Floating slab limiting device and floating track bed

A technology of a limit device and a floating plate, which is applied in the field of rail transit, can solve the problems of hard collision, reduce the effect of vibration reduction, and pull out upward, so as to reduce hard collision and friction, avoid the effect of vibration reduction, and avoid pulling upward out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present disclosure will be further described in detail below with reference to the drawings and embodiments. The following examples are used to illustrate the present disclosure, but not to limit the scope of the present disclosure.

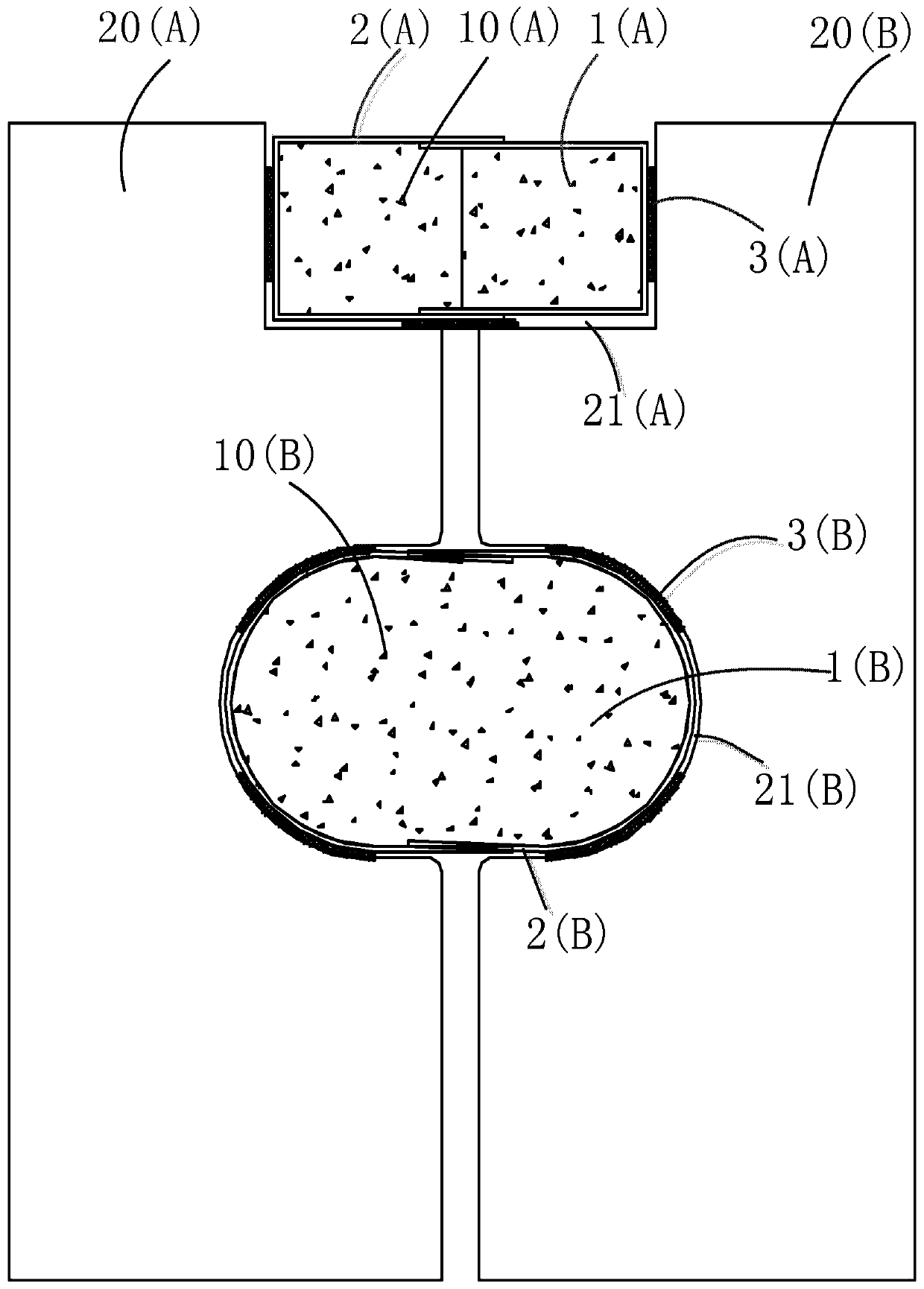

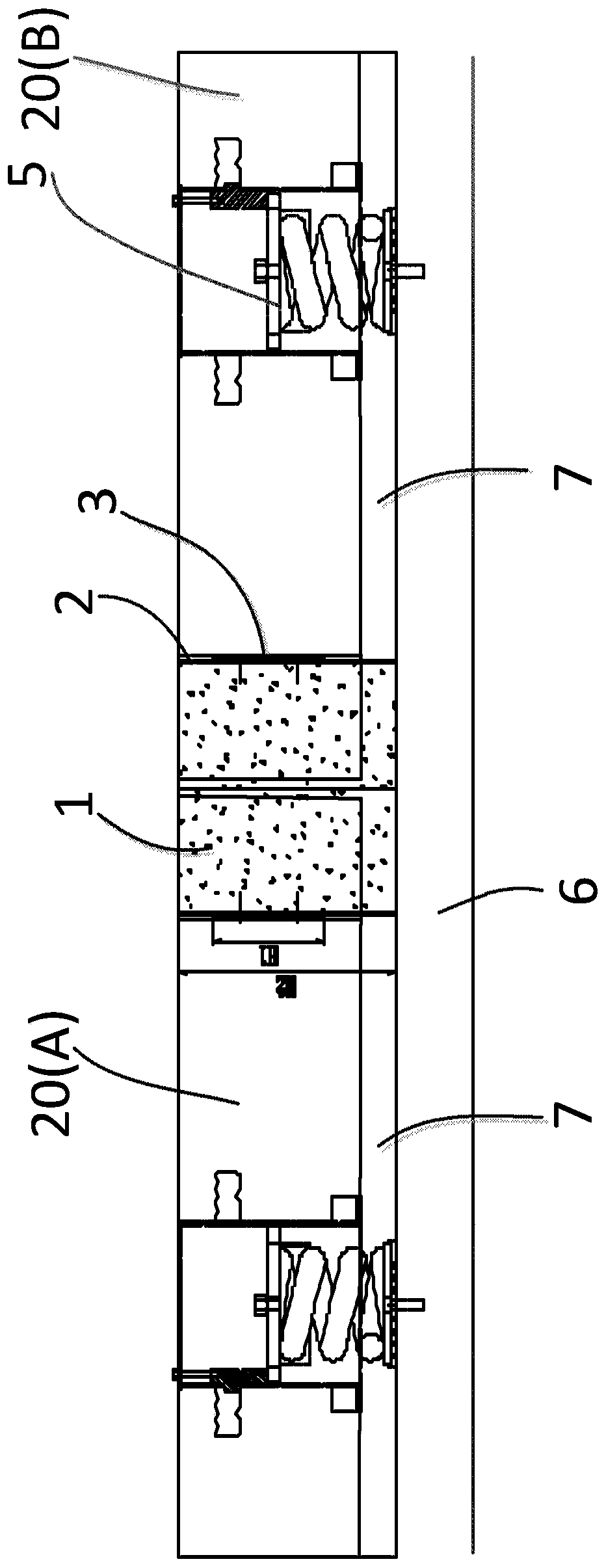

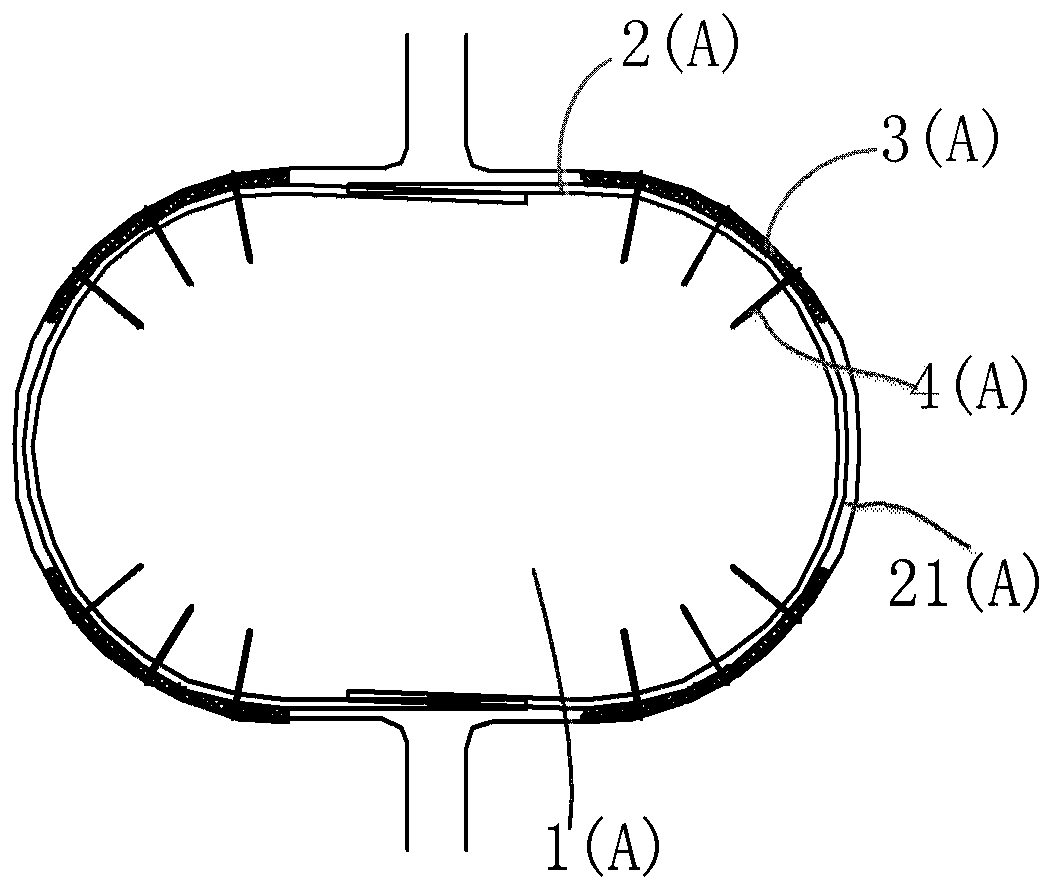

[0024] figure 1 A preferred embodiment of a floating plate limiting device according to the present disclosure is shown. As shown in the figure, the floating slab limiting device 10 includes a concrete limiting block arranged in the notch 21 of the floating slab 20 , and the shape of the concrete limiting stopper is substantially the same as that of the notch 21 . Between the concrete limit block and the floating plate 20, there is a buffer pad assembly which is anchored to the concrete limit block. The rigid plate 8 (such as Figure 4 shown), wherein, the material of the cushion body 3 can be rubber or other polymer materials, and its technical indicators should meet the relevant design requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com