Biconical aerostatic rotary table

A gas static pressure, biconical technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of high turntable height and large turntable quality, and achieve the effect of low overall height, low mass of rotating body, and high rotation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

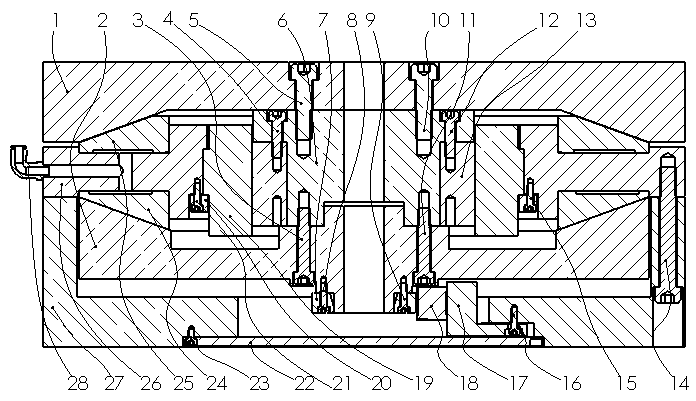

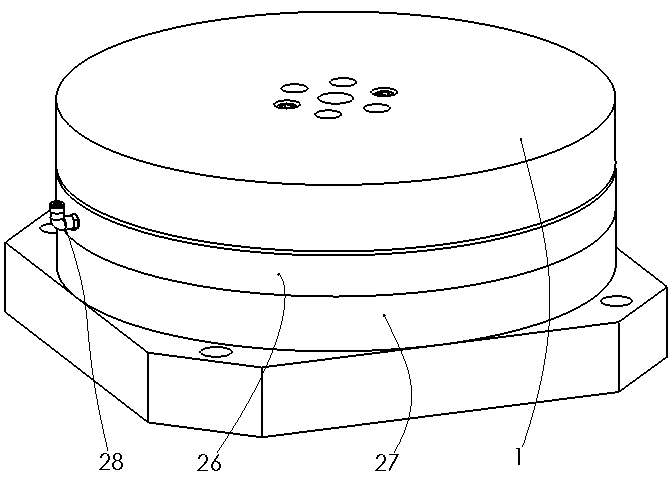

[0023] Example: such as Figures 1 to 2 As shown, a double-cone gas static pressure turntable includes a turntable table top 1, a torque motor rotor mounting shaft 6 fixedly connected to the turntable table top 1 through the second screw 5 and the fifth screw 10, and the first screw 4 and the seventh screw. The screw 12 is sleeved on the torque motor rotor 13 connected to the outside of the torque motor rotor installation shaft 6, and the torque motor stator 19 is sleeved on the outside of the torque motor rotor 13, and also includes an air bearing connection assembly, an angular displacement measurement assembly and a turntable base 27. The air flotation connection assembly includes an upper static pressure block 25, a static pressure block bonding seat 26, a lower static pressure block 24 and a gas pipe joint 28, and the angular displacement measurement assembly includes a lower static pressure plate 2, a circular grating 7, a reading head installation Seat 17 and reading he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com