Efficient serpentine tube type heat exchanger

A tubular heat exchanger and serpentine tube technology, which is applied in the heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of high water supply pressure, inability to meet design requirements, and inability to accurately calculate the strength of the tube sheet and other problems to achieve the effect of improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

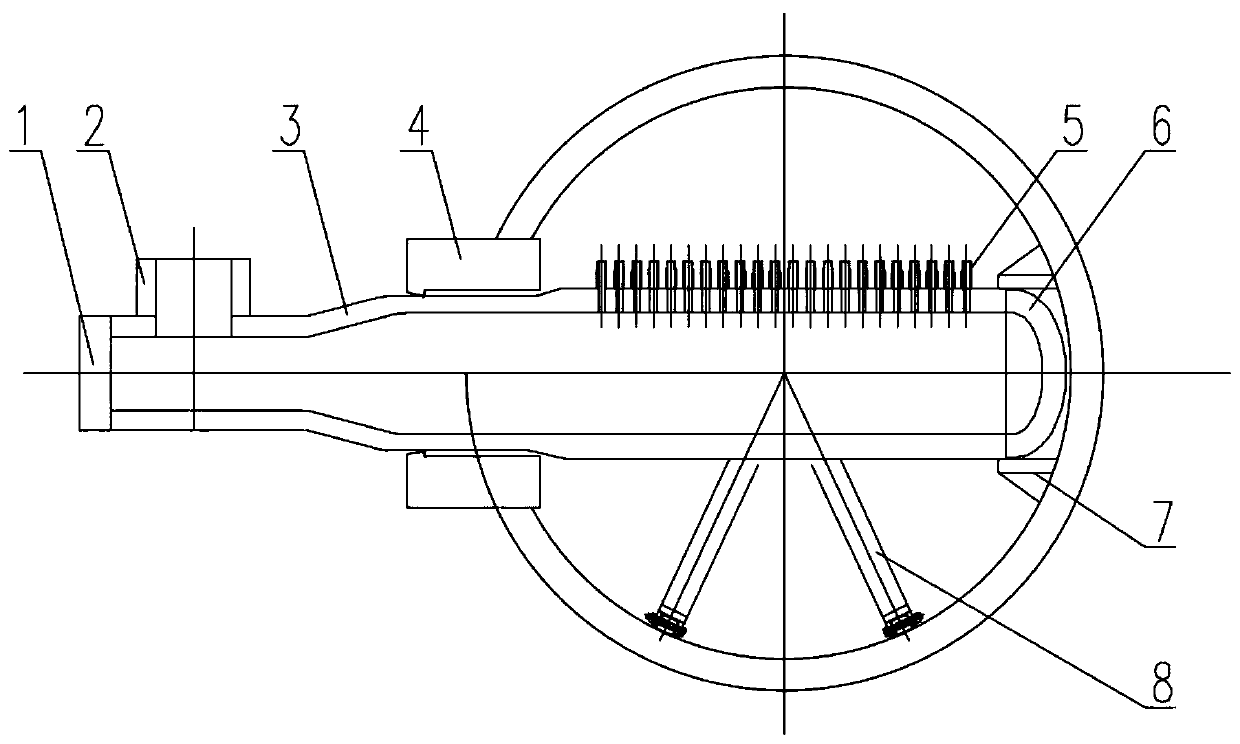

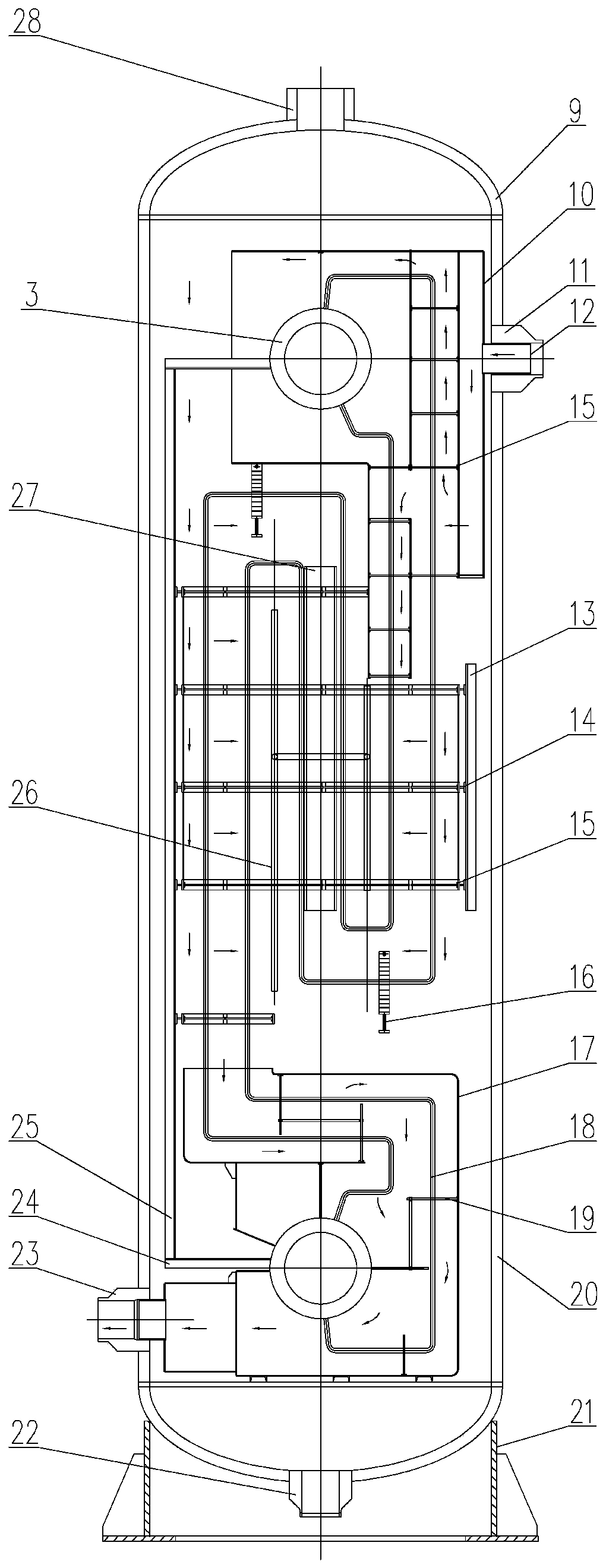

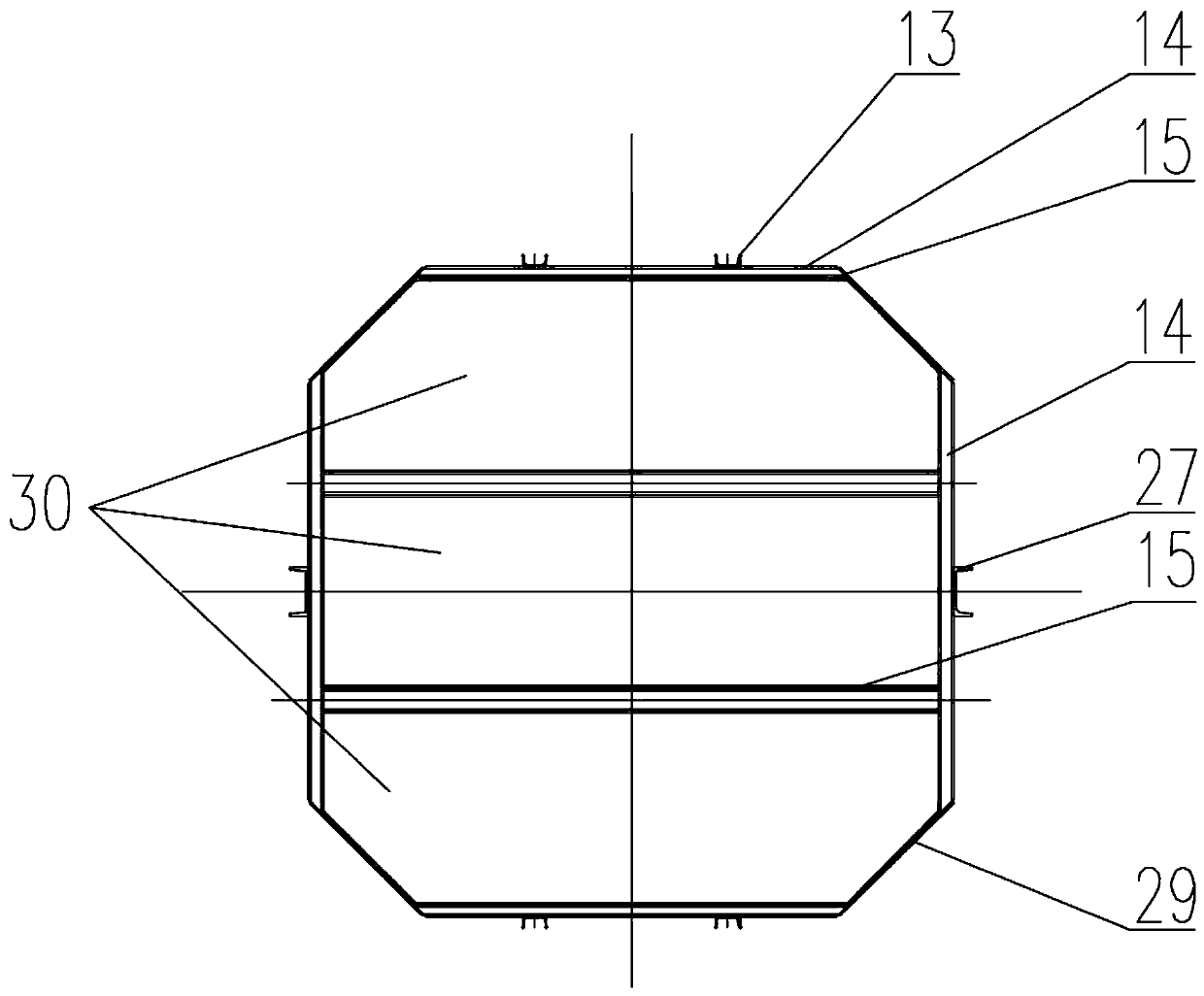

[0042] In this embodiment, both the header assembly and the serpentine piping system are arranged in the casing, the support plate 7 in the header assembly is connected with the cylinder body 20 on the casing, and the casing is connected with the expansion joint 4 in the header assembly. The serpentine piping system