Self-adapting extruding and shell breaking mechanism of ginkgo seed fresh fruit sheller

An adaptive, shelling machine technology, applied in the direction of shelling, application, pod removal, etc., can solve the problem of insufficient loading displacement of the extrusion mechanism, failure to meet the extrusion shell breaking deformation requirements, and inability to break shells and shelling rates And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] The invention provides a self-adaptive extrusion shell breaking mechanism for fresh ginkgo fruit shelling machine, which can carry out self-adaptive extrusion shell breaking for fresh ginkgo fruits with different sizes, so the shells are evenly broken and the shell breaking effect is good, especially suitable for Ginkgo and other fresh fruit shelling treatment.

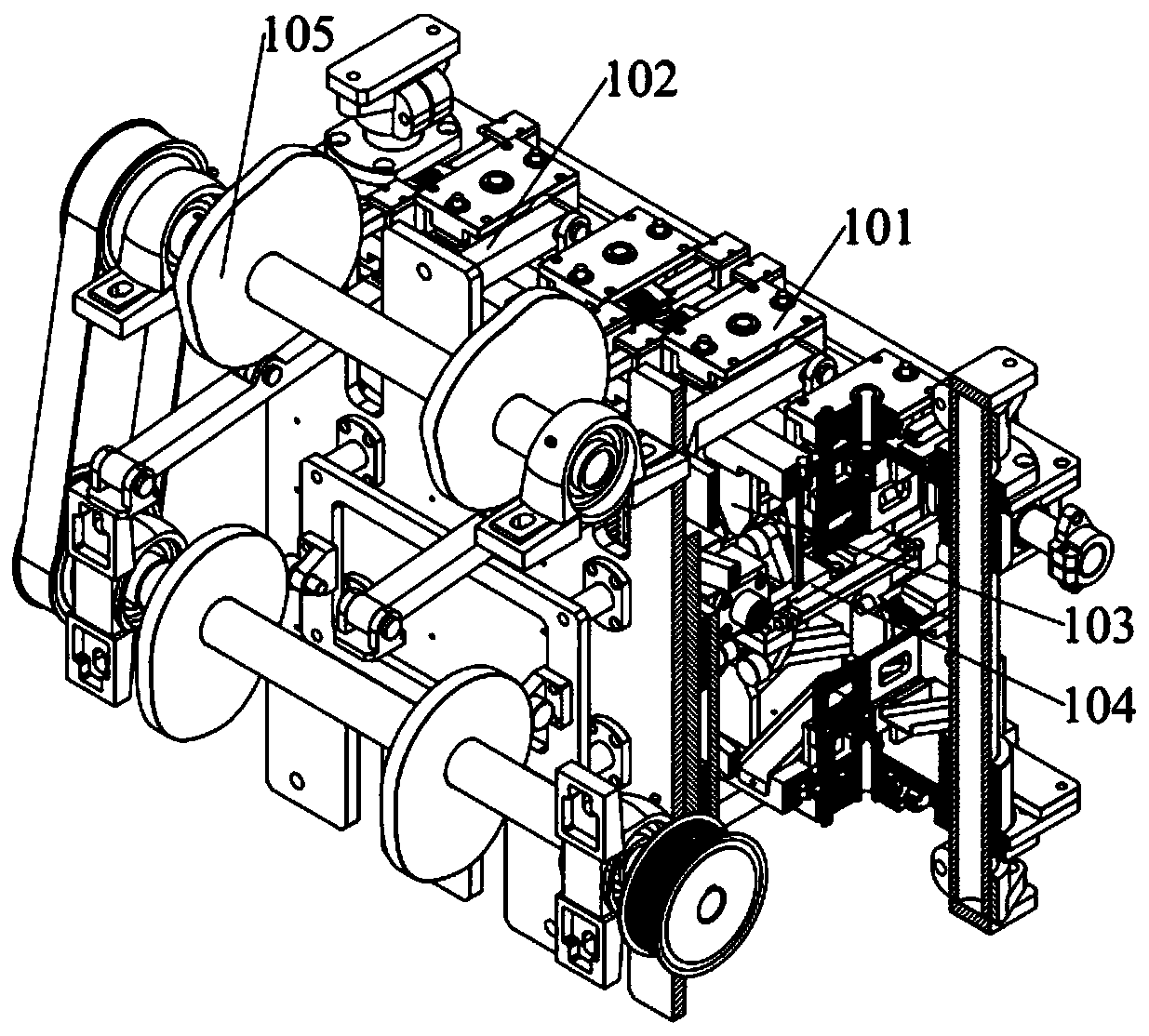

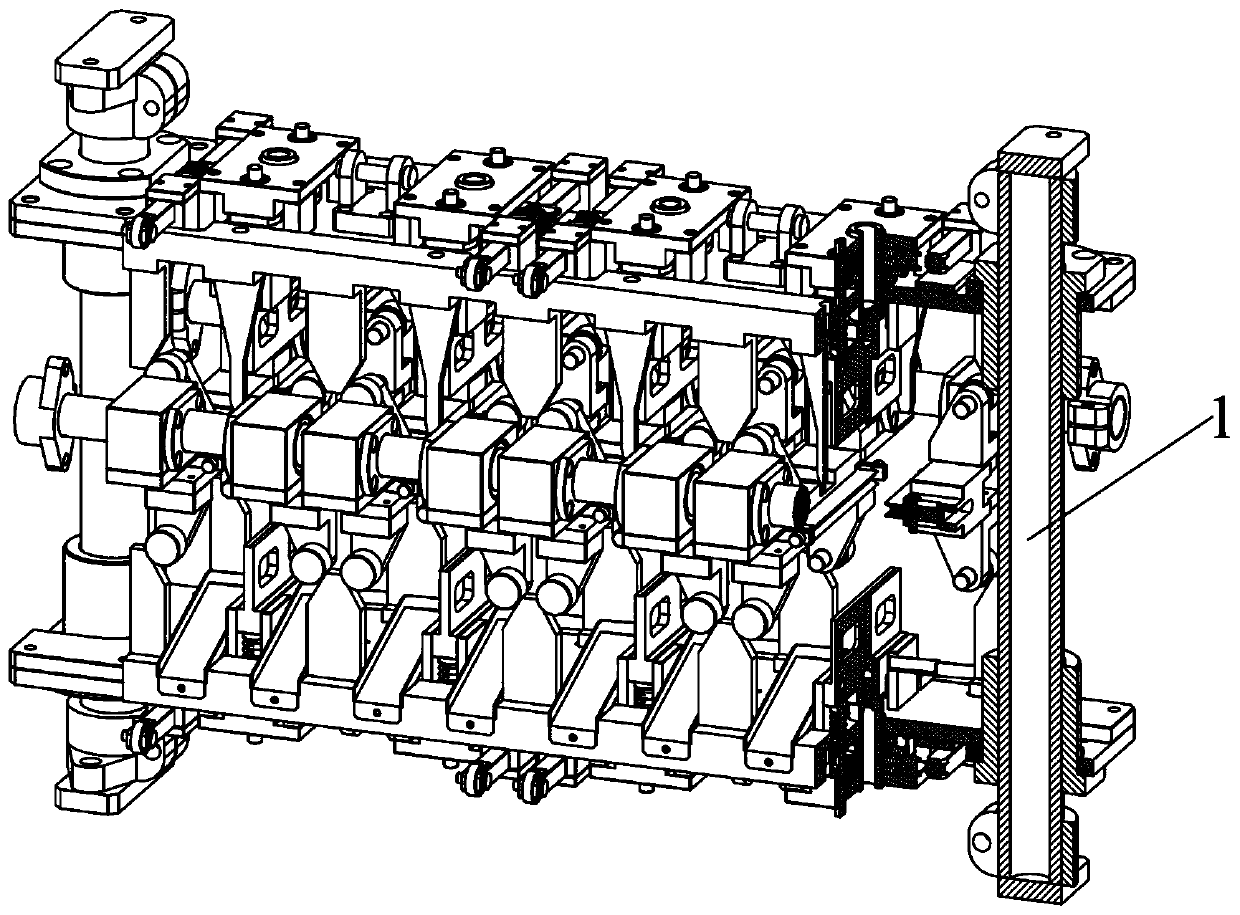

[0036] As an embodiment of the present invention, the present invention provides figure 1 and 2 The self-adaptive extrusion shell-breaking mechanism of a ginkgo fresh fruit sheller includes an adaptive extrusion knife tooth assembly 101, a synchronous motion control assembly 102, a clamping control fork assembly 103, and a clamping tooth assembly 104 and drive assembly 105;

