Fabric fuzzy ball grade evaluation method based on relative total variation model and MSER

A technology of relative total variation and grade evaluation, applied in the field of grade evaluation, can solve problems such as uneven illumination, influence of texture information, inability to accurately segment hair balls, etc., to enhance hair ball information, eliminate uneven lighting, objective and accurate The effect of evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

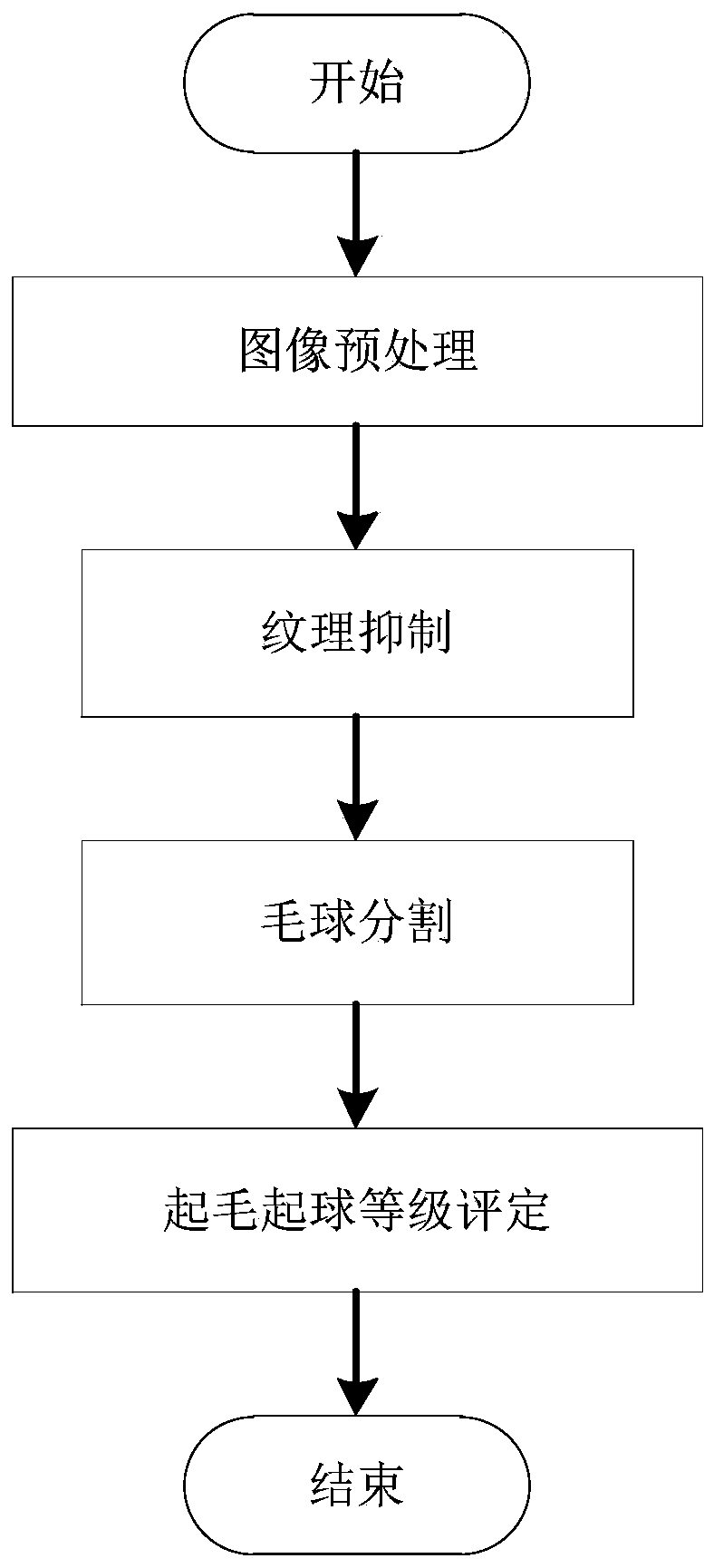

[0115] Use this method to take photos of standard samples, such as figure 2 Shown are 1-5 fabric pompom images for analysis. The computer processor used in the experiment is Intel i5-4460, the main frequency is 3.20GHz, equipped with 4G memory, Windows 7 operating system, and the software compilation environment is MatlabR2015b.

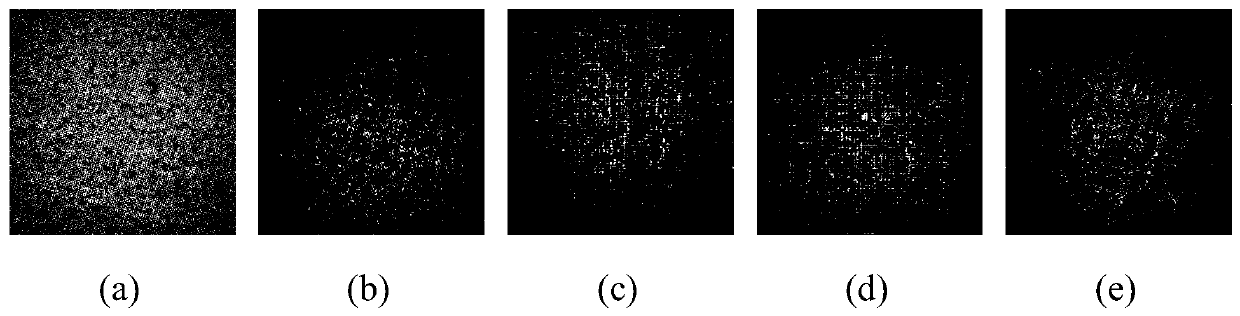

[0116] After preprocessing in step 1, the images are as follows: image 3 and Figure 4 shown, from figure 2 and image 3 Contrast results: After processing the hair ball image through histogram equalization, the contrast between the hair ball and the fabric texture background is enhanced. At the same time, it can be clearly seen that the periphery of the image is darker than the center of the image. This phenomenon occurs because the complex lighting conditions at the image collection site cause uneven illumination on the surface of the fabric, which is not conducive to the subsequent hairball segmentation. Therefore, it is necessary to elimina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com