A kind of fabric non-water printing and dyeing equipment and method thereof

A printing and dyeing equipment and fabric technology, which is applied in the field of fabric non-water printing and dyeing equipment, can solve the problems of many types of chemicals, small scope of application, water resource consumption, etc., achieve the effects of shortening dyeing time, easy maintenance and replacement, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

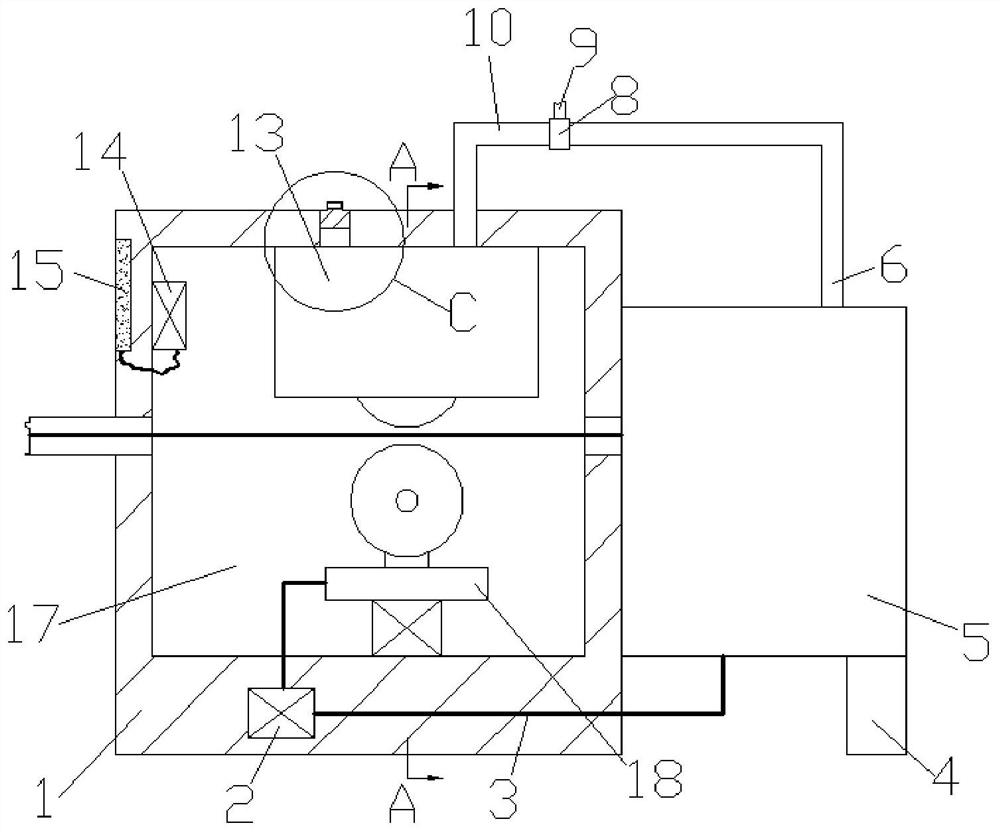

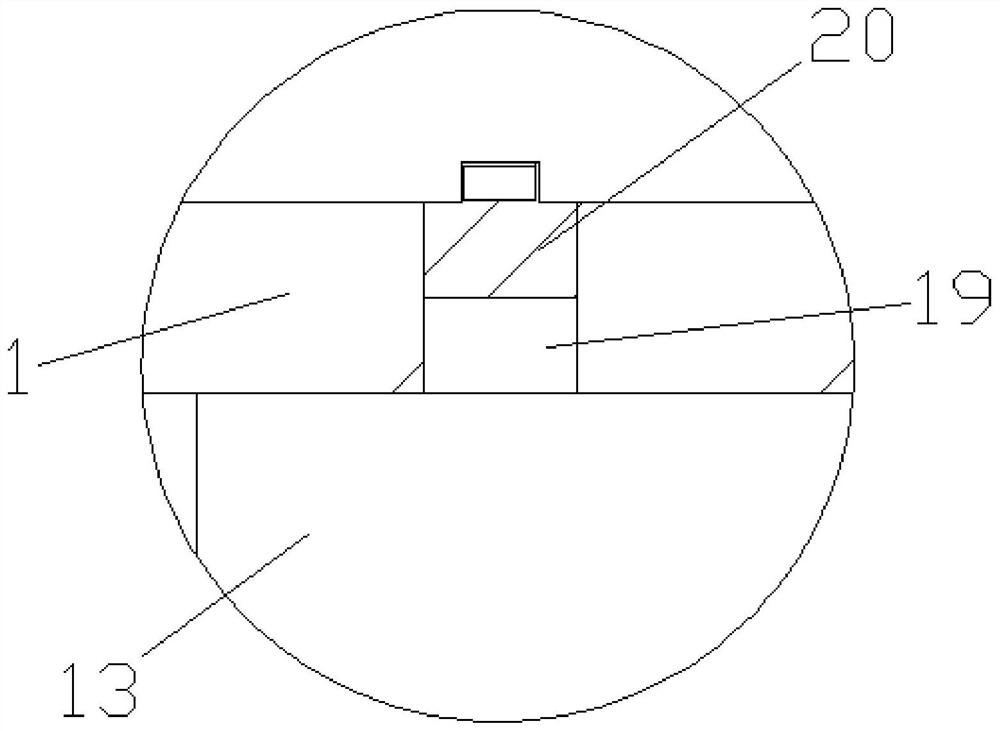

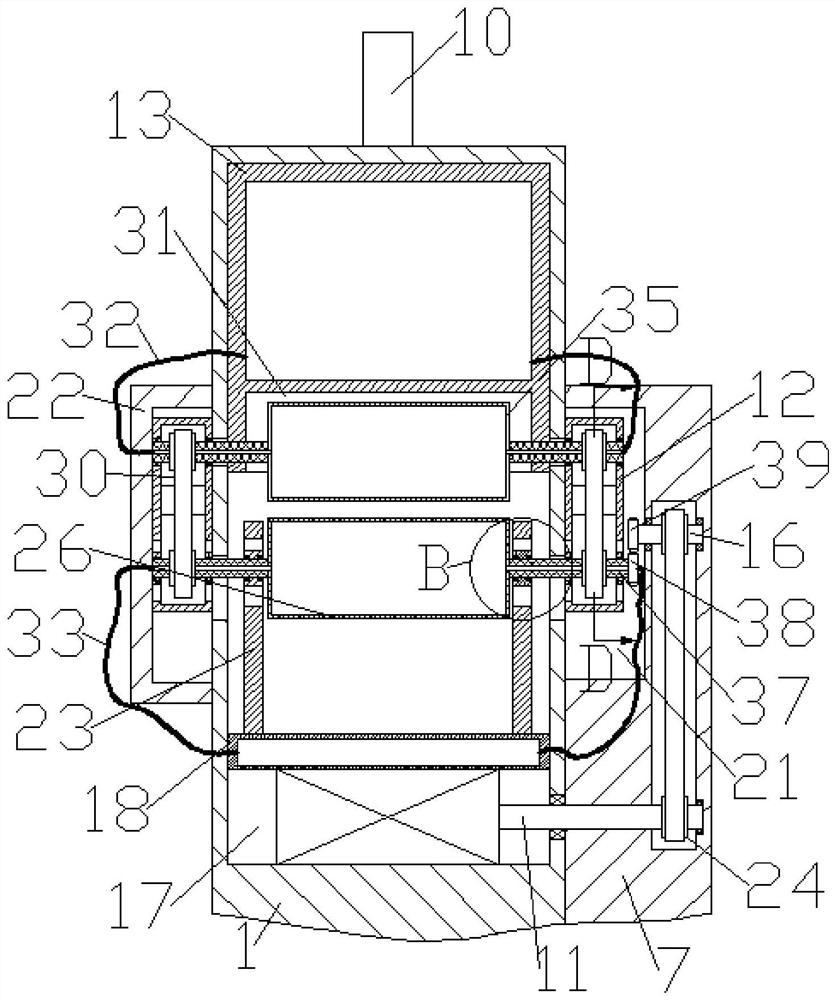

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0033] Such as Figure 1-5 The shown waterless printing and dyeing equipment for fabrics includes a fuselage 1, a dyeing chamber 17 is provided in a hollow inside the fuselage 1, and a cloth guide pipe is provided on the left end wall of the dyeing chamber 17 to communicate with the outside world, and the The lower end wall of the dyeing chamber 17 is fixedly provided with a motor, and the upper end surface of the motor is fixedly provided with a first dyeing mechanism, and the corresponding position on the upper side of the first dyeing mechanism is provided with a second dyeing mechanism. The upper end wall of the chamber 17 is fixed to ensure that the upper and lower surfaces of the fabric are printed and dyed simultaneously and the smoothness of the fabric running in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com