Temperature difference type automatic temperature-adjusting water mixing valve

A water mixing valve and temperature difference technology, which is applied in the field of automatic temperature-adjusting water mixing valve, can solve the problems of unusable water resources, affecting the water pressure state of water supply pipes, and waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

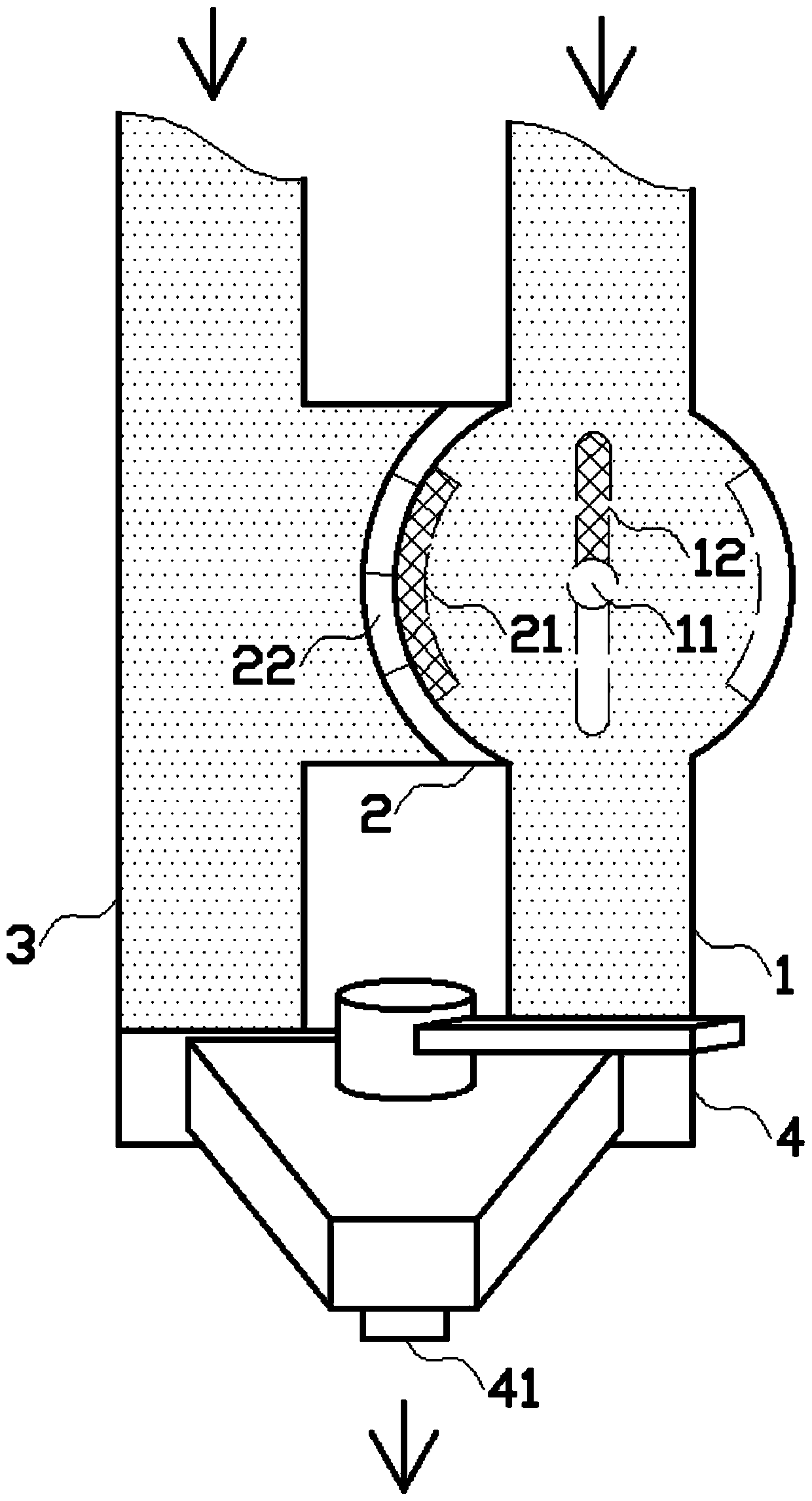

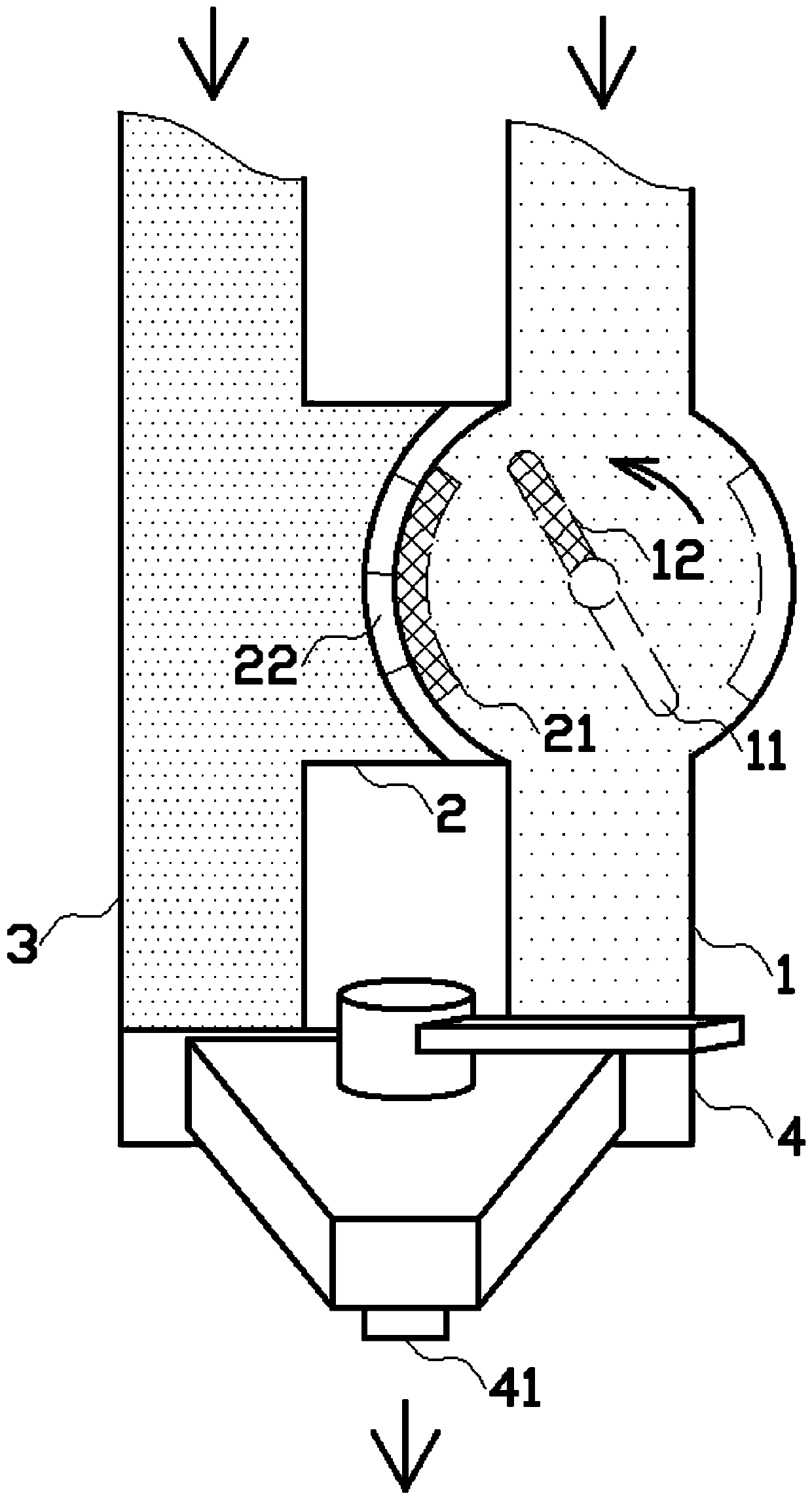

[0012] Such as figure 1 , figure 2 As shown in the embodiment, the temperature difference automatic temperature adjustment mixing valve is a kind of flow switch that generates electricity through the temperature difference between the cold water pipe and the hot water pipe, thereby triggering the electromagnetic induction phenomenon, and then using the generated magnetism to adjust the flow of the hot water pipe. Size, so as to achieve the function of adjusting the mixing ratio of cold and hot water, it includes a hot water module 1, a cold water module 3, an induction module 2 and a drainage module 4; the hot water module 1 includes a hot water pipe, and the hot water pipe Including a hot water cavity, the shape of the hot water cavity is round cake shape, the hot water cavity is installed between the water inlet end and the water outlet end of the hot water pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com