Two-procedure machining dynamic scheduling method of fault-free RGV intelligent system

An intelligent system and dynamic scheduling technology, applied in the field of RGV, can solve the problems of small and medium-sized enterprises such as unobvious practicability, lack of distribution scheme, and low utilization efficiency of RGV intelligent system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

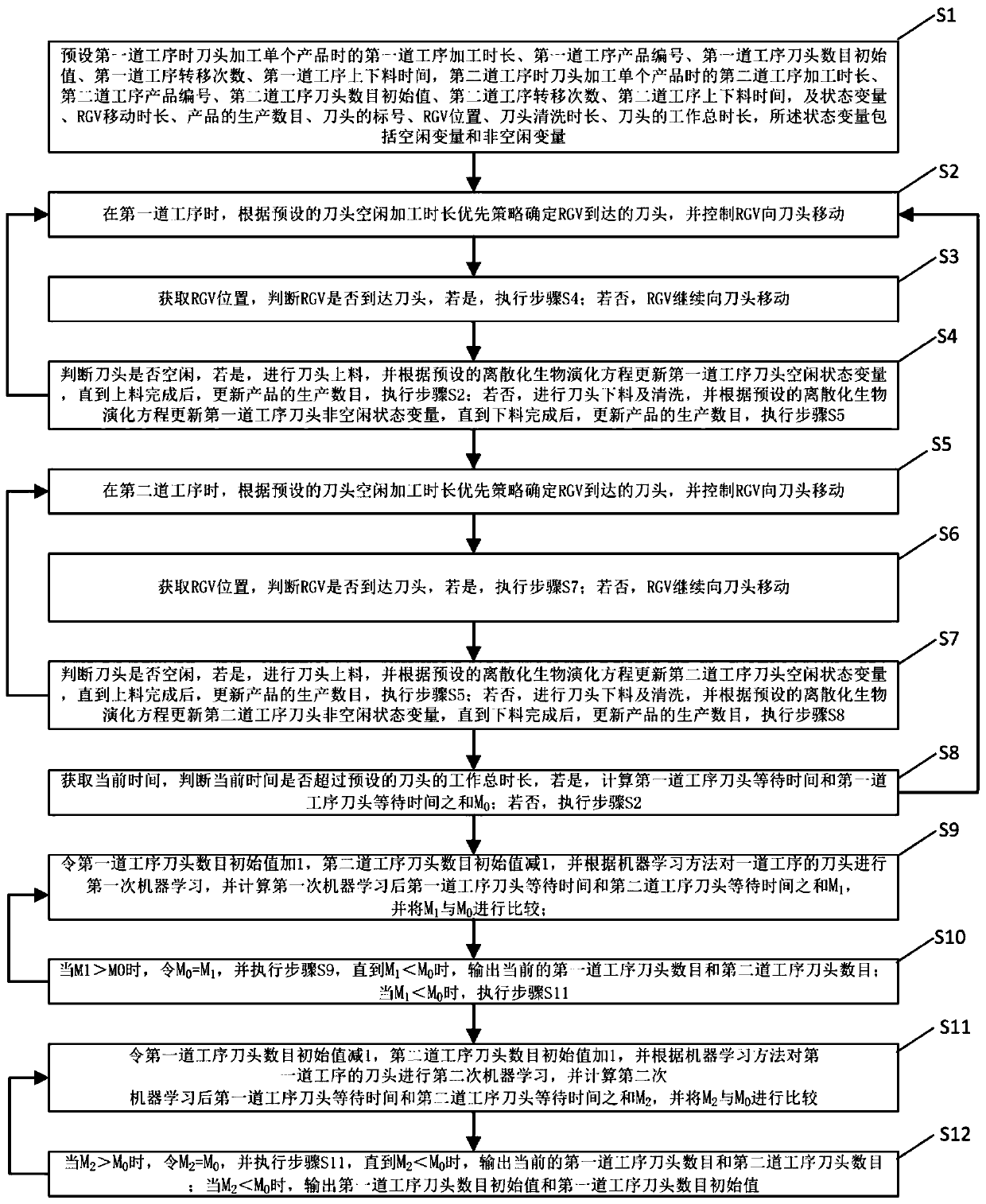

[0046] refer to figure 1, a kind of trouble-free RGV intelligent system two process processing dynamic scheduling method proposed by the present invention, comprising:

[0047] Step S1, preset the processing time of the first process when the cutter head processes a single product in the first process, the product number of the first process, the initial value of the number of cutter heads in the first process, the transfer times of the first process, the first The loading and unloading time of the first process, the processing time of the second process when the cutter head processes a single product in the second process, the product number of the second process, the initial value of the number of cutter heads in the second process, the transfer times of the second process, and the second process The loading and unloading time of the second process, and state variables, RGV moving time, product production quantity, cutter head label, RGV position, cutter head cleaning time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com