connects the upper and lower header assemblies, and the header pipe joint 5 in the header assembly is connected with the serpentine pipe 18 in the serpentine piping system.

[0043] Such as figure 1 As shown, the header assembly is composed of a flat cover 1, a water supply pipe 2, a header pipe 3, an expansion joint 4, a header pipe joint 5, a head 6, a support plate 7 and a bracket 8; one end of the header pipe 3 is provided with The flat cover 1 is provided with a head 6 at the other end, and the head 6 is fixedly supported by the support plate 7. The upper part of the header pipe 3 near the end of the flat cover 1 is provided with a water supply connection pipe...

Embodiment 2

[0051] Such as figure 2 As shown, the arrow in it indicates the direction of superheated steam flow. When the device is working, the feed water enters the header pipe 3 through the feed water connection pipe 2 of the header assembly arranged on the upper side, and the feed water enters the header pipe 3 and enters the pipe through the serpentine pipe 18. Inside the system, the feed water flows out of the serpentine pipe 18 after exchanging heat in the serpentine pipe system and enters the header pipe 3 in the header assembly arranged below. The superheated steam enters the superheated section cladding 10 of the serpentine piping system through the steam inlet 11 of the shell, and the superheated steam flows into the piping system through the superheating section cladding 10, contacts the outer surface of the serpentine tube 18, and the superheated steam passes through the cladding Partition strips 19, after heat exchange, the steam enters the area between the cylinder body an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com