Submarine cable armoring wire crevice corrosion test device and evaluation method

A crevice corrosion and submarine cable armor technology, applied in the field of metal material crevice corrosion testing, can solve the deterioration of armor wire corrosion, lack of targeted crevice corrosion evaluation tools or methods, and it is difficult to scientifically reflect the sea cable armor wire crevice corrosion. Regularity and corrosion electrochemical parameters, etc., to achieve the effect of convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings.

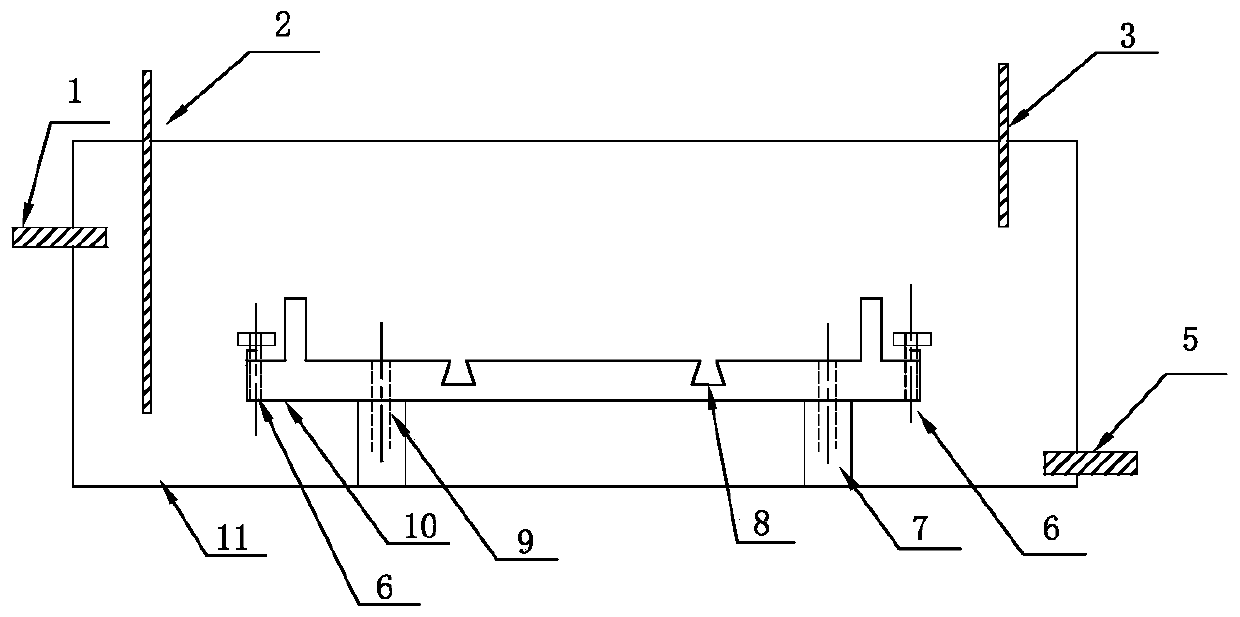

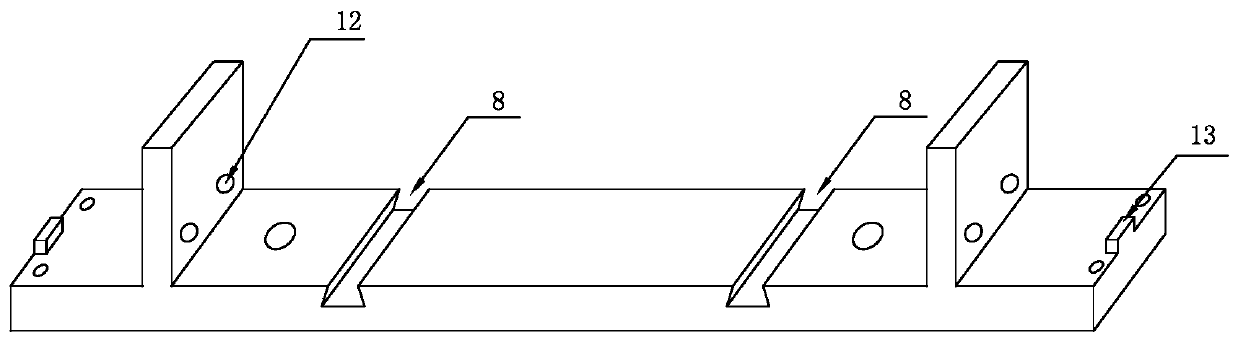

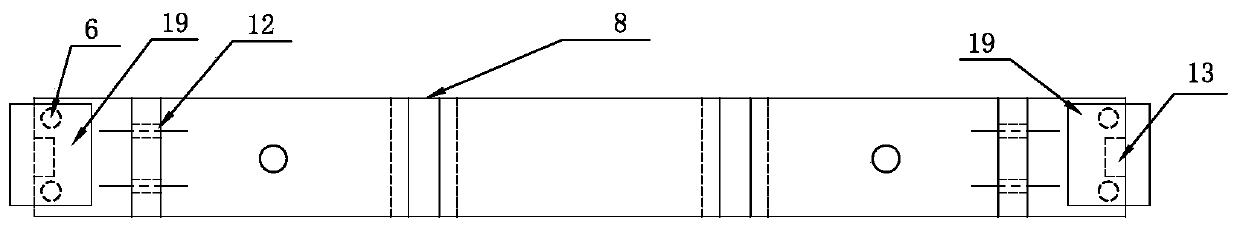

[0036] see Figure 1-8 , the present invention proposes a device for sea cable armored wire material crevice corrosion test, which consists of a liquid inlet pipe 1, an air inlet pipe 2, an exhaust pipe 3, a liquid discharge pipe 5, a pressing plate fastening screw 6, a fixing seat 7, Longitudinal positioning groove 8, fixture fixing bolt 9, crevice corrosion fixture 10, seawater medium test box 11, support limit hole 12, boss 13, clamp block 14, screw rod and nut 15, platinum wire electrode 16, Ag / AgCl reference An electrode 17, an electrochemical workstation 18 and a pressing plate 19 are formed. Wherein, the seawater medium tank 11 is equipped with a fixed seat 7, and the crevice corrosion fixture 10 that has assembled the wire mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com