Monitoring method of abnormal working condition of pumping unit

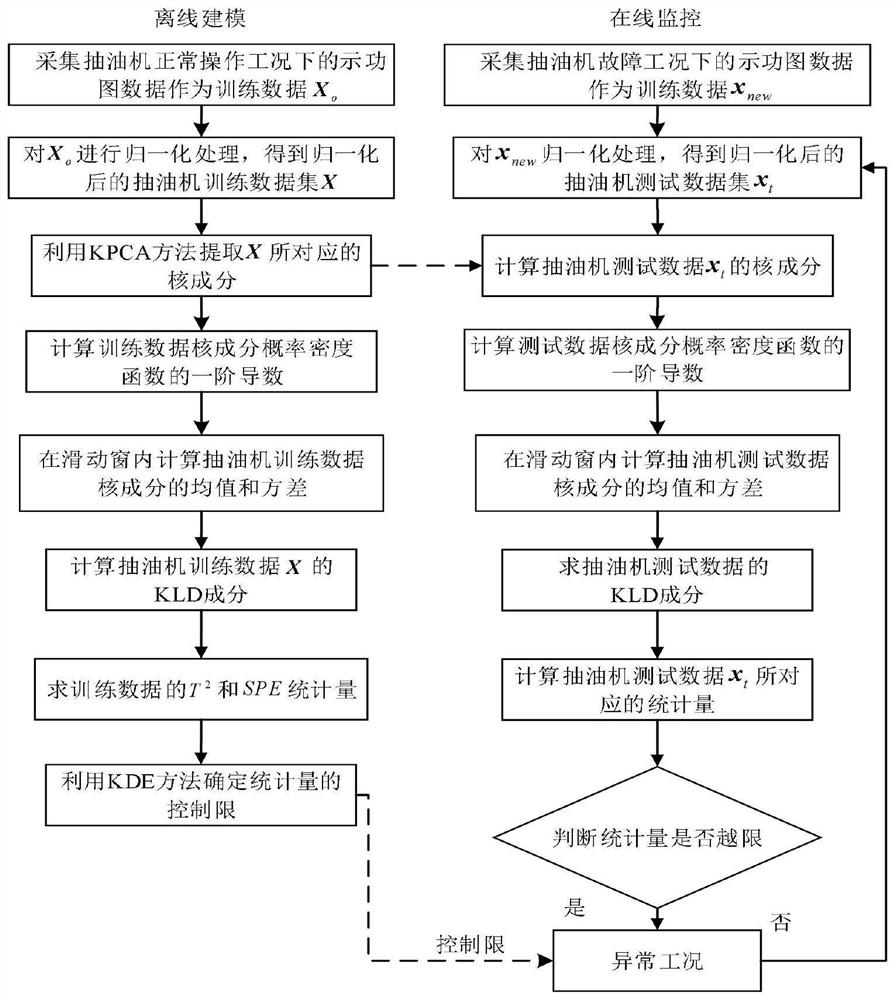

A technology for abnormal working conditions and pumping units, which is applied in the field of industrial system working condition monitoring, can solve problems such as low fault detection performance, and achieve the effects of improving fault detection results, improving monitoring capabilities, and overcoming poor monitoring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

