A kind of preparation method of ceramic layer and thus obtained ceramic layer and thermal barrier coating thereof

A technology of thermal barrier coating and ceramic layer, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of high strain tolerance, high fracture toughness, low thermal conductivity of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

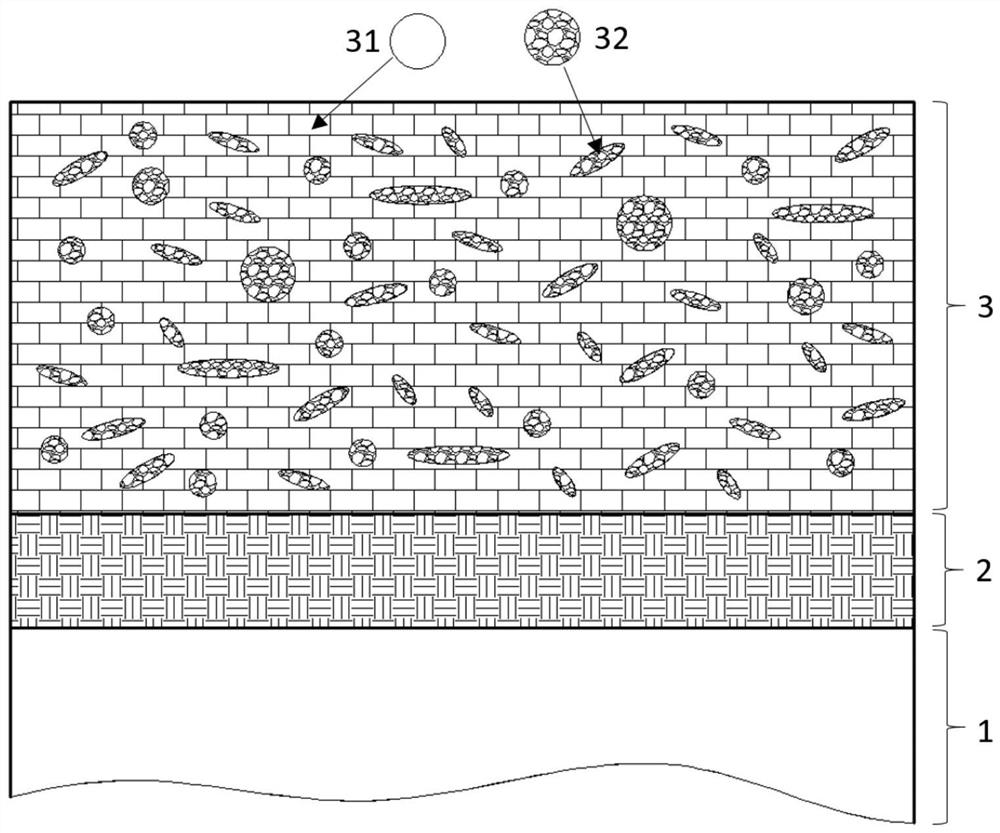

[0028] The method for preparing a thermal barrier coating with a ceramic layer according to the present invention firstly includes providing a nickel-based alloy as a base layer 1, such as figure 1 shown. In this embodiment, the base layer 1 is IN738 nickel-based superalloy. Preferably, before performing subsequent steps, the surface of the base layer 1 is first subjected to sandblasting and ultrasonic cleaning with acetone.

[0029] The method for preparing a thermal barrier coating with a ceramic layer according to the present invention next comprises providing an adhesive layer 2 on a base layer 1, as figure 1 shown. In this embodiment, NiCoCrAlYTa metal powder produced by SulzerMetco is selected as the material of the bonding layer 2, and the bonding layer 2 is prepared by plasma spraying (APS-2000).

[0030] The method for producing a ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com