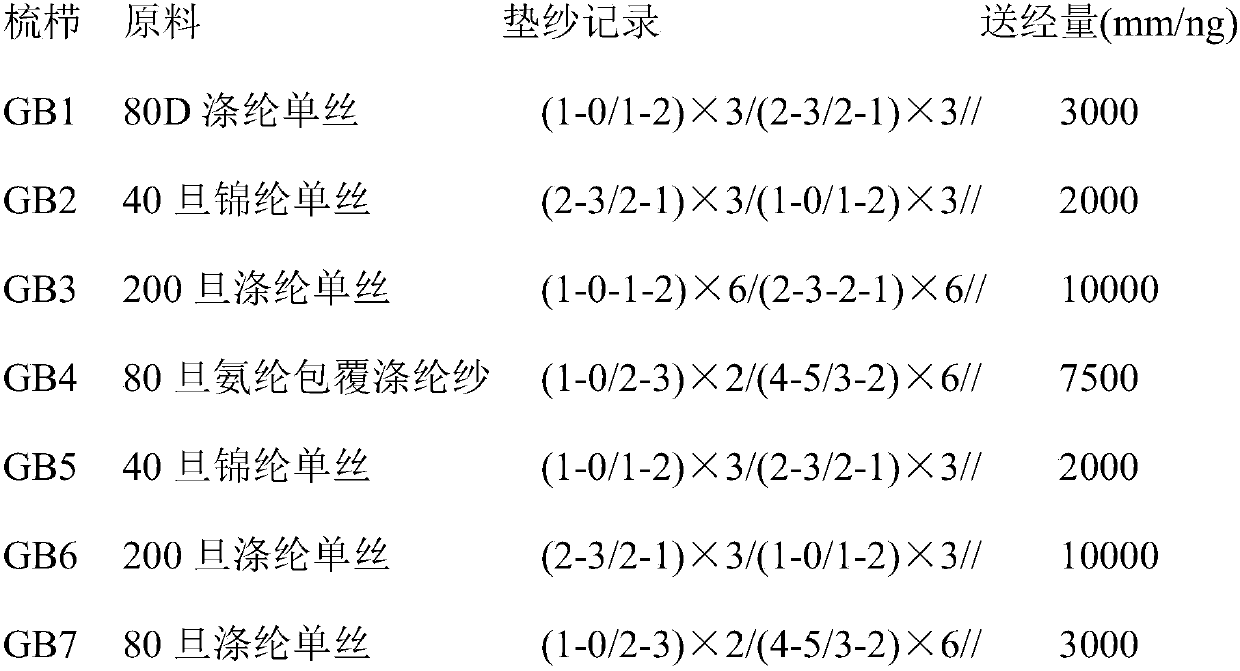

[0047] Using conventional polyester monofilament, polyamide monofilament, and spandex coated polyester yarn as raw materials, the three-dimensional mesh warp knitting method is used for warp knitting, warping warping, warp knitting, and finishing. Elastic mesh

[0048] The conventional polyester monofilament is 40-400D polyester monofilame...

Embodiment 2

[0070] A production method of elastic mesh cloth, the specific steps are:

[0071] 1. Preparation of spandex coated polyester yarn

[0072] Using spandex and modified polyester fibers as raw materials, a spandex-coated polyester yarn is prepared through a blending process, wherein the mass fraction of spandex in the spandex-coated polyester yarn is 6%;

[0073] The main process of the spandex covering polyester yarn is: using DuPont 20~70D "Lycra" spandex as the inner covering yarn, and using 80D / 24f modified polyester fiber as the outer covering yarn to control overfeeding during covering The rate is 5%~10%;

