A laser processing method and device

A laser processing method and laser processing technology, which are applied to laser welding equipment, metal processing equipment, glass cutting devices, etc., can solve the problems of increasing raw material purchases, increasing production costs, and low yield, so as to save raw materials, increase profits, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

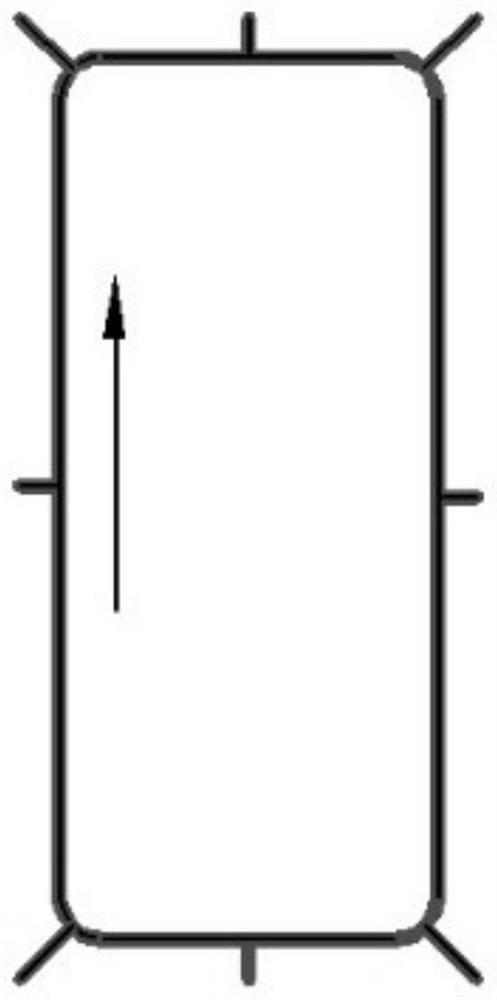

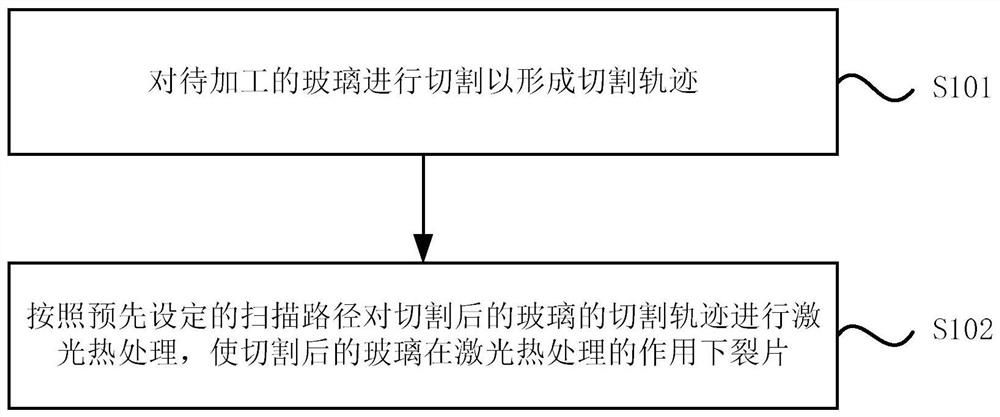

[0033] Please refer to the attached image 3 , the first embodiment provides a laser processing method, comprising steps:

[0034] S101 , cutting the glass to be processed to form a cutting track.

[0035] Trajectory cutting with an ultrafast laser.

[0036] S102 , performing laser heat treatment on the cutting track of the cut glass according to the preset scanning path, so that the cut glass is split under the action of the laser heat treatment.

[0037] Wherein, the laser used in the laser heat treatment of the glass is carbon dioxide laser.

[0038] It should be noted that when the laser heating splitting process is performed on the cut glass, the part of the surrounding remaining material that needs to be split is first irradiated with a carbon dioxide laser on the periphery, and then the inside of the glass is irradiated.

