Crushing cavity wear monitoring method

A crushing cavity and wear rate technology, applied in testing/monitoring control systems, instruments, control/regulating systems, etc., can solve the problems of inability to monitor and detect local area features, high wear rates, and high operating costs of crushers, reducing The effect of crusher failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] A service node for monitoring a crushing chamber comprising:

[0092] Calculation equipment for calculating the measured liner thickness at each detection node at different positions in the crushing cavity;

[0093] The computing device includes a host computer and an ultrasonic ranging and transmission module, and the host computer is connected to the ultrasonic ranging sensor in the detection node through the ultrasonic ranging and transmitting module.

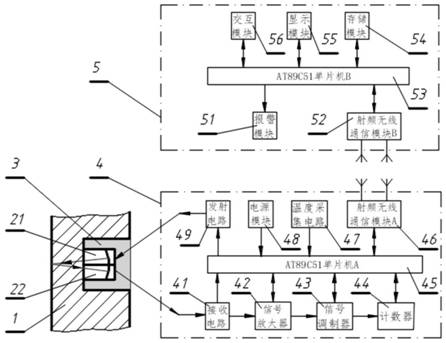

[0094] The ultrasonic ranging and transmission module 4 includes a first single-chip microcomputer 45 and a first radio frequency wireless communication module 46, and the host computer 5 includes a second single-chip microcomputer 53 and a second radio frequency wireless communication module 52, and the first single-chip microcomputer 45 and the first radio frequency wireless communication module 52 The second single-chip microcomputer 53 performs wireless communication through the first radio frequency wireless comm...

Embodiment 2

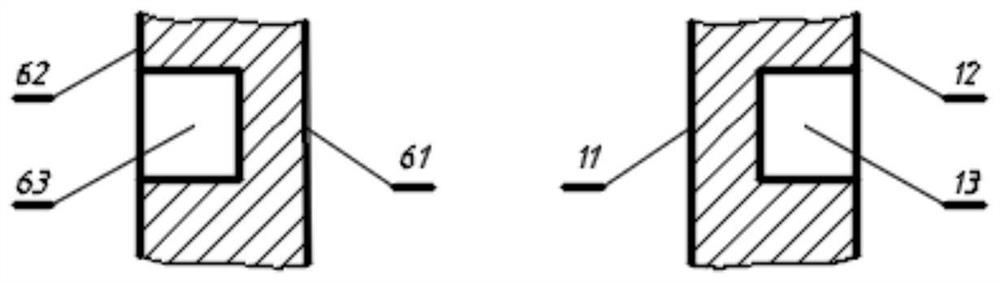

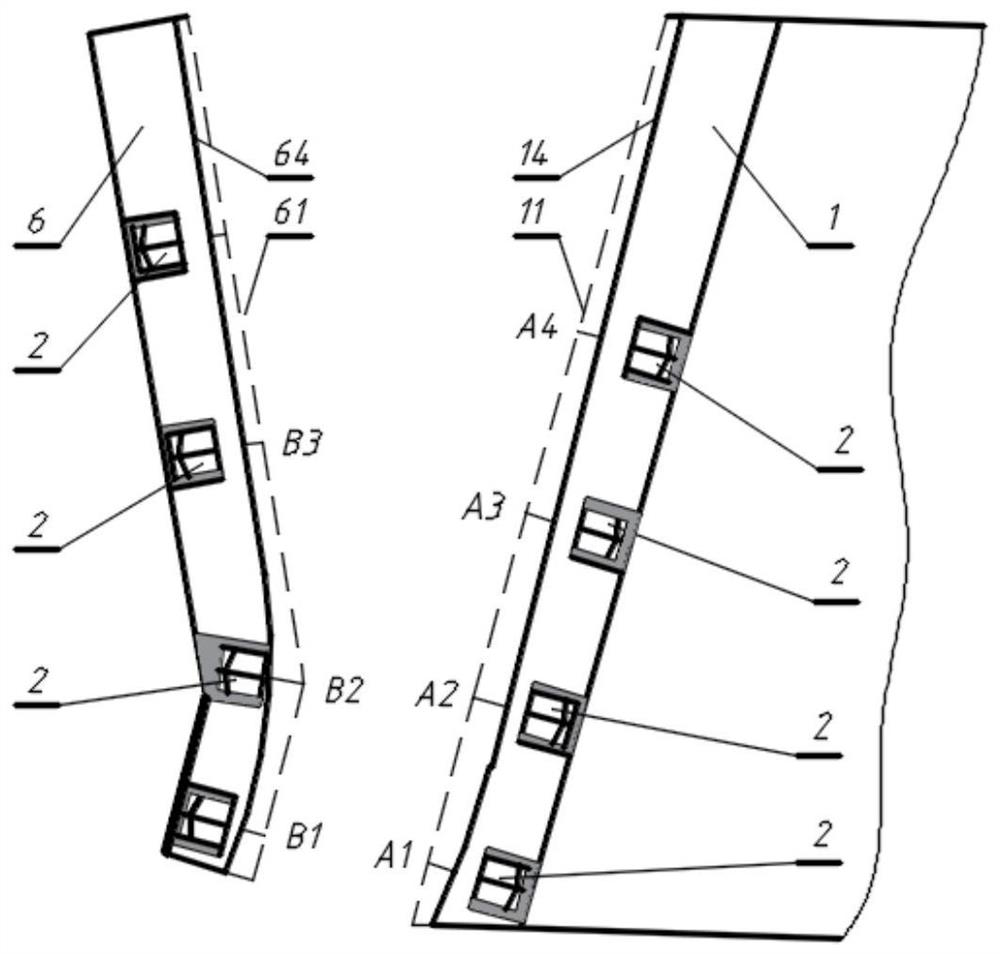

[0117] Based on Example 1, such as figure 1 As shown, the present invention discloses an intelligent liner, including a movable cone liner 1 , a fixed cone liner 6 , an ultrasonic ranging sensor 2 , a coupling agent 3 , an ultrasonic ranging and transmission module 4 and a host computer 5 . The ultrasonic ranging sensor 2 is composed of a transmitting chip 21 and a receiving chip 22. The ultrasonic ranging sensor 2 is installed in the blind hole 13 on the side of the non-working surface of the lining plate 1, and in the blind hole 1 of the lining plate 1 13 is filled with coupling agent 3 between the ultrasonic distance measuring sensor 2, the transmitting chip 21 of the ultrasonic ranging sensor 2 is connected with the transmitting circuit 49 of the ultrasonic ranging and transmission module 4, and the ultrasonic ranging sensor 2 The receiving chip 22 is connected to the receiving circuit 41 of the ultrasonic ranging and transmission module 4, and the host computer 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com