Asphalt crack pouring device for cement road paving

A road and asphalt technology, which is applied in the field of asphalt joint filling devices for paving cement roads, can solve the problems of time-consuming, time-consuming and labor-intensive projects, and shorten the construction period, etc., and achieve the effects of centralized and simple procedures, improved work efficiency, and fast and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

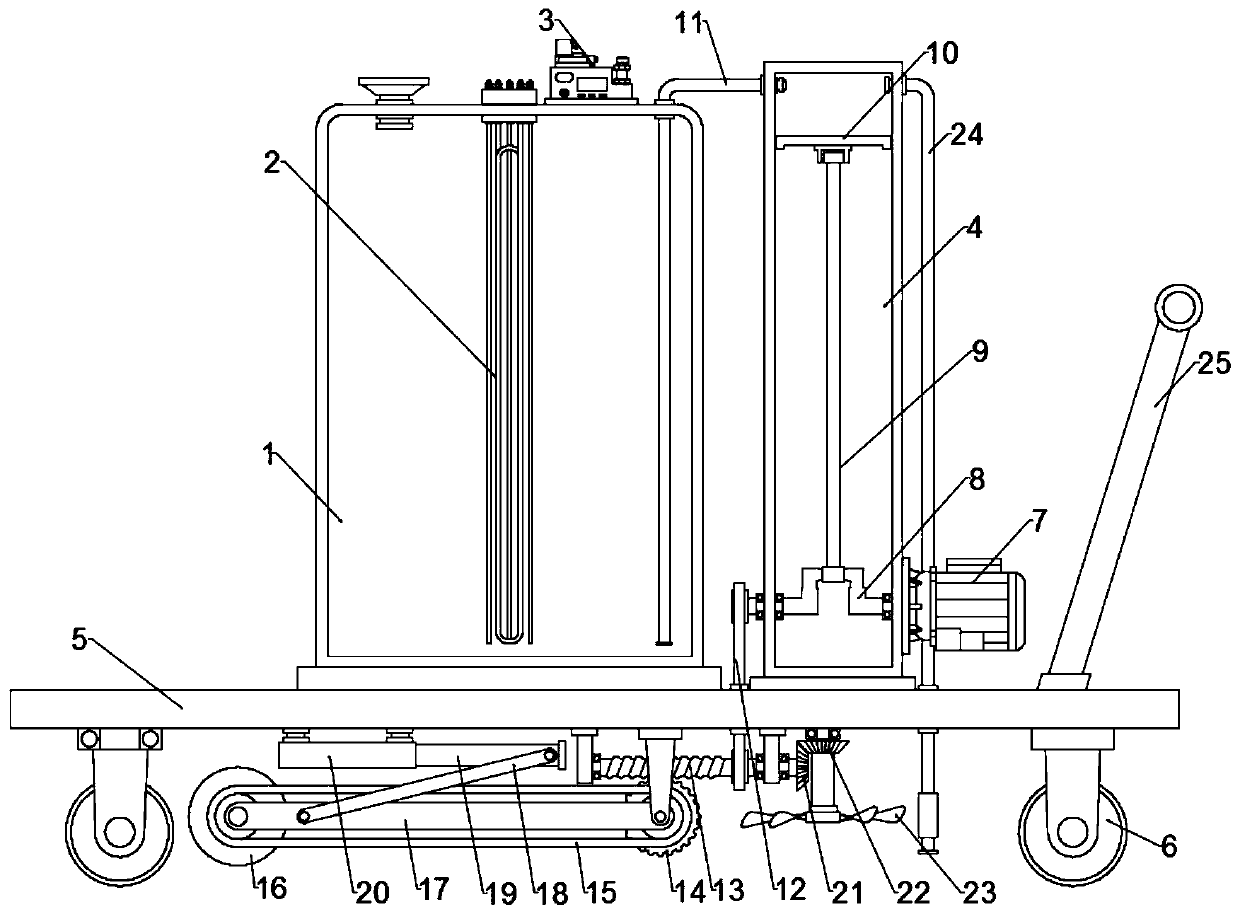

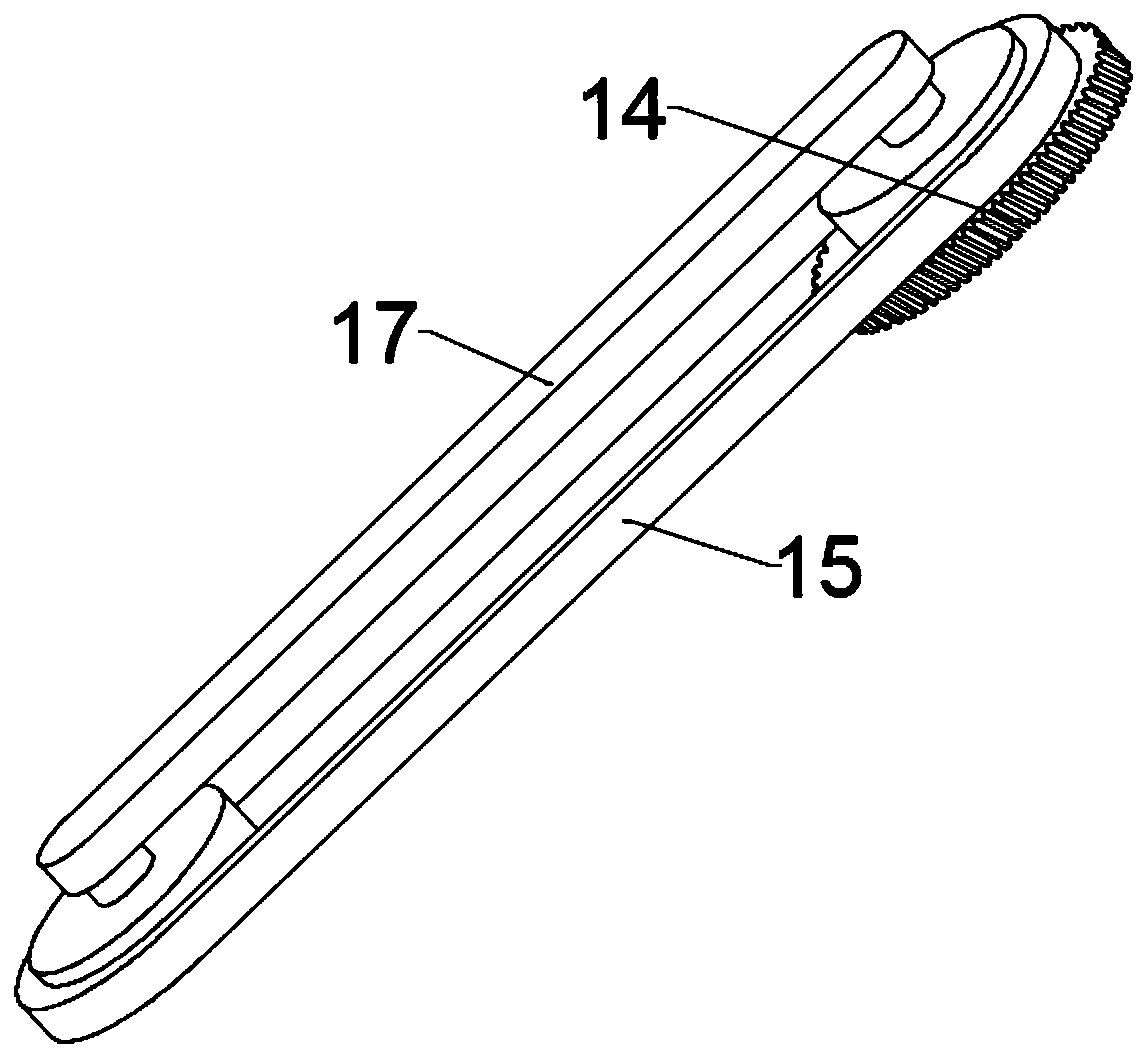

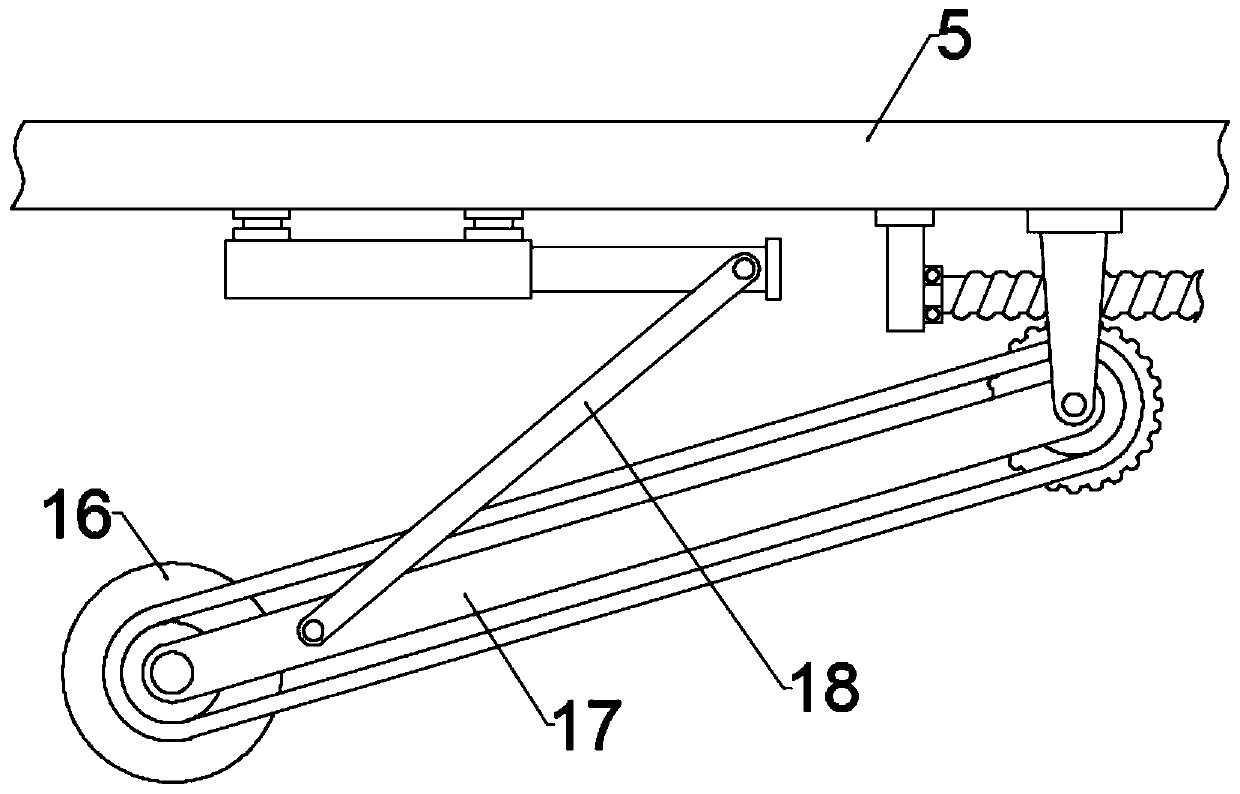

[0022] see Figure 1~3 , in an embodiment of the present invention, an asphalt joint filling device for paving cement roads, comprising a heating barrel 1 fixed on a bottom plate 5, a liquid pumping tank 4 positioned on one side of the heating barrel 1, and a cutting tool for slit cement road