Device and method for quantitatively simulating seam width dynamic change during temporary blocking in seam

A technology of dynamic change and slit width, applied in the direction of measuring devices, using stable tension/pressure test material strength, instruments, etc., can solve the problems of inability to simulate crack surface morphology and dynamic slit width changes, etc., to achieve quantification Effects of simulation and real-time monitoring of fracture width dynamic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

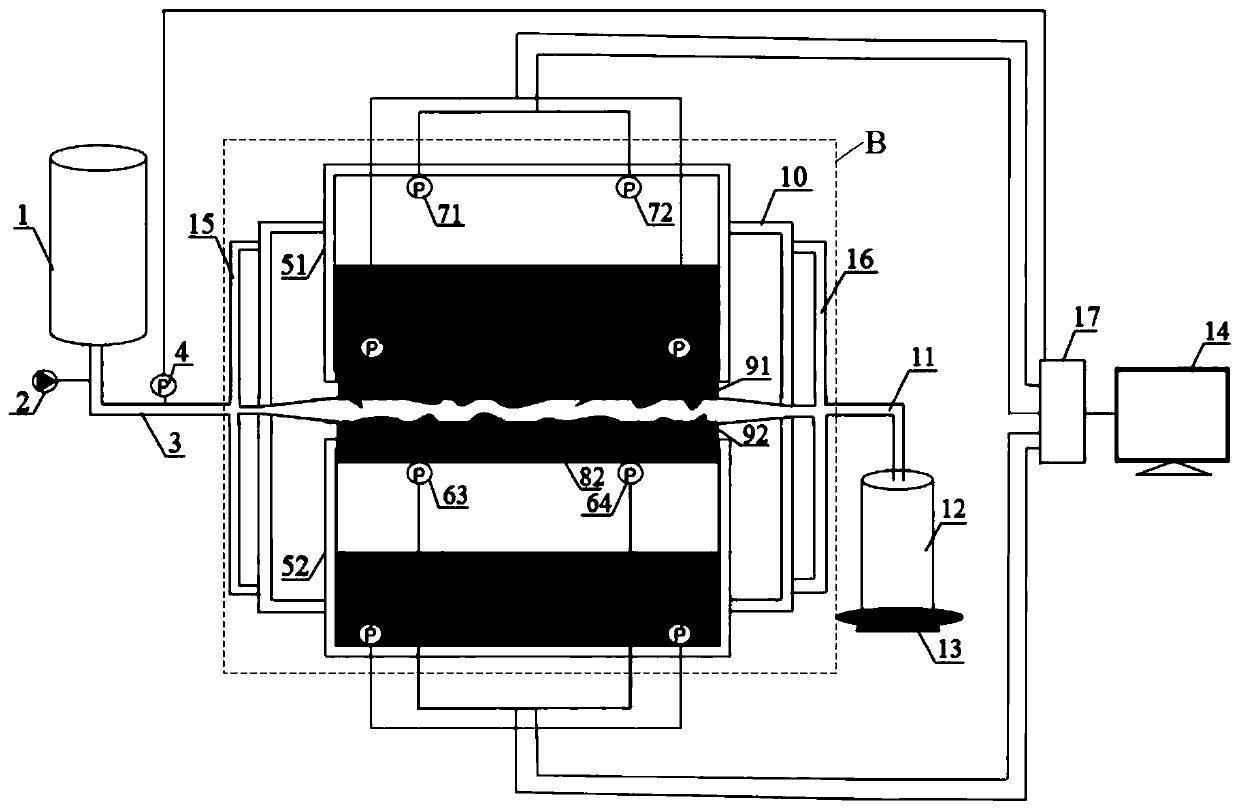

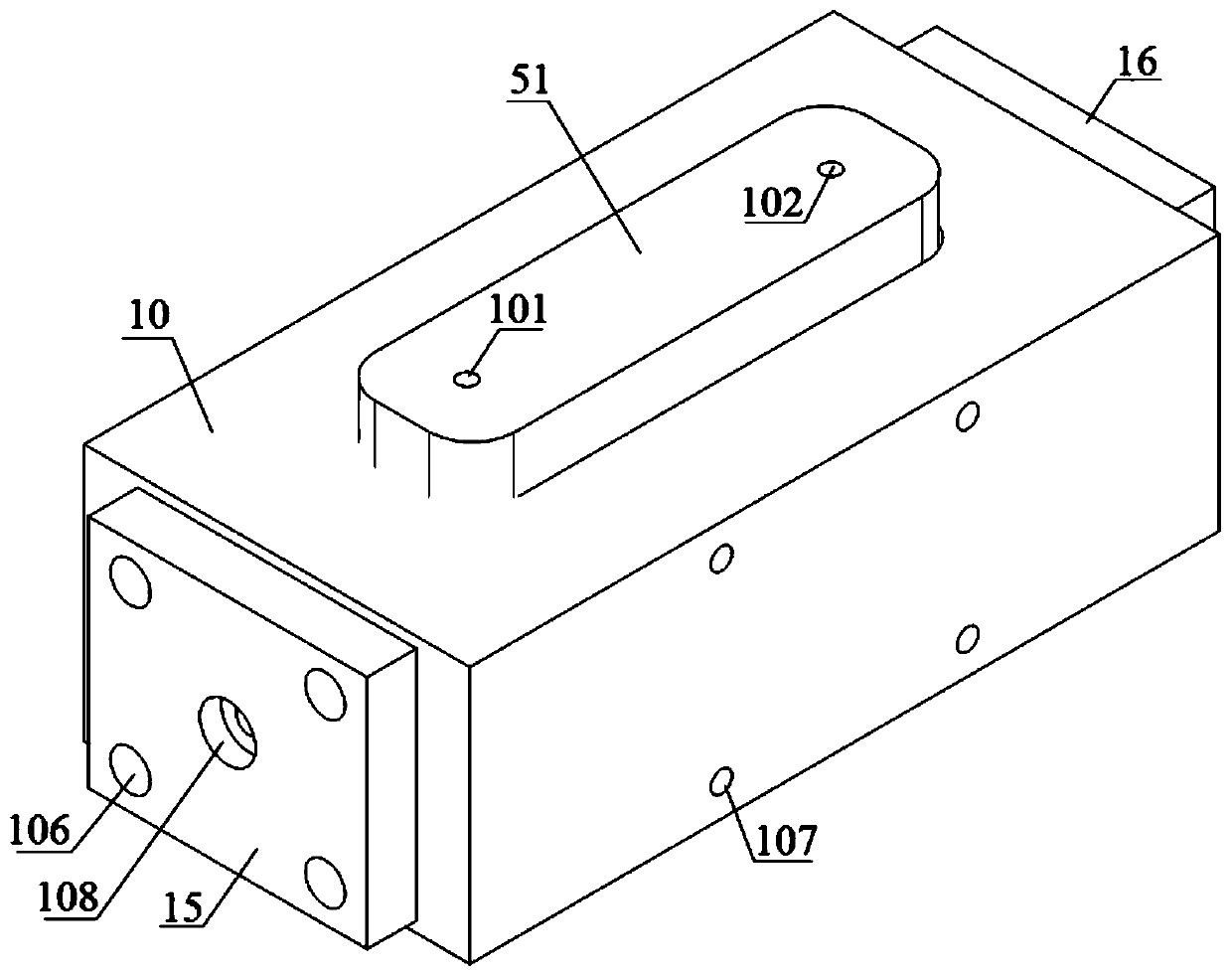

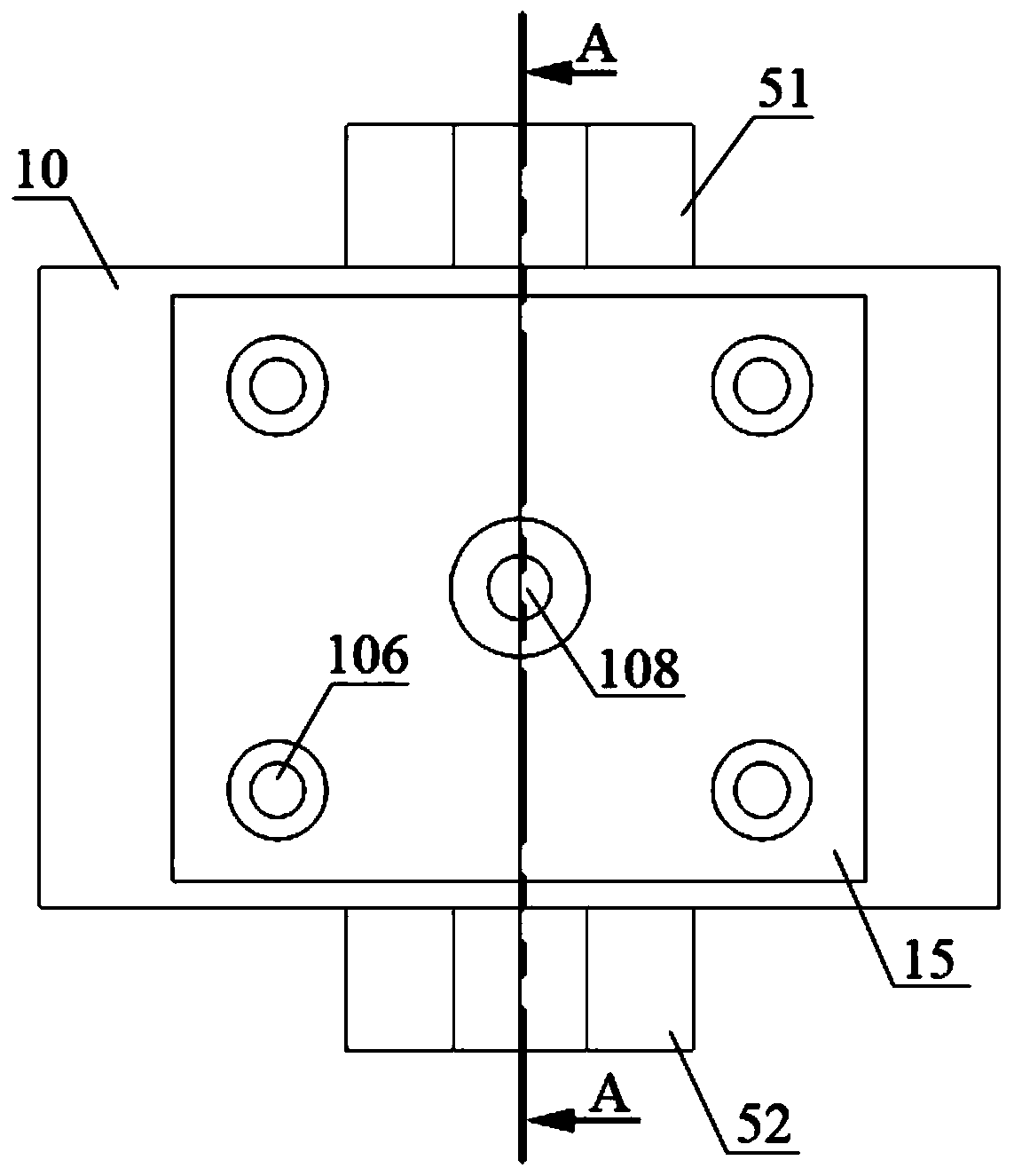

[0074] This embodiment provides a device for quantitatively simulating the dynamic change of the fracture width when the fracture is temporarily blocked, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the device includes:

