Installing and fixing structure of voltage stabilizer for power system

A technology of power system and fixed structure, applied in substation/distribution device casing, substation/switchgear cooling/ventilation, electrical components, etc. Protective structure and other issues, to achieve the effect of easy installation and fixation, easy dustproof and heat dissipation, easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

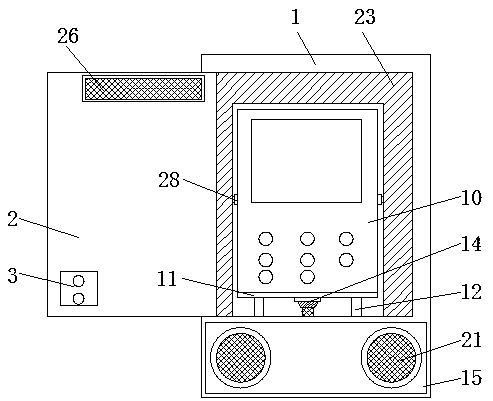

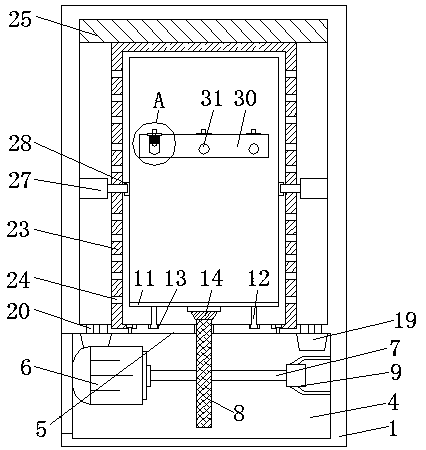

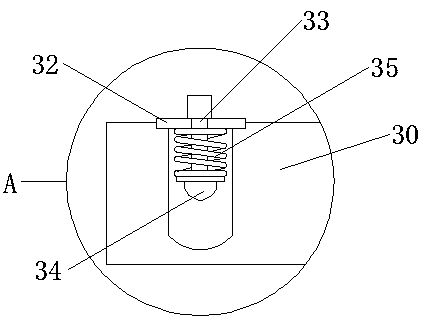

[0025] like Figure 1-6 As shown, an installation and fixing structure of a voltage stabilizer for a power system includes a cabinet for placing and installing the voltage stabilizer body, and the lower part of the cabinet is divided into an upper storage area and a lower accessory area by a horizontal plate. The front side of the cabinet body is provided with a cabinet door for opening and closing the storage area, the cabinet door is hinged with the cabinet body, the upper part of the cabinet door is provided with an air outlet, and a dust-proof net A is installed in the air outlet, and the lower part of the installation voltage stabilizer body A support plate is installed, and the lower part of the support plate is symmetrically arranged with a vertical slide plate, and the side of the horizontal plate is provided with a chute for accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com