Connecting structure of story-added steel column base

A technology for connecting structures and steel columns, which is applied to building components, building structures, building maintenance, etc. It can solve the problems that the rigidity of the column foot cannot meet the use requirements, and achieve the effects of improved seismic performance, convenient construction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

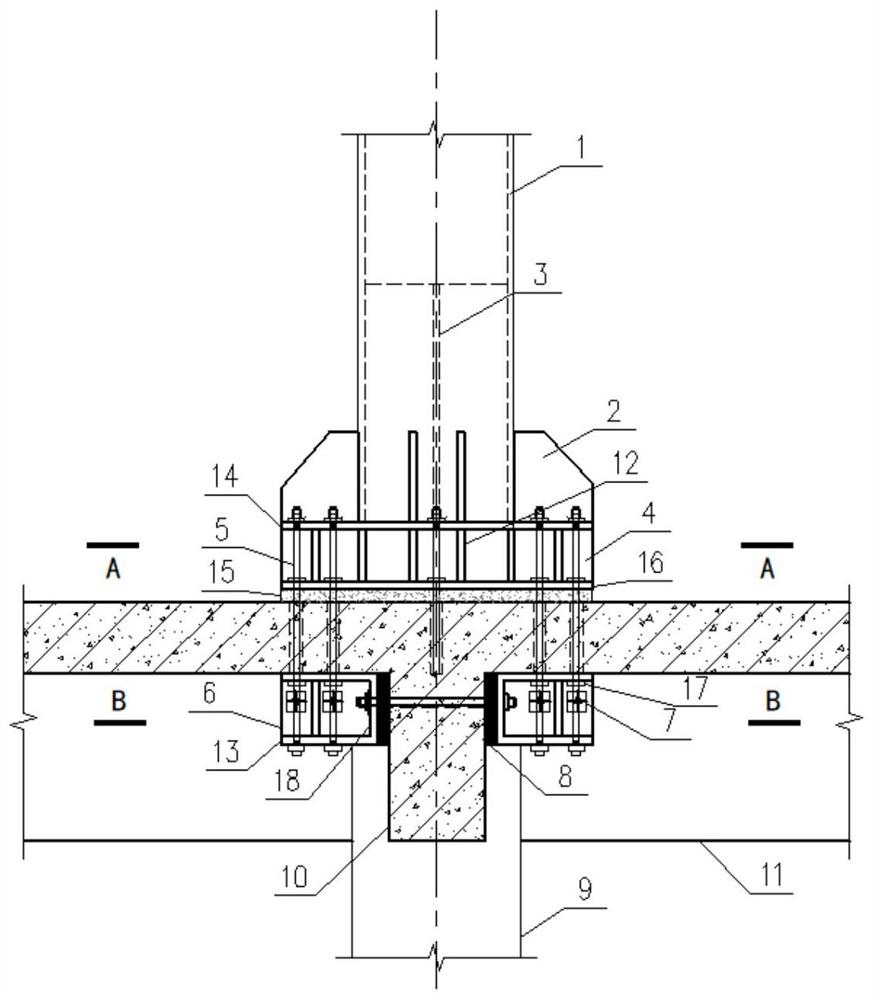

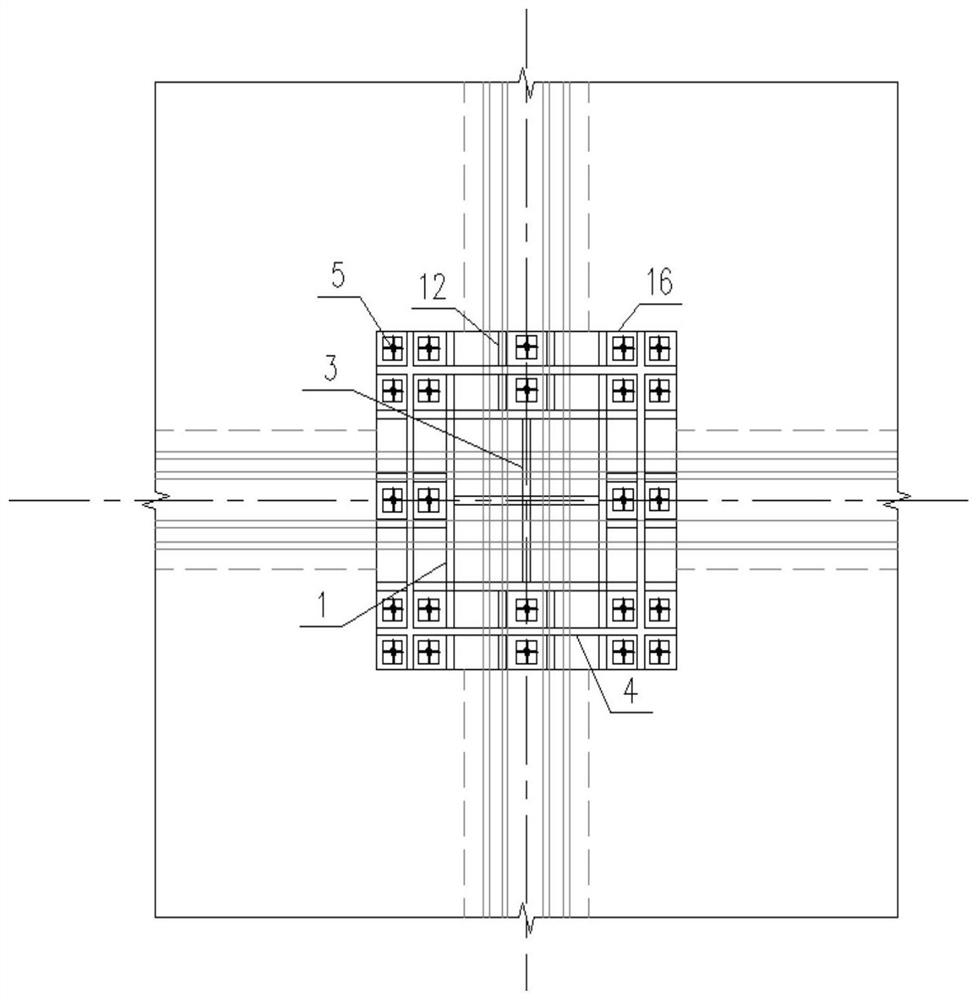

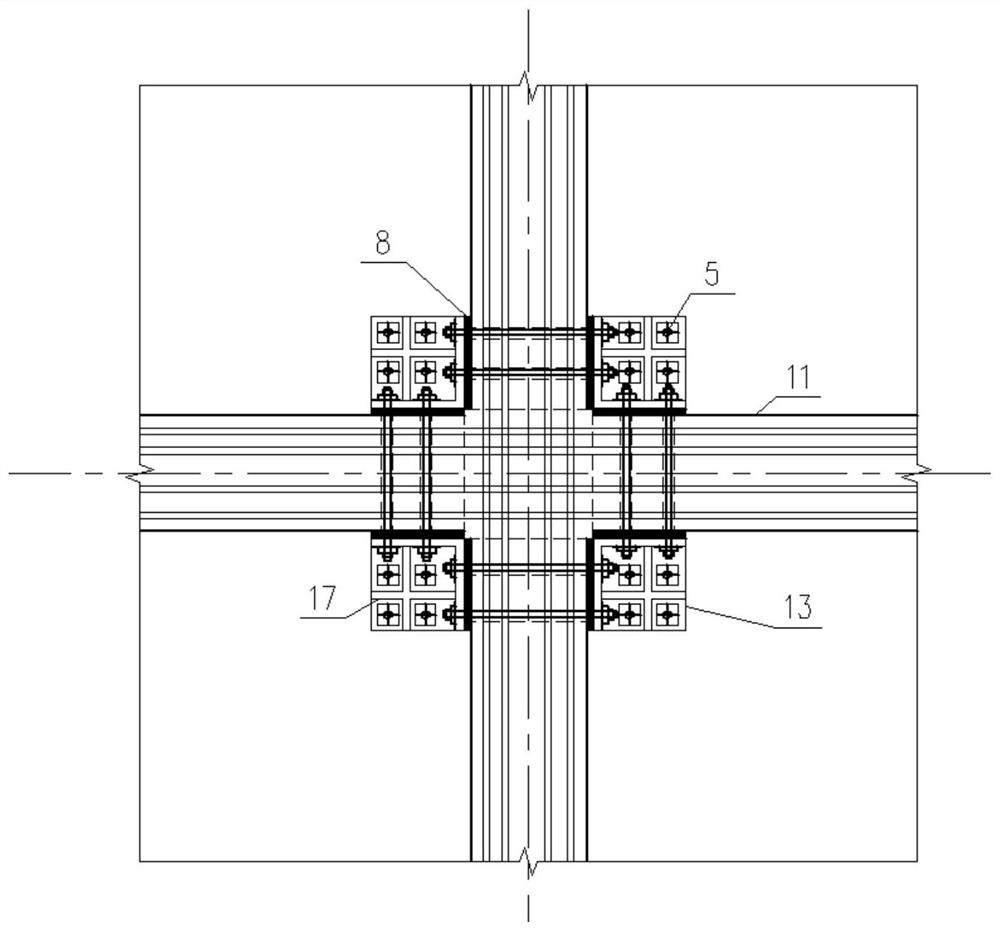

[0030] The connection structure of the added layer steel column foot used in this embodiment refers to Figure 1 to Figure 4 , specifically:

[0031] The connection structure of the added layer steel column foot provided by this implementation includes: steel column 1, stiffened connecting plate 2, buckling-resistant steel plate 3, shoe beam web 4, positioning anchor bolt 5, plate lower support rib plate 6, through Beam anchor bolt 7, caulking pressure-bearing material 8, prestressed member (built structural column) 9, built prestressed beam 10, built structural plate 11, shoe beam rib plate 12, lower support steel plate 13, shoe beam Horizontal plate 14, column base cushion 15, column base plate 16, parallel iron 17, lower support side plate 18.

[0032] The upper column bottom of the added steel column foot is provided with the foot plate 16, the shoe beam web 4 is welded to the steel column 1 and the column foot bottom plate 16, and the shoe beam transverse plate 14 is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com