Packing film and rewinding device using packing film

A driving device, wrapping technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as affecting accuracy, increasing the difficulty of disassembly, and loss of parts, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

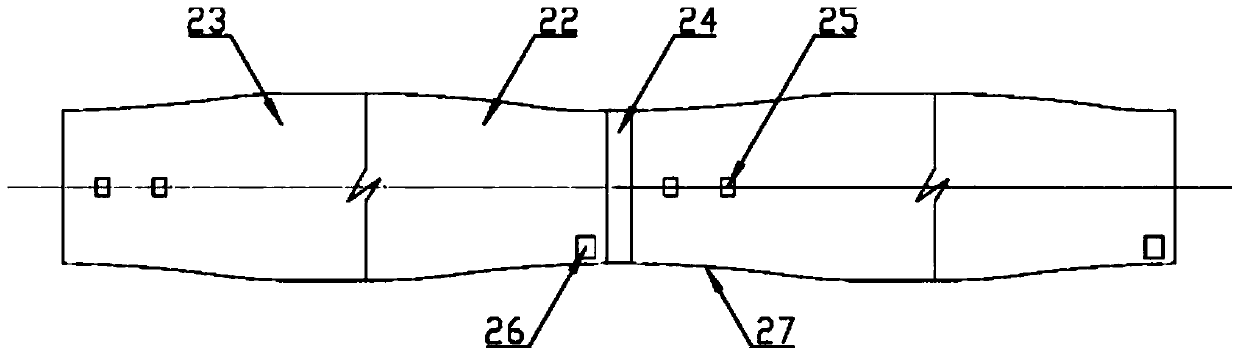

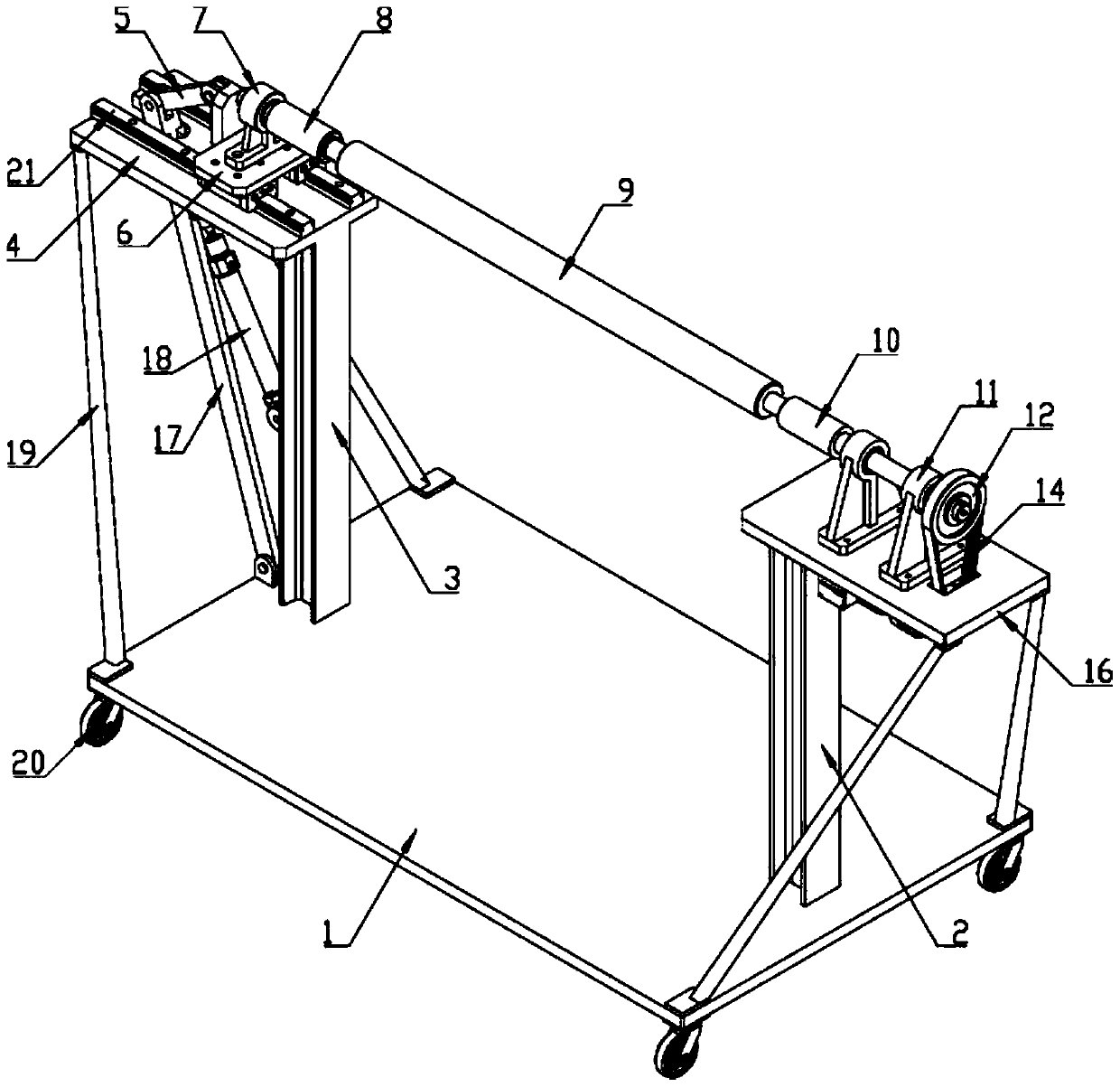

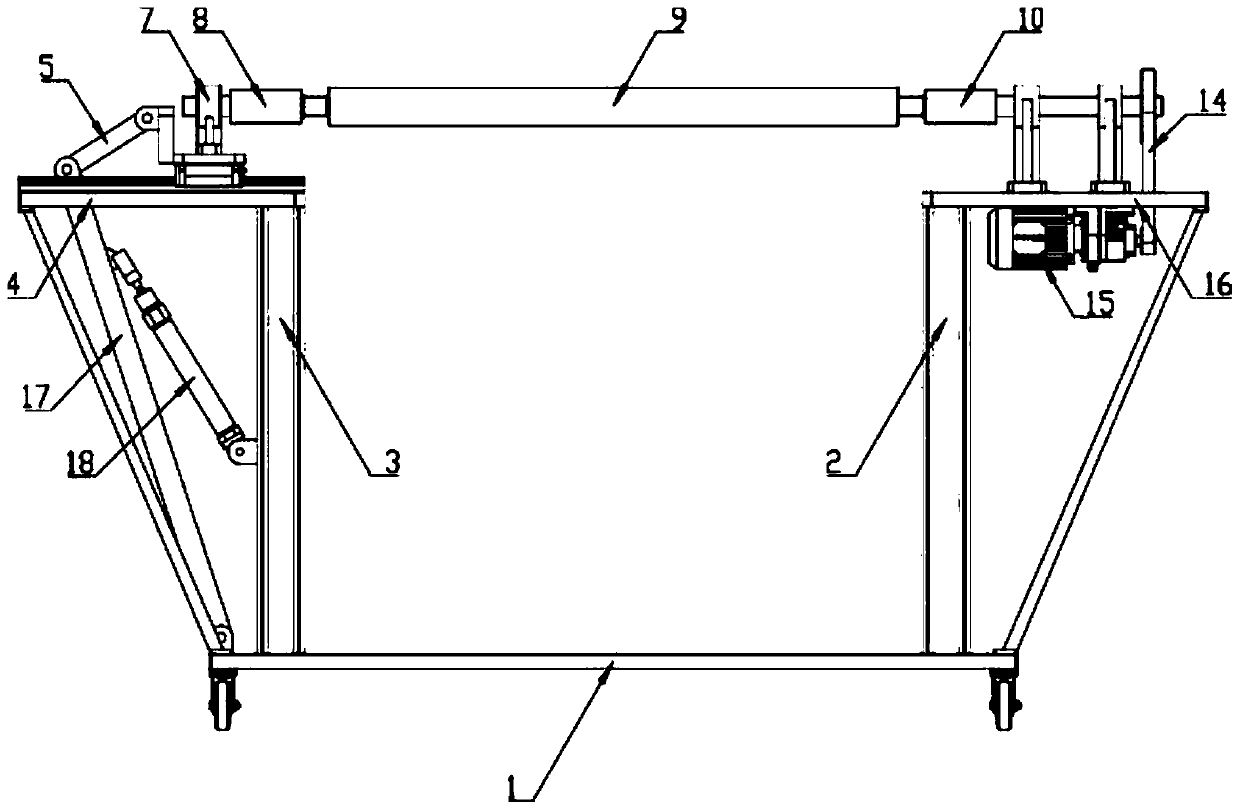

[0024] Such as Figures 1 to 5 As shown, the packaging film in the present invention is an improvement on the basis of the invention publication with the application number 2017103078707. Specifically, the packaging film has continuously alternating adhesive regions 22 and non-adhesive regions 23, and adjacent adhesive regions 22 and the non-adhesive area 23 are connected by a double-sided adhesive joint 24, and the bonding and working principle of the double-sided adhesive joint will not be repeated. The sticky area 22 is provided with an induction label 26 for the braking of the packaging equipment and an electronic label 25 recording the information of the packaged object. After the induction label 26 on the packaging film is scanned by the packaging equipment, the packaging equipment is braked to stop the double-sided adhesive joint. At the set position, the adhesive area 22 and the non-adhesive area 23 are narrowed at the junction of the double-sided adhesive joint 24 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com