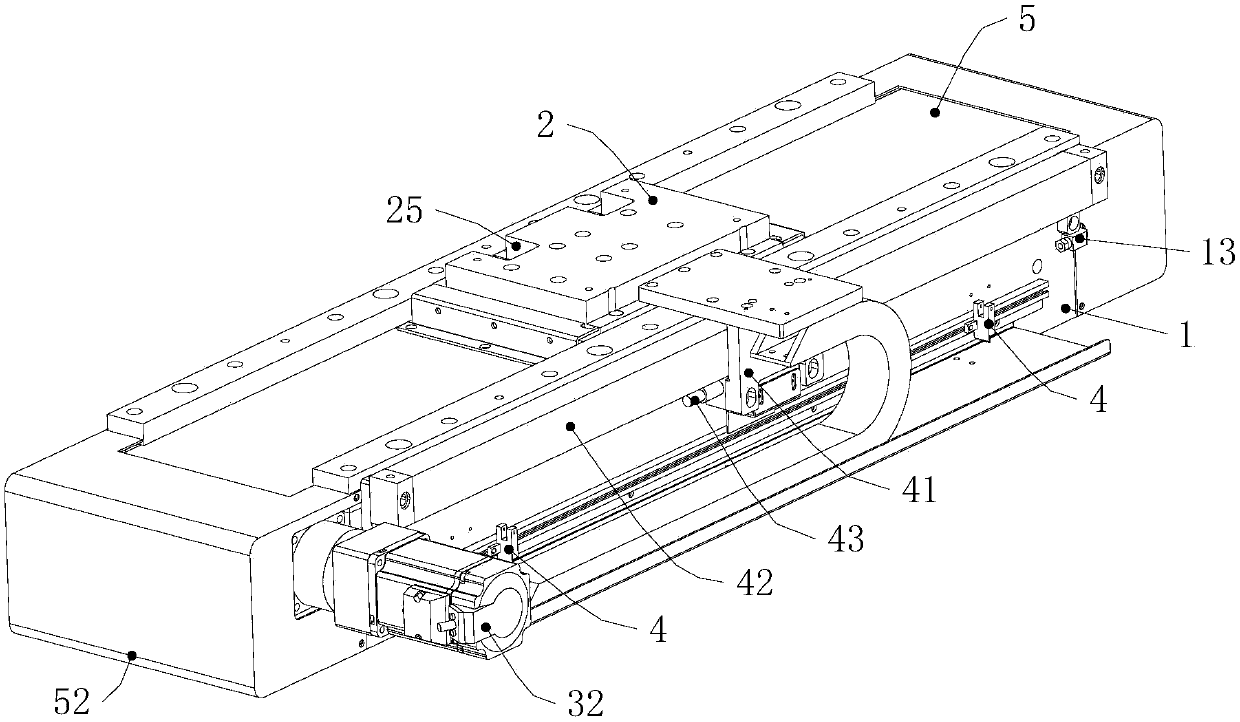

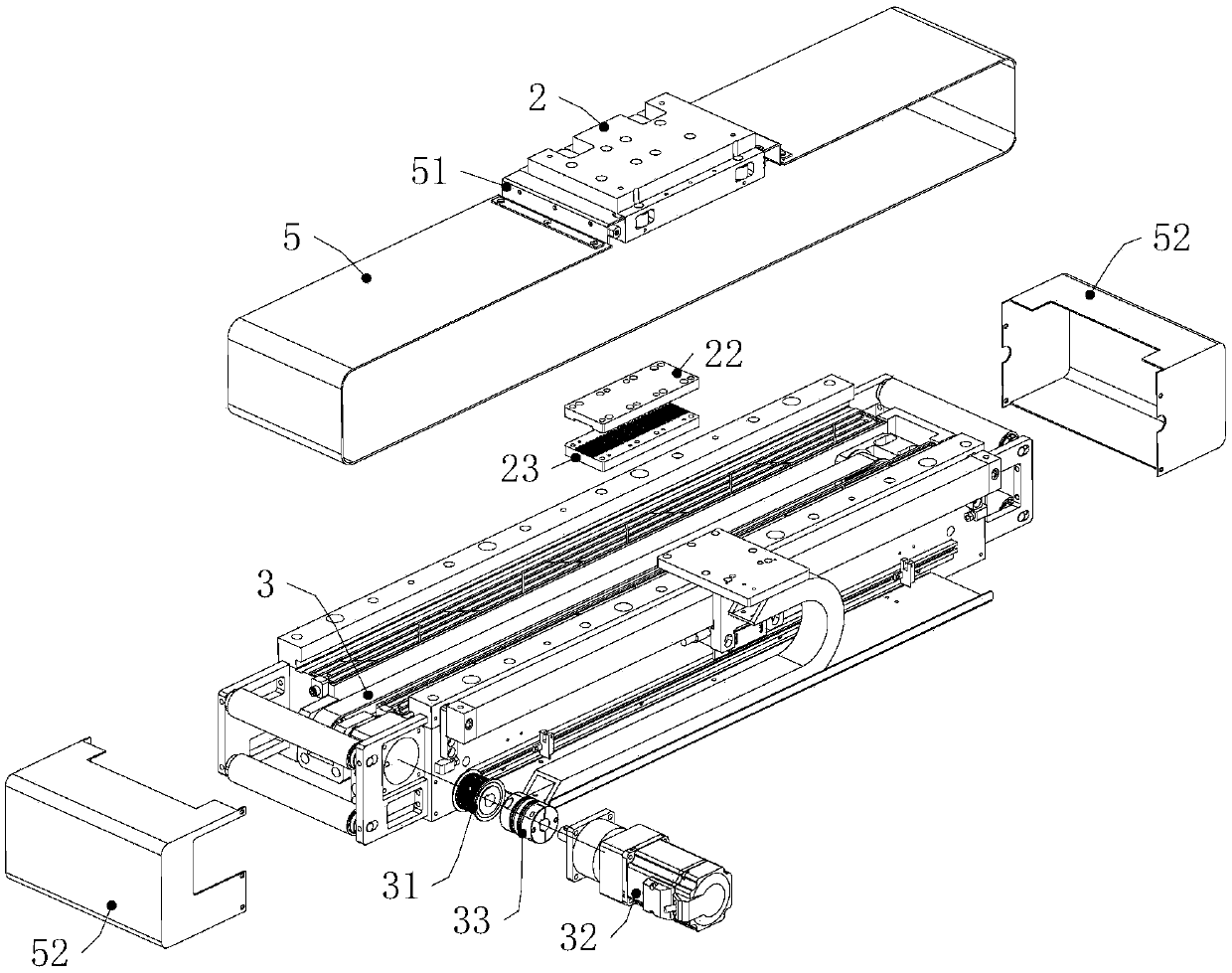

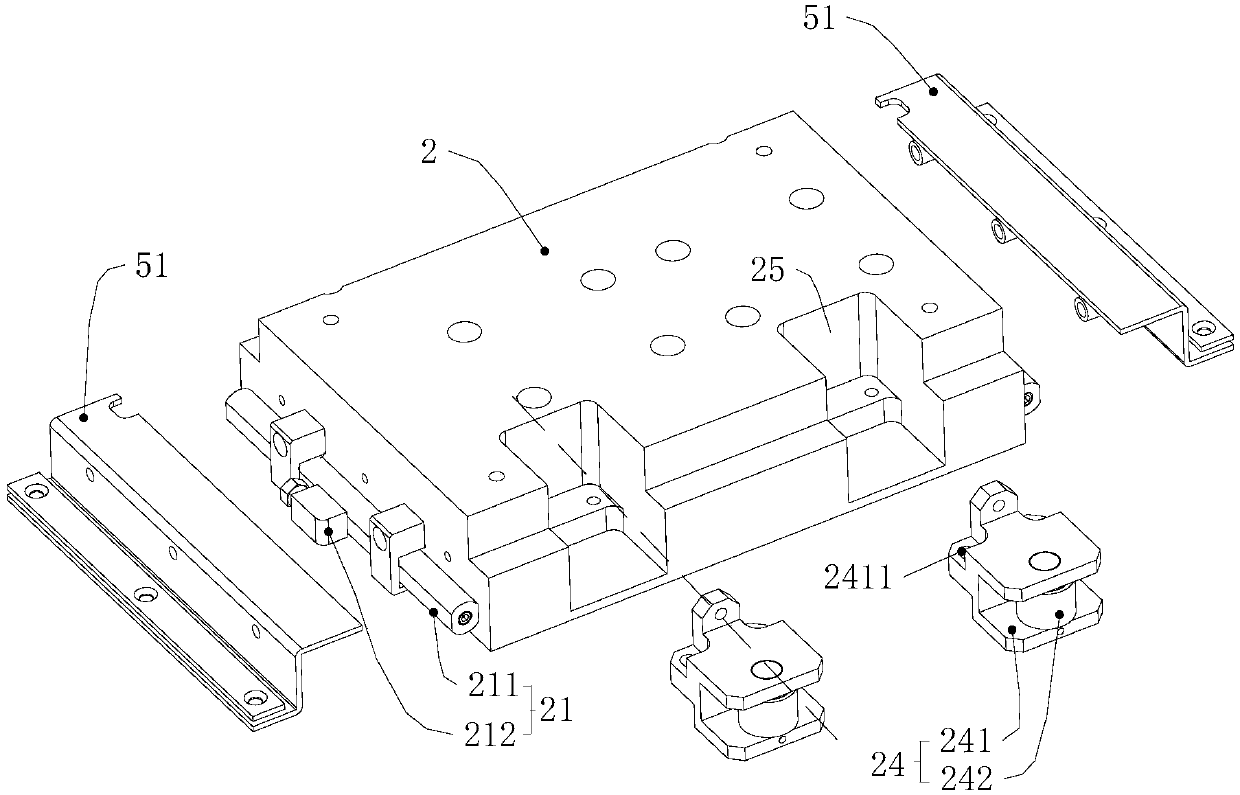

Slide table, coating machine and gluing method

A coating machine and sliding table technology, which can be applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc., can solve problems such as low precision, and achieve the effects of improving production efficiency, improving quality, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0098] Furthermore, please also refer to Figure 9 to Figure 11 As a specific embodiment of the coating machine provided by the present invention, the lifting mechanism 20 includes a lifting block 201 that is slidably connected to the support 10, and the top of the support 10 is provided with a lifting cylinder 202, and the output shaft of the lifting cylinder 202 is connected to The lifting block 201, the position sensing switch 2021 on the lifting cylinder 202 is used to sense whether the output shaft of the lifting cylinder 202 has risen to the preset highest position or dropped to the preset lowest position, the position sensing switch 2021 is connected to the controller and controlled by the controller .

[0099] The lifting cylinder 202 arranged symmetrically on the bracket 10 makes the lifting cylinder 202 drive the lifting block 201 to rise or fall more stably, and the position sensor switch 2021 detects whether the cylinder 502 rises to the preset highest position or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com