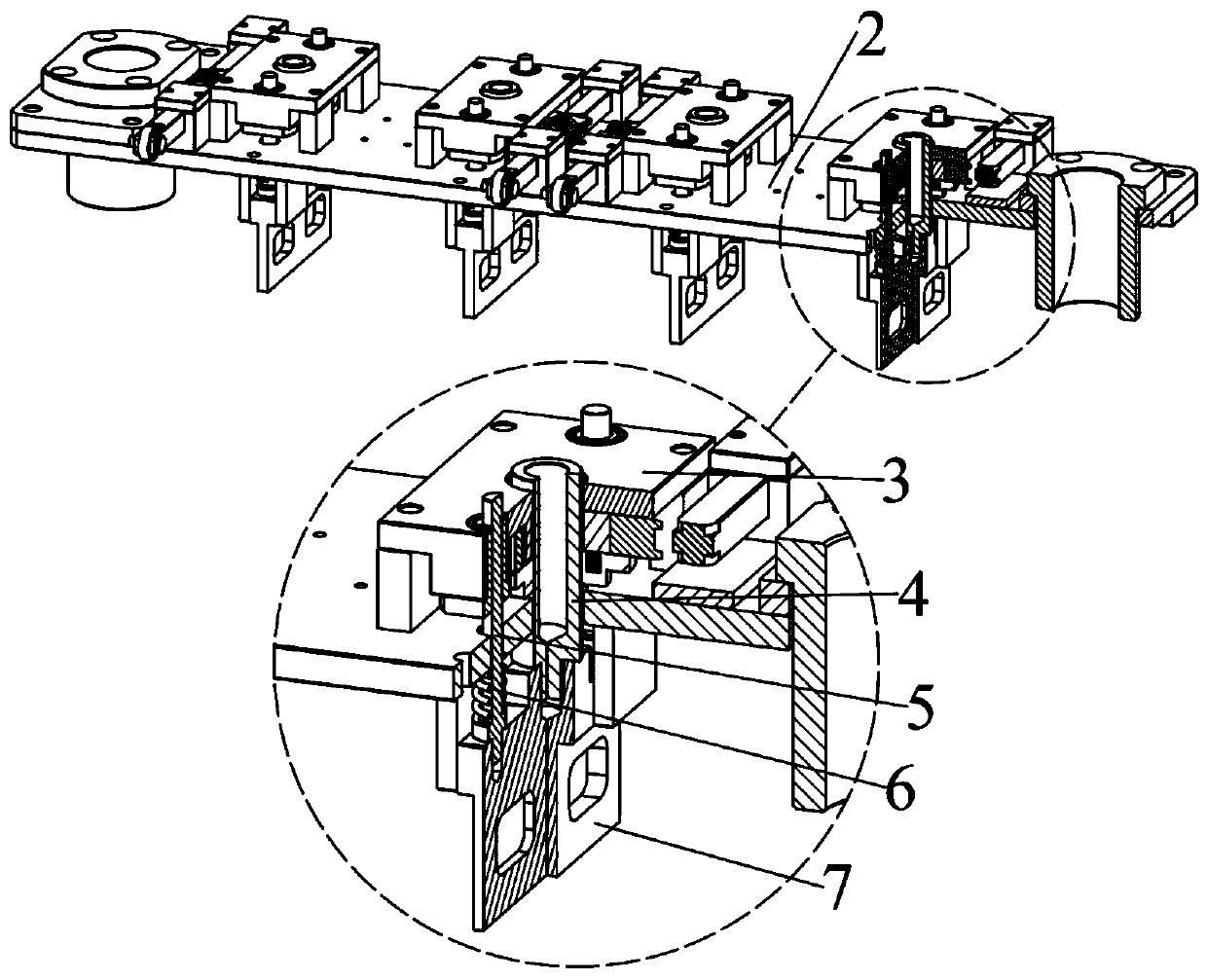

[0037] Adaptive extruded cutter unit such as Figure 4-7 Shown includes locker bottom plate 3, extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com