A tree-cutting device and a tree-cutting method using the device

A technology for cutting trees and driving devices, applied in the field of tree cutting devices and tree cutting operations, can solve the problems of high operation risk, low construction efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

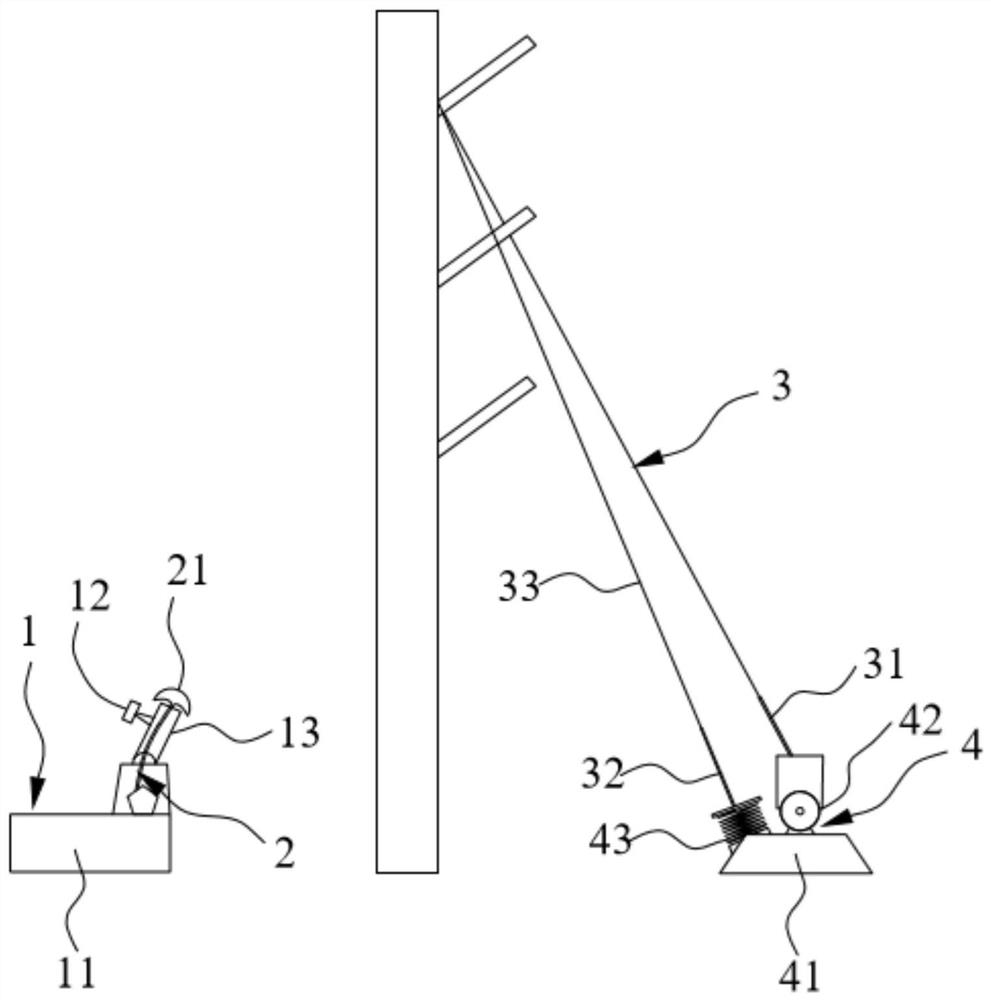

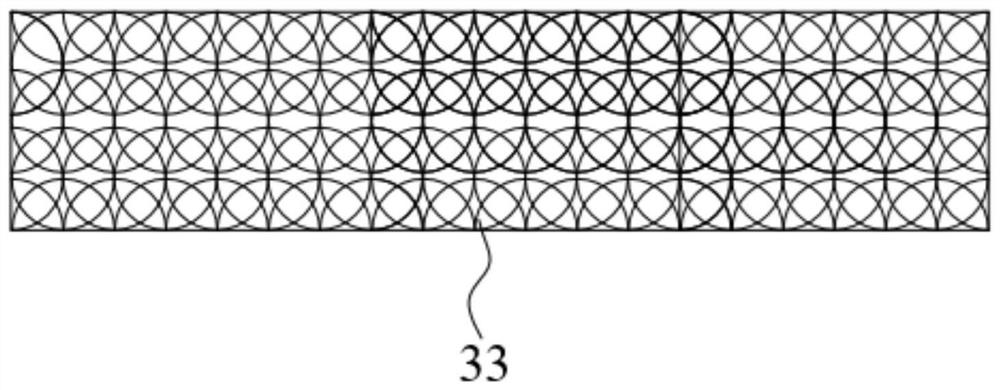

[0036] Such as Figure 1-2 As shown, the embodiment of the present invention provides a tree felling device, including a throwing device 1 , an insulating rope 2 , a metal cutting rope 3 and a driving device 4 . One end of the insulating rope 2 is fixed to the throwing device 1, and the other end is a free end. The free end is thrown into the air through the throwing device 1 and bypasses the branches to be felled; the insulating rope 2 can guide the metal cutting rope 3 to hang on the Above the branches; both ends of the metal cutting rope 3 hanging above the branches to be felled are fixed on the driving device 4, and the driving device 4 drives the metal cutting rope 3 to generate reciprocating motion, and the cutting is completed by reciprocating friction on the branches to be cut down.

