Vertical cultivation frame and working method thereof

A cultivation rack and vertical technology, applied in cultivation, container cultivation, horticultural methods, etc., can solve the problems of poor plant management and picking, large space occupied by cultivation racks, affecting light efficiency, etc., so as to avoid uneven illumination and facilitate the Management or picking, the effect of favoring plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

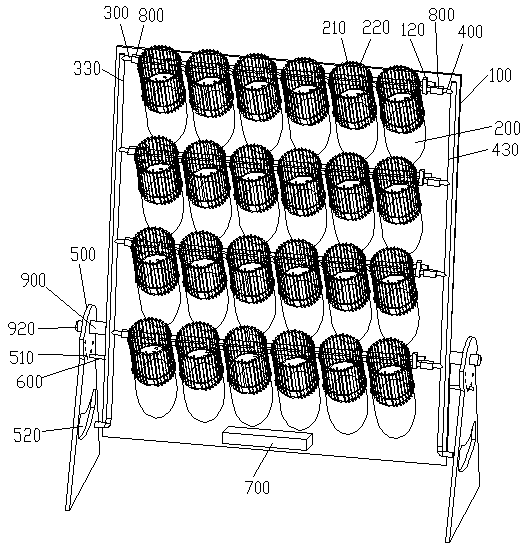

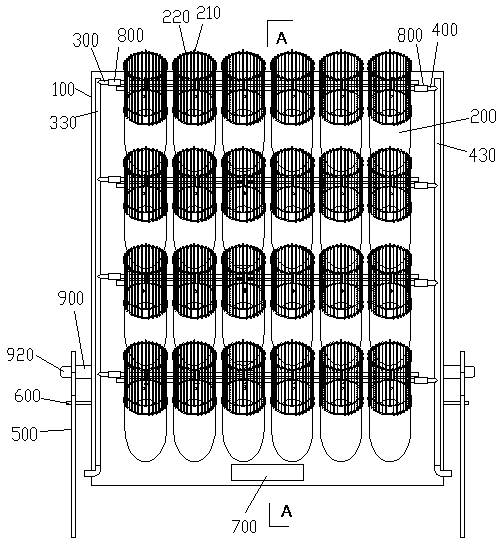

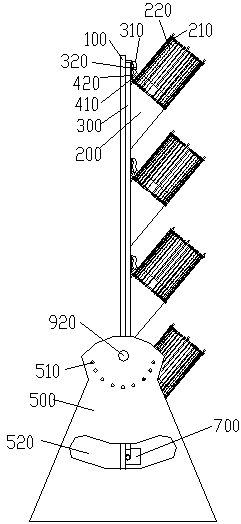

[0041] Such as Figure 1~14 Shown, a kind of vertical cultivation rack, comprises installation board 100, is provided with the cultivation pot 200 that several row openings are inclined upwards on installation board 100, is provided with colonization frame 210 on the upper opening of cultivation pot 200, on the colonization frame 210 LED plant growth lamps 220 are arranged on the top, water supply pipes 300 and nutrient solution pipes 400 are arranged above each row of cultivation pots 200, mounting frames 500 are hingedly arranged on both sides of the mounting plate 100, and several A limit hole 510, in the limit hole 510, a positioning pin shaft 600 that can move axially relative to the limit hole 510 is perforated, and a mounting hole 110 that is matched with the positioning pin shaft 600 is provided on the side of the mounting plate 100. A controller 700 for controlling the LED plant growth lamp 220 is disposed on the board 100 . The installation plate 100 adopts a transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com