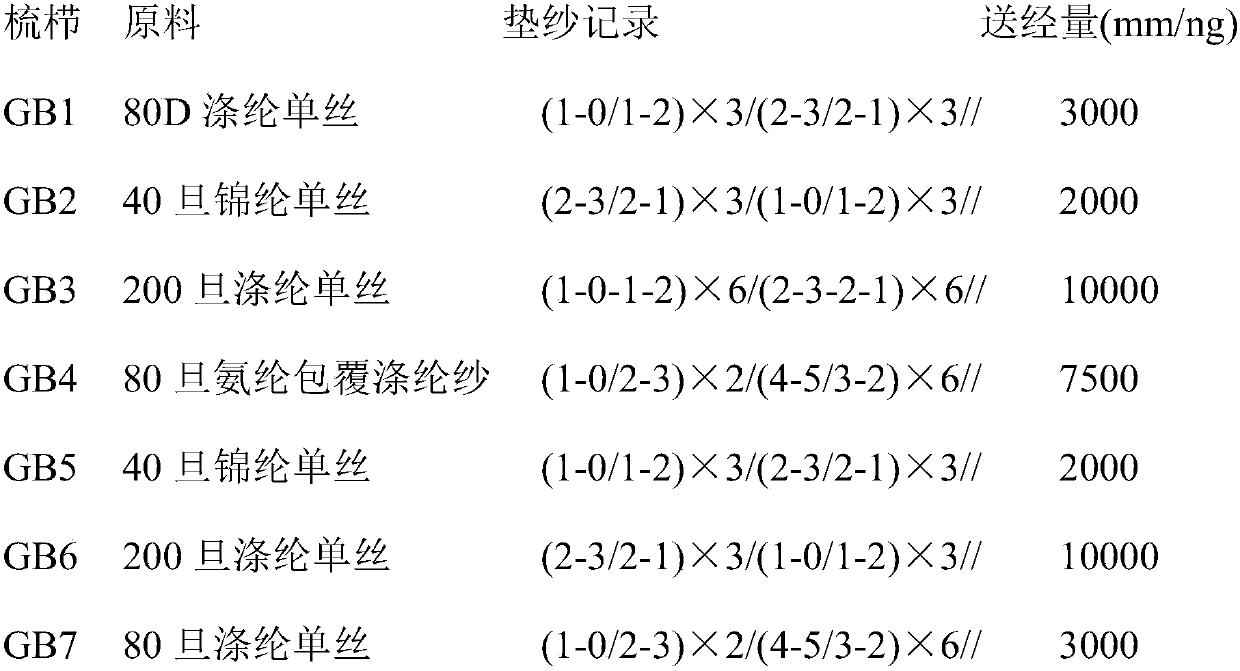

[0074] 2. Preparation of elastic mesh

[0075] Using conventional polyester monofilament, polyamide monofilament, and spandex coated polyester yarn as raw materials, the three-dimensional mesh warp knitting method is used for warp knitting, warping warping, warp knitting, and finishing. Elastic mesh

[0076] The conventional polyester monofilament is 40-400D polyester monofilame...

Embodiment 3

[0097] A production method of elastic mesh cloth, the specific steps are:

[0098] 1. Preparation of spandex coated polyester yarn

[0099] Using spandex and modified polyester fibers as raw materials, a spandex-coated polyester yarn is prepared through a blending process, wherein the mass fraction of spandex in the spandex-coated polyester yarn is 10%;

[0100] The main process of the spandex covering polyester yarn is: using DuPont 20~70D "Lycra" spandex as the inner covering yarn, and using 80D / 24f modified polyester fiber as the outer covering yarn to control overfeeding during covering The rate is 5%~10%;

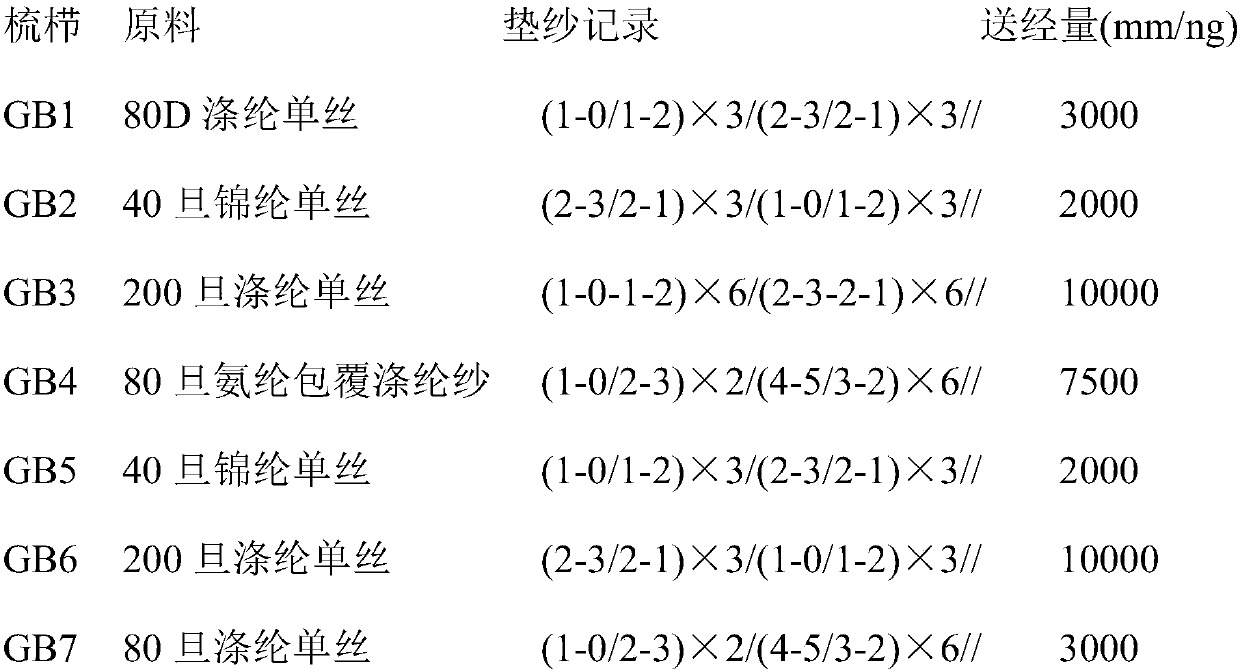

[0101] 2. Preparation of elastic mesh

[0102] Using conventional polyester monofilament, polyamide monofilament, and spandex coated polyester yarn as raw materials, the three-dimensional mesh warp knitting method is used for warp knitting, warping warping, warp knitting, and finishing. Elastic mesh

[0103] The conventional polyester monofilament is 40-400D polyester monofilam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com