surface Components; wherein, a hopper for injecting asphalt is fixed through the top of the heating barrel 1, and an electric heater 2 with a signal connection controller 3 and a power supply is fixed inside the heating barrel 1, and the heating barrel 1 and the pumping tank 4 pass through The liquid pipe 11 is connected, and a one-way valve is arranged at the upper mouth of the liquid inlet pipe 11, and the upper part of the liquid pumping tank 4 is connected to and fixed on the liquid outlet pipe 24, and the asphalt in the heating barrel 1 is heated by the electric heater 2 , keep it in a flowing liquid state, and utilize the pumping tank 4 to pour the asphalt in the heating barrel 1 in...

Embodiment 2

[0027] Obviously, there will inevitably be dust on the ground seam cut out, therefore, in order to pour asphalt into the ground seam better, a blower assembly is also provided under the bottom plate 5, specifically, the blower assembly includes The bevel gear set at the end, the bevel gear set is composed of the first bevel gear 21 fixed on the end of the worm 13 and the second bevel gear 22 fixed on the rotating shaft, the first bevel gear 21 meshes with the second bevel gear 22, and the rotating shaft The upper end is rotatably connected to the bottom plate 1, and the lower end of the rotating shaft is fixed with a fan blade 23. The rotating worm 13 drives the rotating shaft to rotate through the bevel gear set, thereby realizing the driving of the fan blade 23 to rotate and blow air, and achieve the integrated function of cutting, blowing, and filling seams;

[0028] The lower corners of the base plate 5 are all rotatably provided with rollers 6, and the top of the rear port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com