Pneumatic brake

A technology of pneumatic brakes and brake pads, applied in the direction of brake types, brake components, brake actuators, etc., can solve problems such as untimely braking of high-speed pipe stranding machines, and achieve improved braking effect, improved operating life, and ease of The effect of braking delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

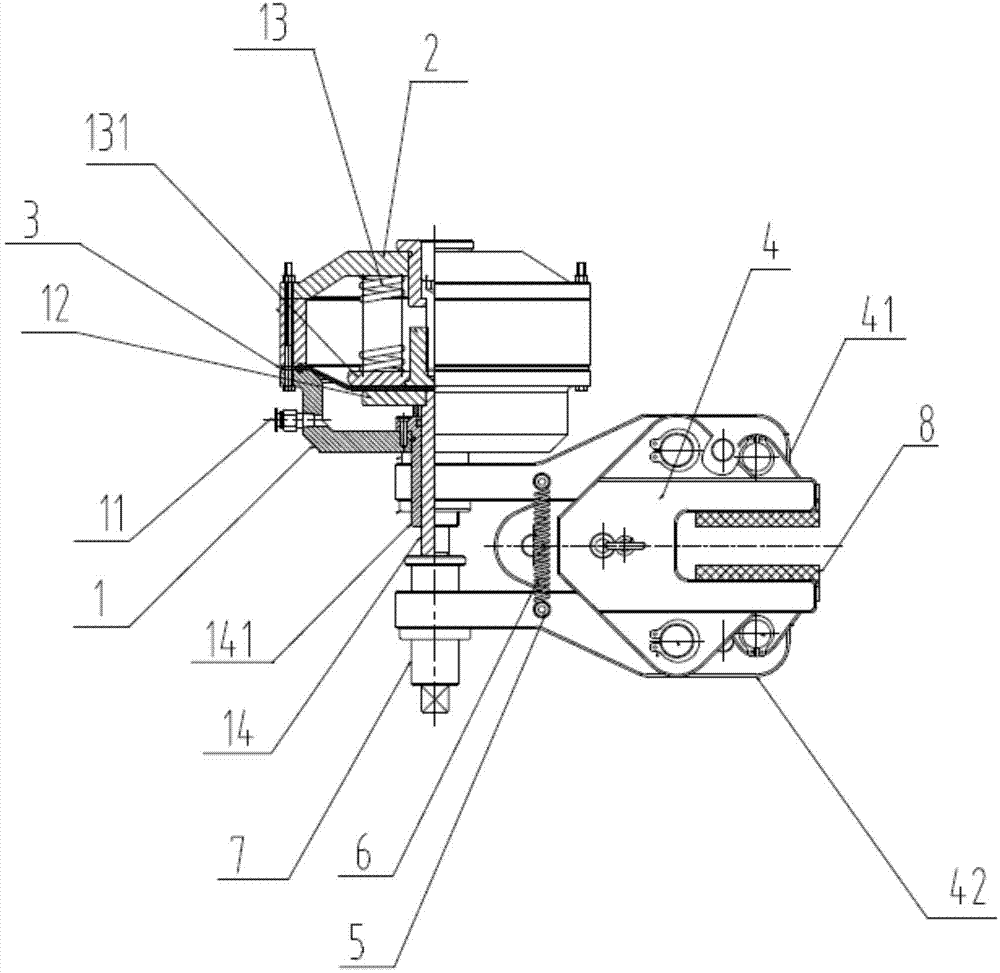

[0016] Such as figure 1 As shown, the pneumatic brake includes a cylinder block 1 and a cylinder head 2, an air source interface 11 is provided on the cylinder block 1, a pressure plate 12 and a compression spring 13 are installed in the cylinder block 1, and a spring top plate is connected to the compression spring 13 131, a sealing sheet 3 is provided between the pressure plate 12 and the spring top plate 131; a sleeve 14 is also connected to the lower end of the cylinder block 1, and a push rod 141 is arranged inside the sleeve 14, wherein the sleeve 14 is fixed On the cylinder block 1, the push rod 141 can move up and down in the sleeve 14; the other end of the sleeve 14 is fixed on the brake frame 4, and the brake frame 4 includes an upper brake pad 41 and a lower brake pad 42. Two brake screws 5 are respectively fixed on the upper brake pad 41 and the lower brake pad 42, and a brake spring 6 is clamped between the upper and lower brake screws 5, wherein the lower brake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com