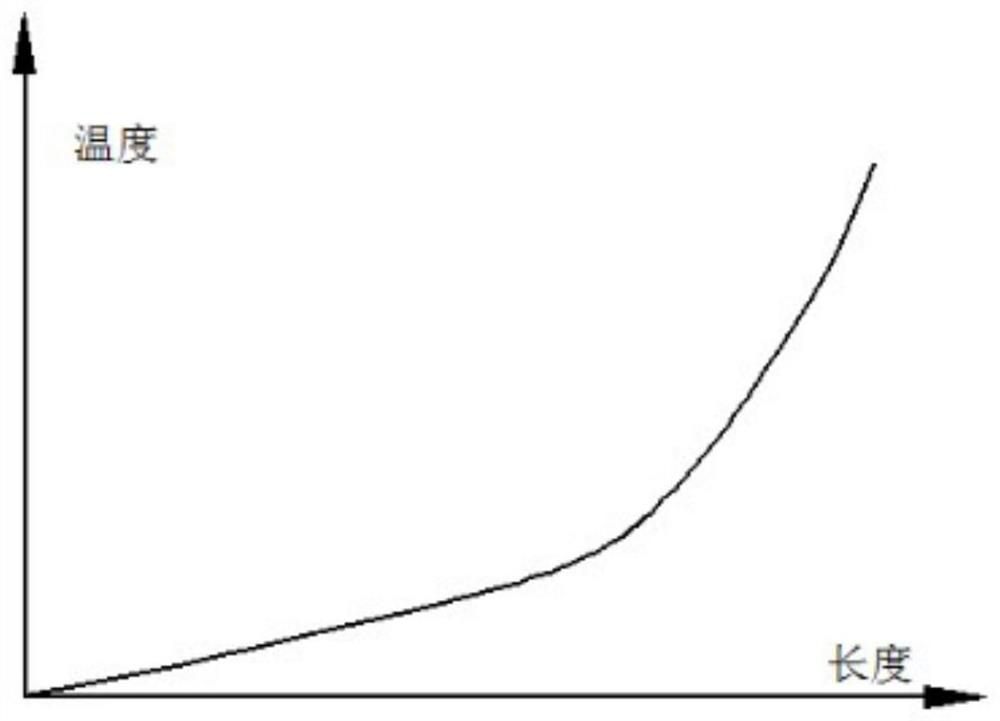

[0039] In one embodiment, preferably, the preset scanning path is a segmented and discontinuous jump scanning path. See Figure 4 , After heatin...

Embodiment 2

[0043] Such as Figure 5 As shown, Embodiment 2 of the present invention provides a laser processing method, which is further optimized on the basis of the technical solution provided in Embodiment 1. Explanations of terms that are the same as or corresponding to the above embodiments are not repeated here. Specifically include the following steps:

[0044] S201. Cut the glass to be processed to form a cutting track.

[0045] S202 , performing laser heat treatment on the cutting track of the cut glass according to the preset scanning path, so that the cut glass is split under the action of the laser heat treatment.

[0046] S203 , polishing and grinding the cut surface of the split glass, and grinding an arc chamfer.

[0047] Wherein, the grinding time of each glass is 6-8 seconds / piece.

[0048] Specifically, the glass sheet is placed on the receiving table of the glass grinding device, and then the cutting surface of the glass sheet is polished and ground by the grinding...

Embodiment 3

[0051] Such as Image 6 As shown, Embodiment 3 of the present invention provides a laser processing device, which specifically includes the following modules:

[0052] The carrier 31 is used to carry and transport the glass to be processed;

[0053] The cutting module 32 is arranged at the front end of the carrier 61 in the conveying direction and above the glass, for cutting the glass to form a cutting track;

[0054] The laser heating module 33 is arranged at the rear end of the cutting device 62, and is used to generate laser light, and perform laser heat treatment on the cutting track of the cut glass according to the preset scanning path, so that the cut glass can be heated during the laser heat treatment. The lobes under action.

[0055] Preferably, the preset scanning path is a jump scanning path with discontinuous segments.

[0056]Preferably, the laser used in the laser heat treatment of the glass is carbon dioxide laser.

[0057] Preferably, the laser processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com