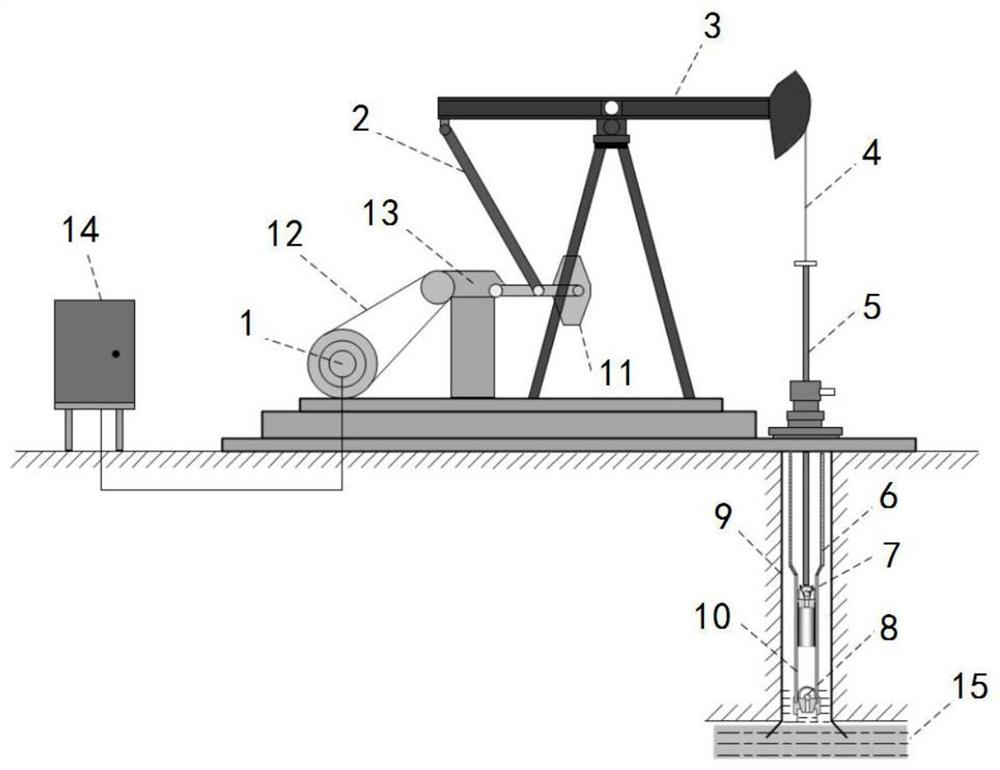

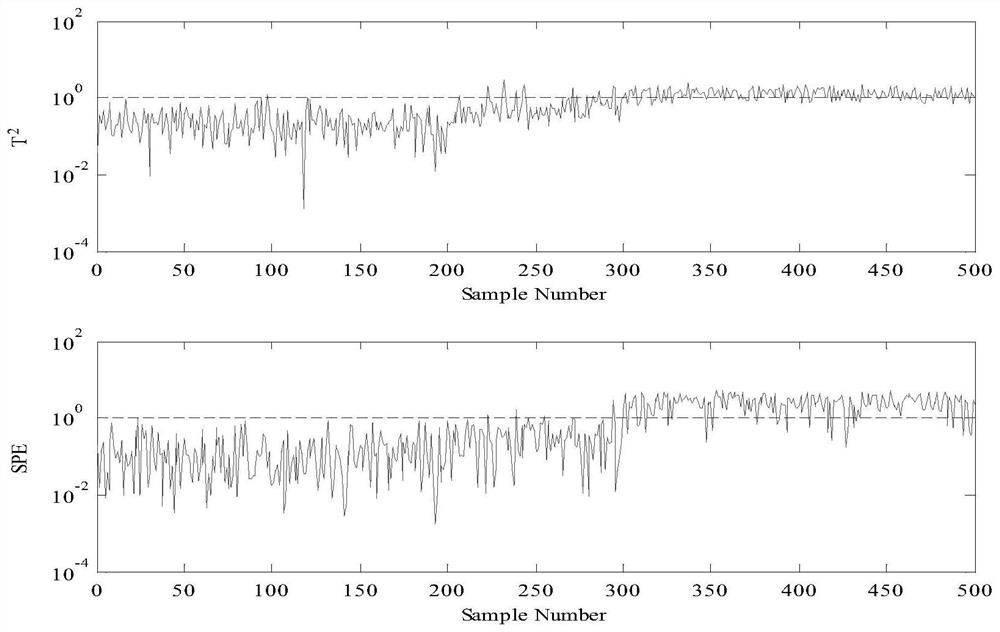

[0153] Rod pump oil pumping (hereinafter referred to as: SRP) system is the main unit of oil extraction and is widely used in the oil extraction industry. see figure 2 , SRP system consists of motor 1, connecting rod 2, beam 3, oil pump and other components. When the system is running, the power generated by the motor 1 makes the sucker rod 5 reciprocate up and down through the connecting rod 2, the traveling beam 3 and the suspension rope 4, and then transmit the power to the downhole part. On and off, the liquid in the well continuously enters the pump barrel 10, thereby ascending into the oil pipe 6, and finally reaching the surface. During the operation of the pumping unit, the dynamometer diagram is the most common means of collecting status data. In this example, the feature extraction of the dynamometer diagram is carried out according to the gravity center decomposition method and the valve working position, and 7 dynamometer diagram features are collected as monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com