Method for realizing U-shaped width monitoring of chemical cargo ship by using total station

A chemical tanker and total station technology, applied in the direction of instruments, height/level measurement, measurement devices, etc., can solve the problems such as the inability to accurately detect the change of the half width of the lower mouth of the U-shaped main section, so as to reduce the construction risk and improve the Data accuracy, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A method for monitoring the U-shaped width of a chemical tanker by using a total station, the method comprising the following steps:

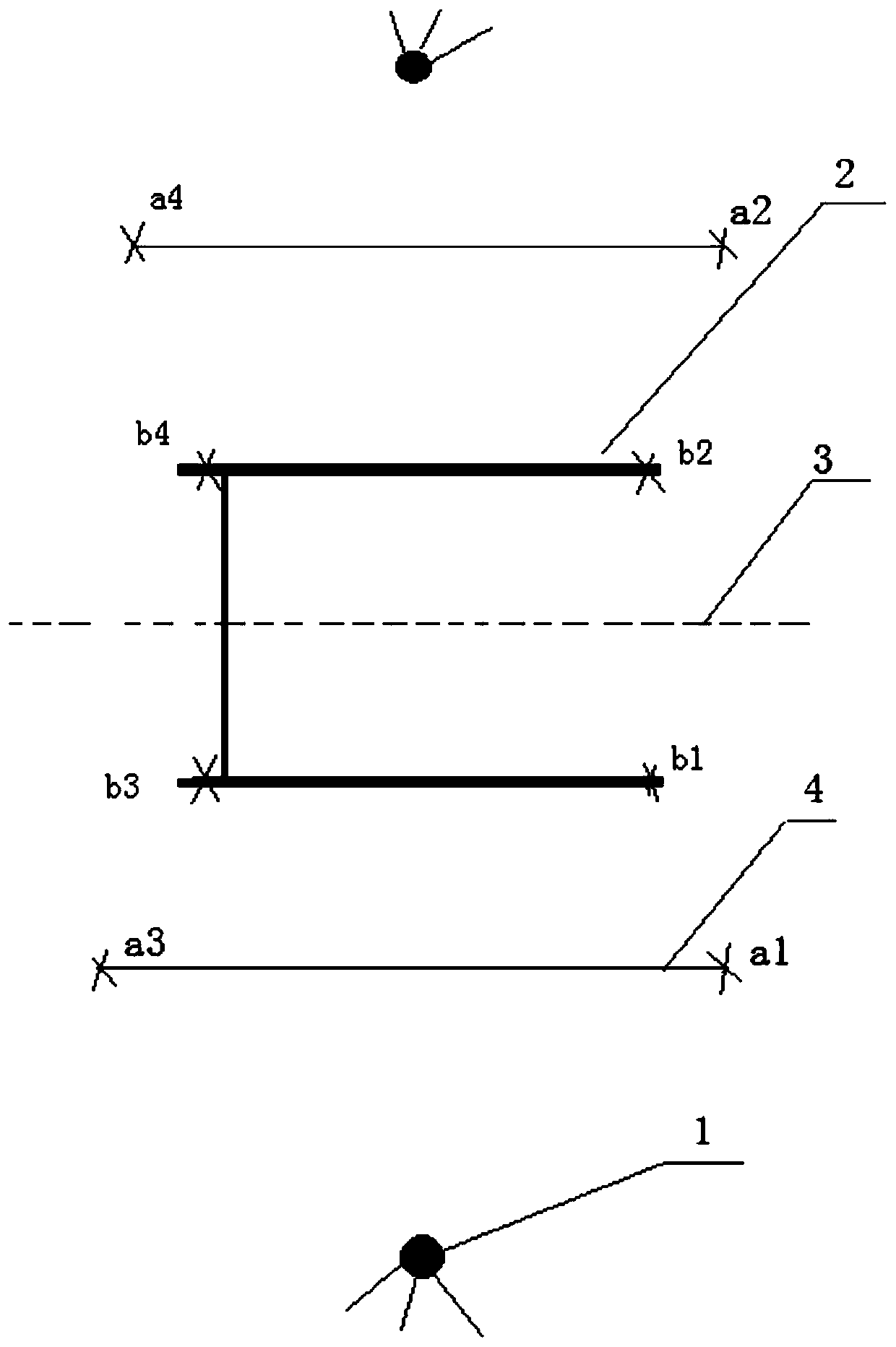

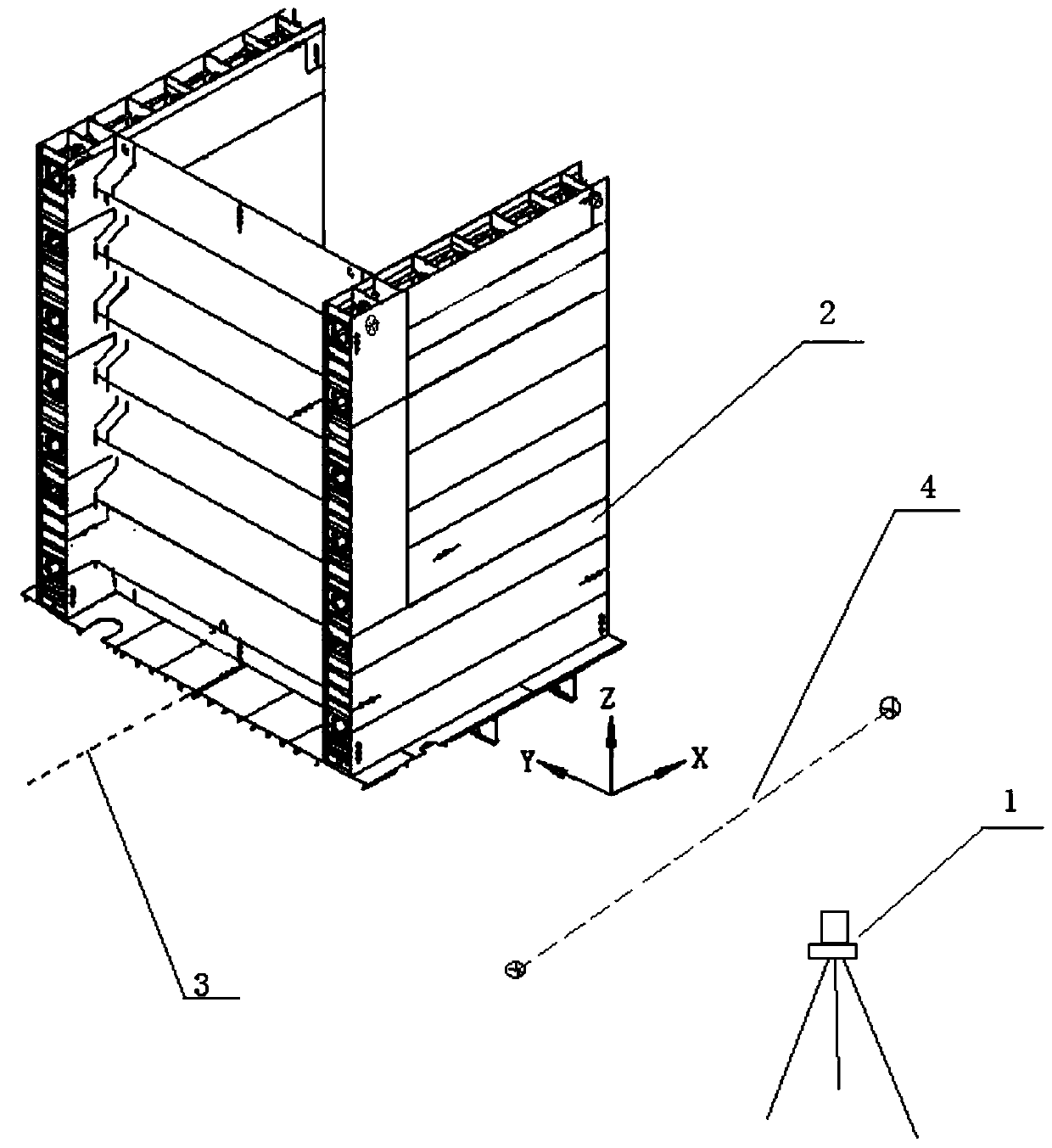

[0025] Such as figure 1 As shown, a method of using a total station to monitor the U-shaped width of a chemical tanker includes the following steps:

[0026] Step 1: Set up the total station; 1.1. Set up auxiliary center lines on the port side and starboard side of the U-shaped general section at a distance D from the center line, and post reflective sheets a1 on both ends of the auxiliary center line on the port side. , a3, reflectors a2, a4 at both ends of the bow and stern of the auxiliary center line on the starboard side; 1.2. b3, paste reflectors b2 and b4 on the bow and stern lower openings on the starboard side of the U-shaped general section; calculate the height difference and horizontal distance from the U-shaped lower opening reflectors b1 and b2 on the port side to the auxiliary center line of the port side, and the starboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com