A low-temperature three-way catalytic functional filter material and preparation method thereof

A filter material and low-temperature technology, applied in the field of low-temperature three-way catalytic functional filter material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

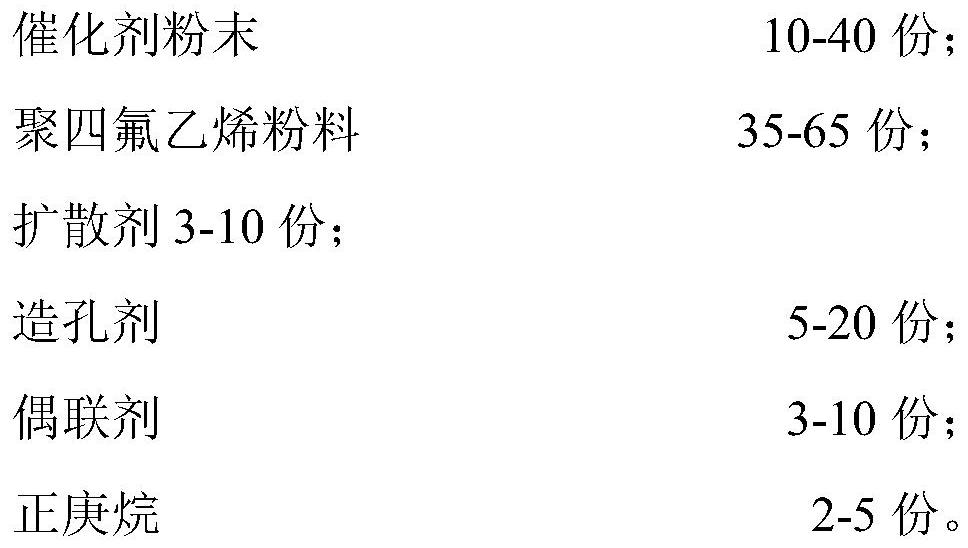

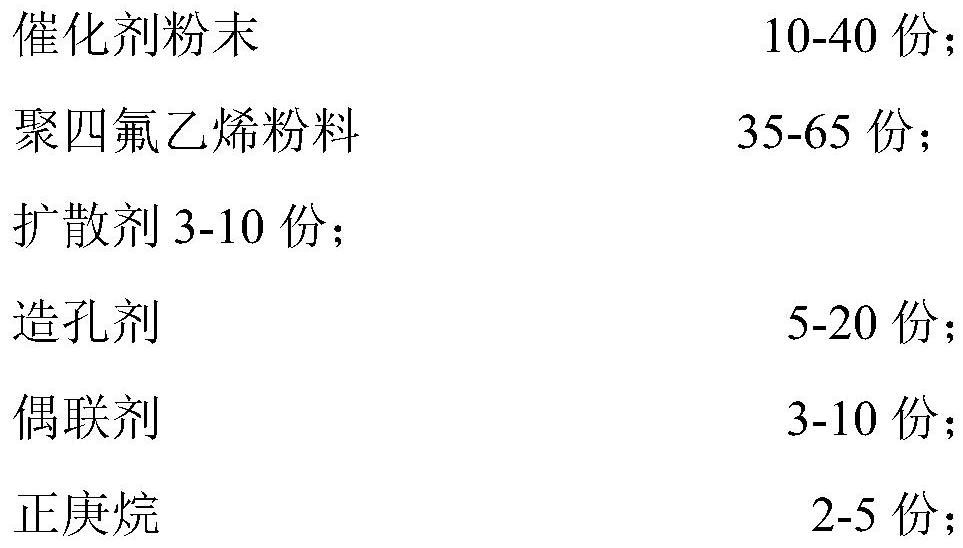

[0041] The preparation method of the low-temperature three-way catalytic function filter material of the present invention, concrete process is as follows:

[0042] 1. Preparation of catalyst powder

[0043] ① Preparation of carrier

[0044] According to the molar ratio of Mg / Al / Si element is 1:1:2, take appropriate amount of MgO2, pseudo-boehmite, SiO 2 Mixed, stirred and ball milled for 2h to make embryo body. The embryo body was prepared into spherical particles with a diameter of 1 cm through an extrusion molding machine. The particles are dried at 100°C for 6 hours, then fired at 1000°C for 10 hours, and MAS composite functional ceramics can be obtained after cooling.

[0045] ② Preparation of precursor solution

[0046]With (Mn-Sn-Nb-Mo) composite oxide as the active component, firstly weigh the appropriate amount of manganese sulfate and tin tetrachloride according to the molar ratio of Mn / Sn / Nb / Mo element of 1:0.1:0.1:0.1 , niobium oxalate, molybdenum nitrate; wit...

Embodiment 2

[0072] The preparation method of the low-temperature three-way catalytic function filter material of the present invention, concrete process is as follows:

[0073] 1. Preparation of catalyst powder

[0074] ① Preparation of carrier

[0075] According to the molar ratio of Mg / Al / Si element is 1:1:2, take an appropriate amount of MgO 2 , Pseudoboehmite, SiO 2 Mixed, stirred and ball milled for 7h to make embryo body. The embryo body was prepared into spherical particles with a diameter of 1 cm through an extrusion molding machine. The particles are dried at 180°C for 5 hours, and then fired at 1300°C for 6 hours to obtain MAS composite functional ceramics.

[0076] ② Preparation of precursor solution

[0077] First, the molar ratio of Mn / Sn / Nb / Mo in the active component is 1:0.5:0.3:0.6, and the molar ratio of Ce / Fe / Co / Ni in the additive is 1:0.2:0.2:0.3, and weigh an appropriate amount Manganese sulfate, tin nitrate, molybdenum trichloride, and niobium oxalate are used a...

Embodiment 3

[0092] The preparation method of the low-temperature three-way catalytic function filter material of the present invention, concrete process is as follows:

[0093] 1. Preparation of catalyst powder

[0094] ① Preparation of carrier

[0095] According to the molar ratio of Mg / Al / Si element is 1:1:2, take an appropriate amount of MgO 2 , Pseudoboehmite, SiO2 Mixed, stirred and ball milled for 5h to make embryo body. The embryo body was prepared into spherical particles with a diameter of 1 cm through an extrusion molding machine. The particles are dried at 150°C for 5 hours, and then fired at 1200°C for 7 hours to obtain MAS composite functional ceramics.

[0096] ② Preparation of precursor solution

[0097] First, the molar ratio of Mn / Sn / Nb / Mo in the active component is 1:0.4:0.25:0.75, and the molar ratio of Ce / Fe / Co / Ni in the additive is 1:0.2:0.1:0.25, and weigh an appropriate amount The active components of manganese nitrate, molybdenum nitrate, tin nitrate, and niob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com