Intelligent biomass furnace with automatic temperature adjustment

A biomass furnace, automatic technology, applied in the direction of solid fuel combustion, indirect carbon dioxide emission reduction, non-flammable liquid/gas transportation, etc., can solve problems such as extinguishing, fuel cannot be fully burned, and dye burning speed slows down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

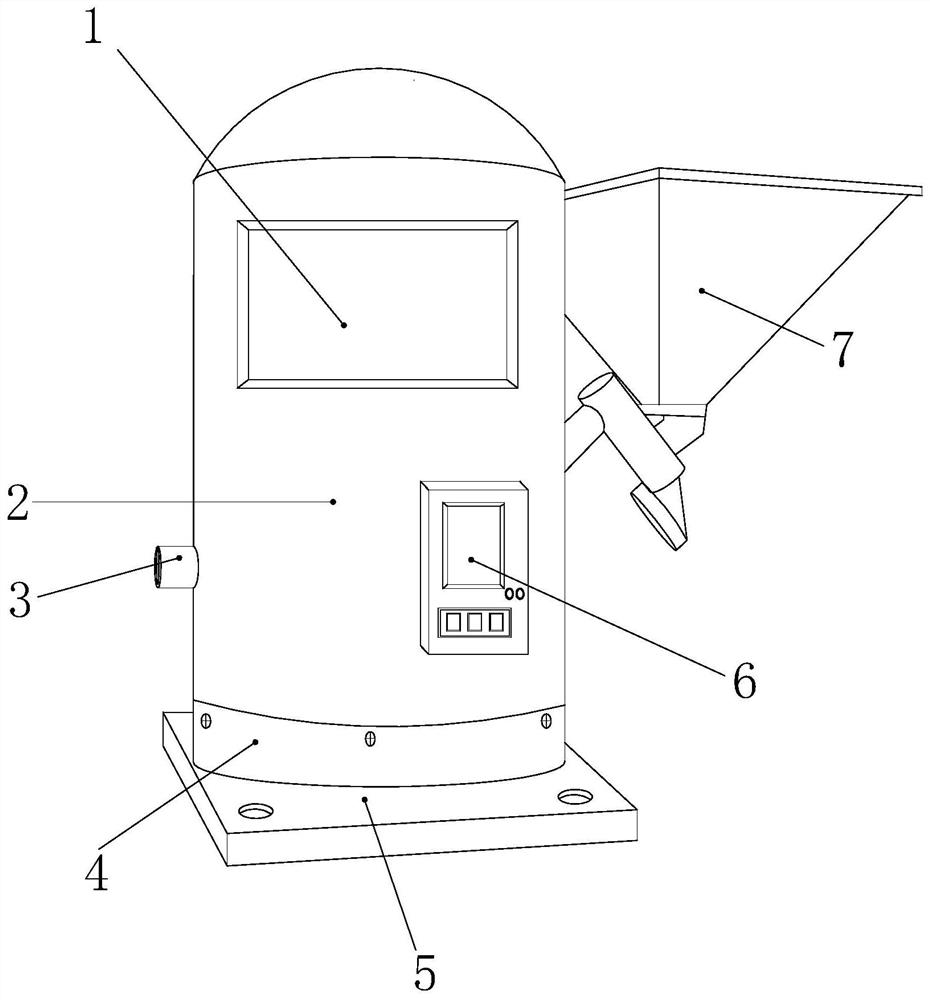

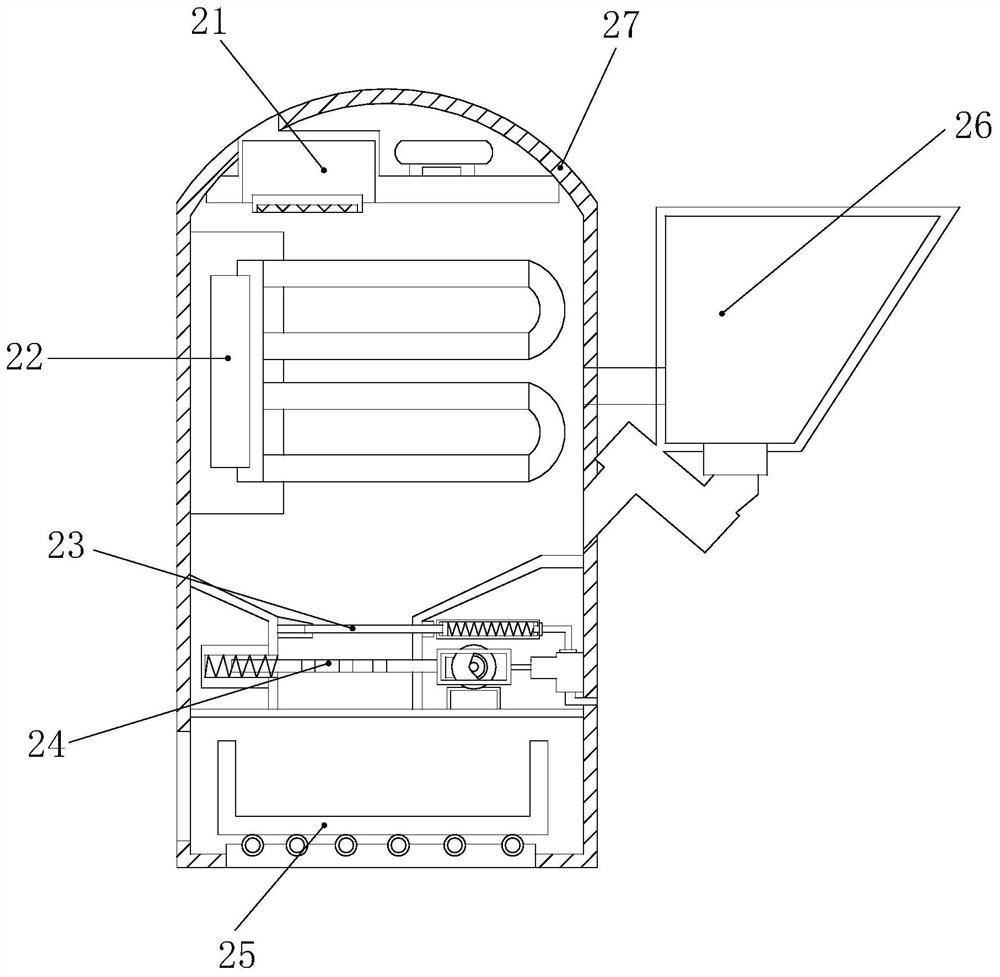

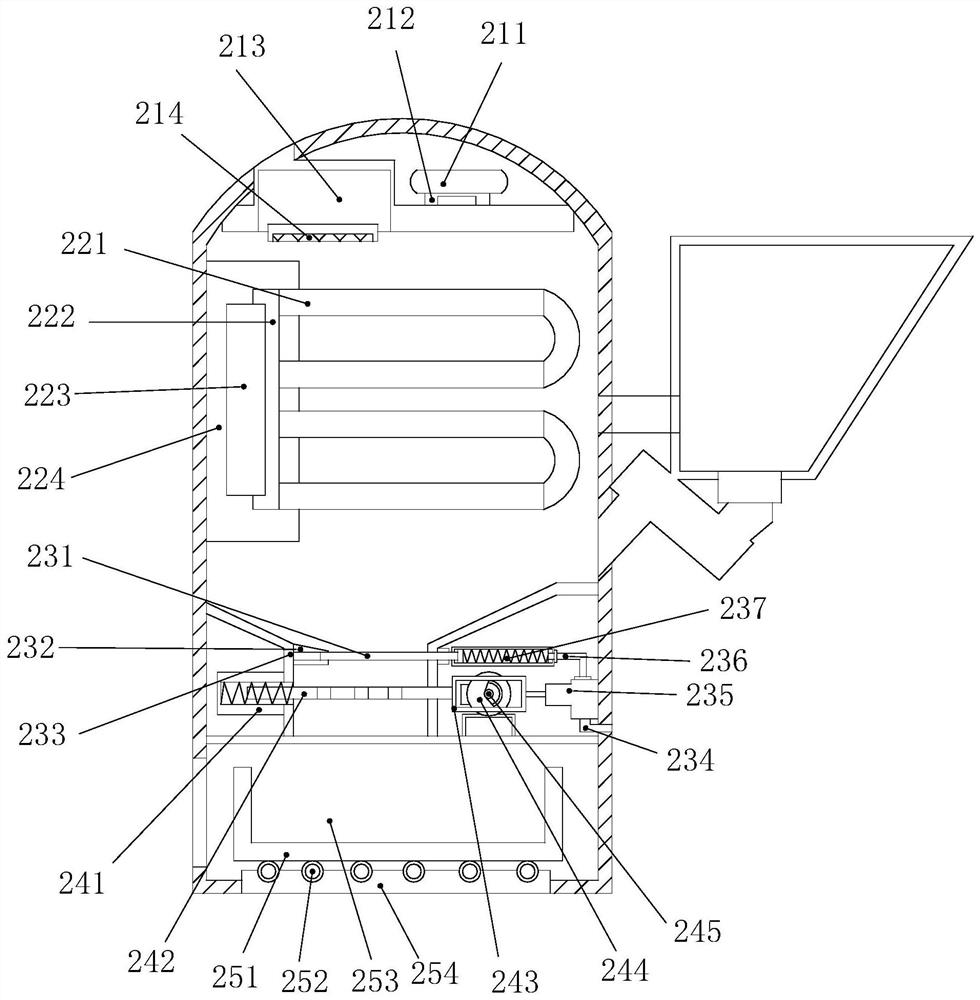

[0024] see Figure 1-Figure 6, the present invention provides an intelligent biomass furnace with automatic temperature regulation. 1 is arranged on the furnace body 2, and the two are welded together, the fire outlet 3 is arranged at the left end of the furnace body 2, and the two are integrated structures, the connecting ring 4 is arranged at the bottom end of the furnace body 2, and The two are integrated structures, the thermostat 6 is arranged at the front end of the furnace body 2, and the two are welded together, the left end of the feed inlet 7 is welded to the right end of the furnace body 2, and the furnace body 2 includes a row Smoke structure 21, heating mechanism 22, baffle mechanism 23, vibrating mechanism 24, material storage mechanism 25, feeding mechanism 26, and shell 27. The smoke exhaust structure 21 is arranged on the top of the shell 27, and the two are welded together. The heating mechanism 22 is located directly below the smoke exhaust structure 21, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap