Automatic tray warehouse and transfer method thereof

A pallet warehouse and pallet technology, applied in the directions of transportation and packaging, object stacking, object destacking, etc., can solve problems such as potential safety hazards, achieve high efficiency and reduce manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

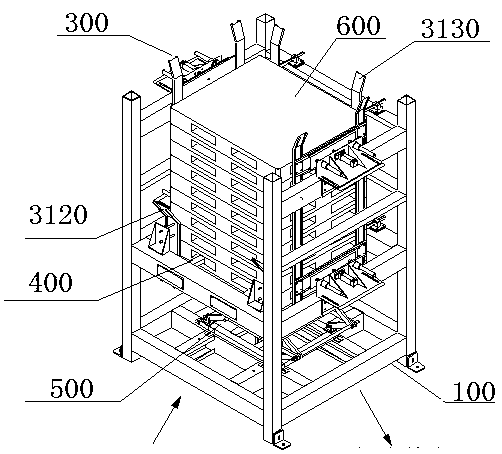

[0031] Such as Figure 1-8 As shown, an automatic pallet warehouse includes a frame 100, a pallet seat 200 for stacking pallets 600 is provided in the middle of the frame, and a centering mechanism 300 is respectively provided on the left and right sides of the tray seat on the upper part of the frame. A pair of support mechanisms 400 for supporting the trays are respectively provided on the front and rear sides of the frame, and a lifting mechanism 500 is provided at the bottom of the tray base to drive the tray base up and down.

[0032] Specifically, the frame 100 is included, and the frame 100 has a tray seat 200 for stacking trays in the middle, and the tray seat 200 is driven up and down by a lifting mechanism;

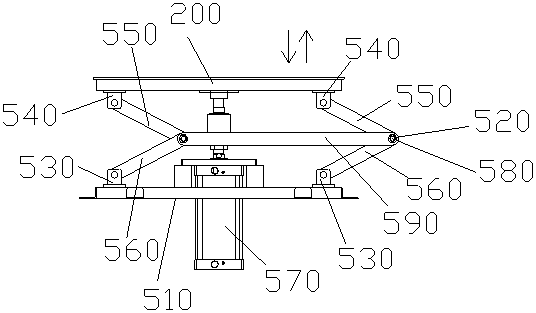

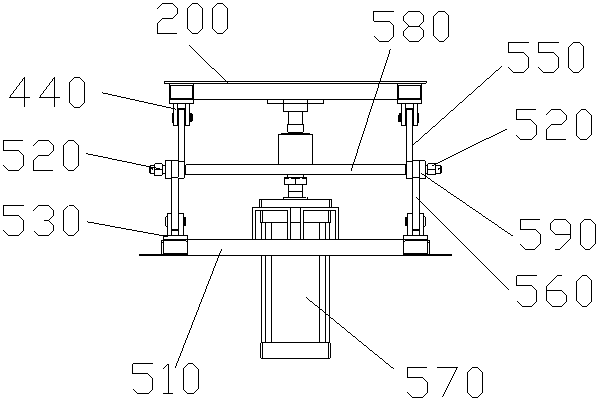

[0033] The lifting mechanism 500 includes a base support 510 located at the bottom of the tray base 200, the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com