Waterproof press-riveting nut for hardware

A technology for pressing riveting nuts and hardware parts, applied in the field of nuts and riveting nuts, can solve the problems of insufficient tight connection and poor waterproof performance, and achieve the effect of improving the tightness of the connection and improving the waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

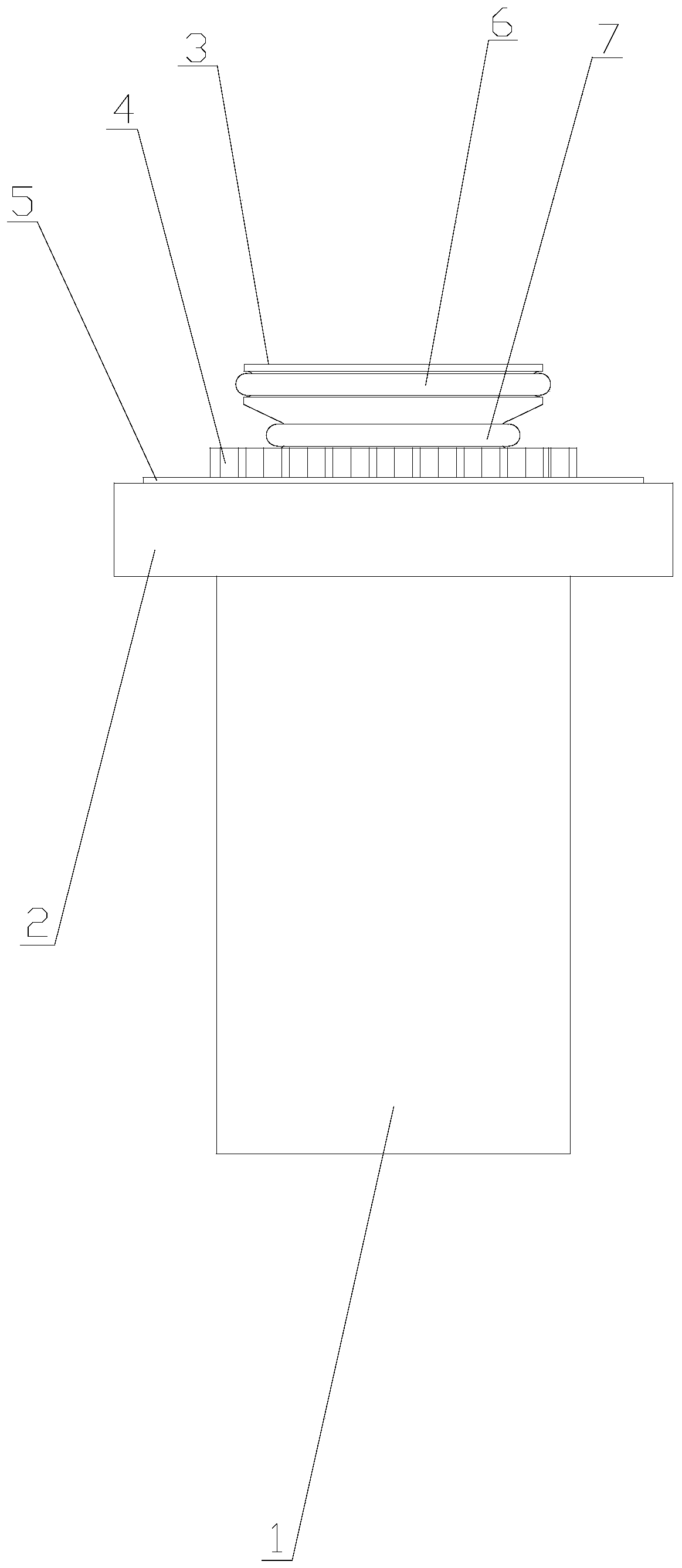

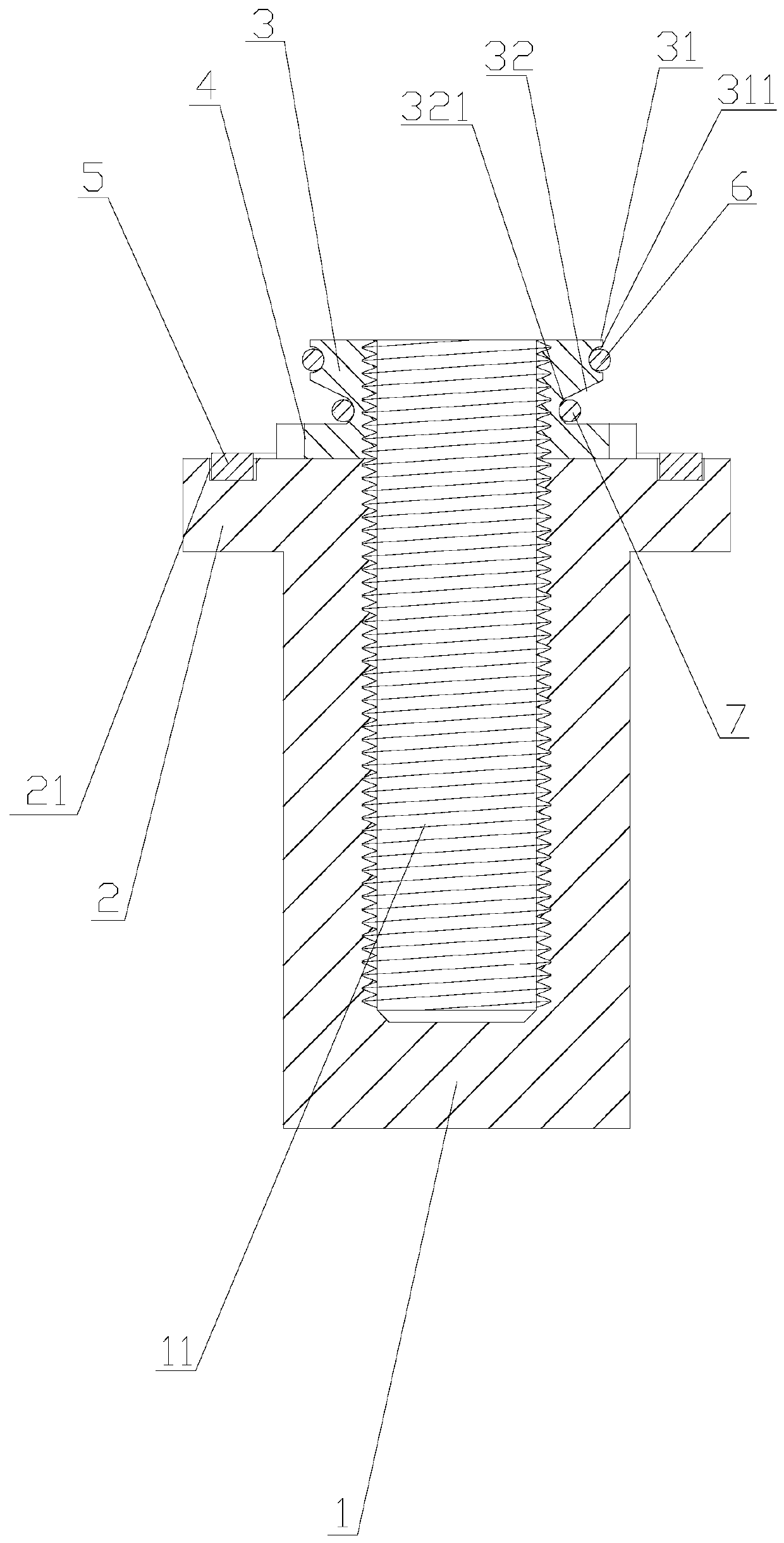

[0021] refer to figure 1 with figure 2 , a waterproof press riveting nut for hardware according to the present invention, comprising a nut body 1, a limiting platform 2, a deformation compression structure 3, positioning teeth 4, and a first annular sealing ring 5, the nut body 1 is cylindrical, The center of the nut body 1 is provided with a threaded cavity 11, the threaded cavity 11 is a structure with an open upper end and a closed lower end, the upper end of the nut body 1 is provided with a limiting platform 2, and the limiting platform 2 is a disc shape, the upper end of the limiting platform 2 compresses the structure 3, and a number of positioning teeth 4 are uniformly arranged between the pressing structure 3 and the limiting platform 2, and the positioning teeth 4 wrap around the lower end of the limiting platform 2, etc. The opening end of the threaded cavity 11 runs through the limiting platform 2 and the deformation compression structure 3, and the upper end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com