[0075] The first chamber 51, the second chamber 52, the first piston 81, the second piston 82, the first 3D printing fracture surface 91, the second 3D printing fracture surface 92, the monitoring and processing system, the liquid injection system and the liquid collection system;

[0076] The inner surface of the first piston 81 is used to seal the first chamber 51, and the first piston 81 can perform piston movement in the first chamber 51; the inner surface of the second piston 82 is used to seal the second chamber 52, And the second piston 82 can perform piston movement in the second chamber 52; the first chamber 51 and the second chamber 52 are used to load the mixed phase;

[0077] One side of the first 3D printed crack surface 91...

Embodiment 2

[0091] This embodiment provides a method for quantitatively simulating the dynamic change of the fracture width when the fracture is temporarily blocked, and the method includes the following steps:

[0092] Step 1, according to the Young's modulus E of the target layer rock f , horizontal stress difference σ H -σ h , the pressure in the seam P inj and seam height H f Calculation of fracture width w under formation conditions f ;Calculated as follows:

[0093] f(w f ) = f(σ H -σ h ,E f , H f , P inj );

[0094] Among them, σ H is the maximum horizontal stress of the target layer, σ h is the minimum horizontal stress of the target layer;

[0095] In this implementation, temporary plugging and diversion fracturing is carried out for layer F of well A in an oilfield in the west, in-situ stress and rock mechanics parameters are obtained through well logging interpretation, and the formation pressure of layer F is obtained through well test data. The following is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com