[0037] Further, a pulling hammer 21 is fixed at the front end of the insulating rope 2 . The traction hammer 21 has a relatively large weight, which is convenient for the throwing device...

Embodiment 2

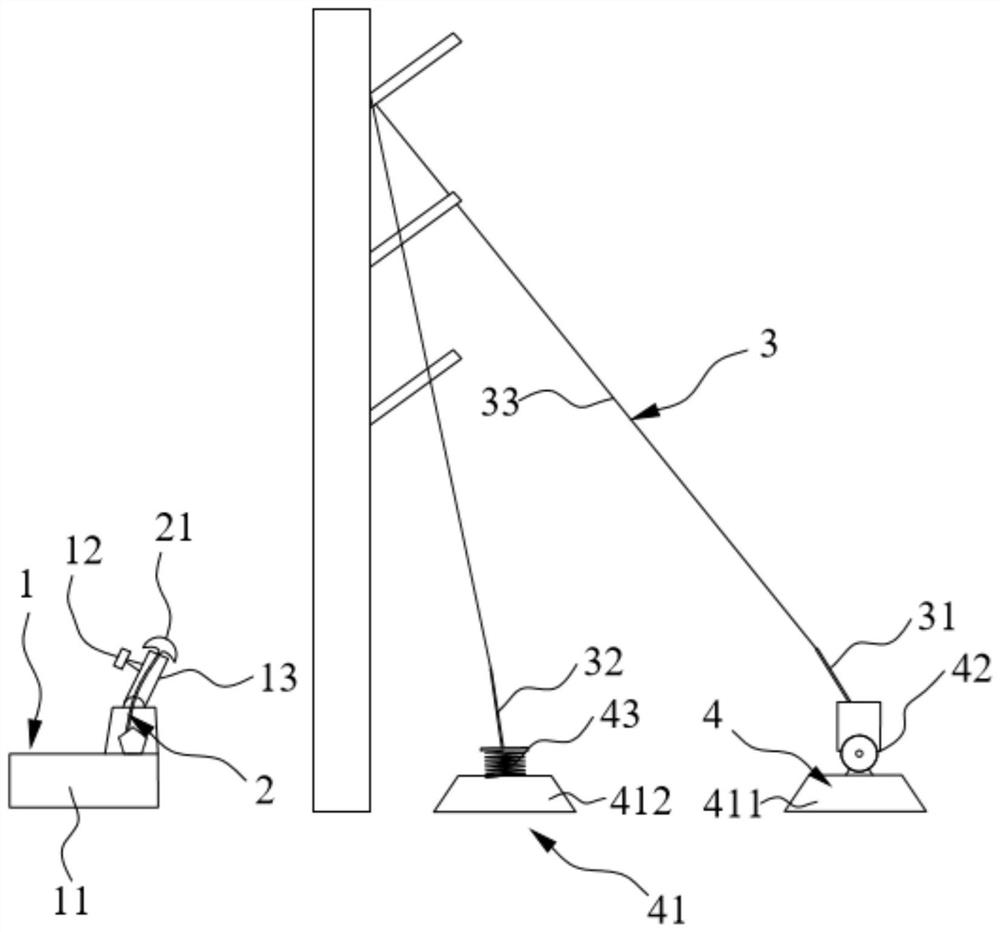

[0042] In the tree-cutting device provided by the present embodiment, its throwing device 1, insulating rope 2 and metal cutting rope 3 are the same as those in the first embodiment. The difference between this embodiment and Embodiment 1 is that the frame 41 of the driving device 4 includes a first frame 411 and a second frame 412, the power mechanism 42 is fixedly connected to the first frame 411, and the tension mechanism 43 is fixedly connected to The second rack 412 . The first frame 411 and the second frame 412 are set separately, so that the metal cutting rope 3 is at a certain angle on the branch to be felled, as image 3 shown. The included angle can be 0°-180°, and the specific implementation angle can be determined according to the terrain and the shape of the working tree, and is not limited to this embodiment. Preferably, universal wheels with a parking function may be installed on the bottoms of the first frame 411 and the second frame 412 to facilitate adjustm...

Embodiment 3

[0045] The embodiment of the present invention provides a kind of tree-cutting method, uses the tree-cutting device in embodiment 1 or embodiment 2, and its specific steps include:

[0046] Step S100, use the throwing device 1 to align the insulating rope 2 above the branch to be felled and throw it; wherein, one end of the insulating rope 2 is fixed to the throwing device 1, and the other end is a free end, and the free end is fixed with a traction hammer 21 ;

[0047] Step S200, after the insulating rope 2 bypasses the branch to be felled, connect one end of the insulating rope 2 to the metal cutting rope 3; this end can be the free end of the insulating rope 2, and the end of the insulating rope 2 with the traction hammer 21 can be used Connect the metal cutting rope 3; or this end can be the fixed end of the insulating rope 2, and the fixed end can be removed from the throwing device 1 and connected to the metal cutting rope 3;

[0048] Step S300, using the insulating rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com