A permeable membrane preparation device

A technology for preparing devices and permeable membranes, which is applied in the field of thin film permeability testing, can solve the problems of inconvenient testing, permeable membrane folds, folding, etc., and achieve the effects of improved accuracy, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The first film-forming surface is located at the outer edge of the second film-forming surface

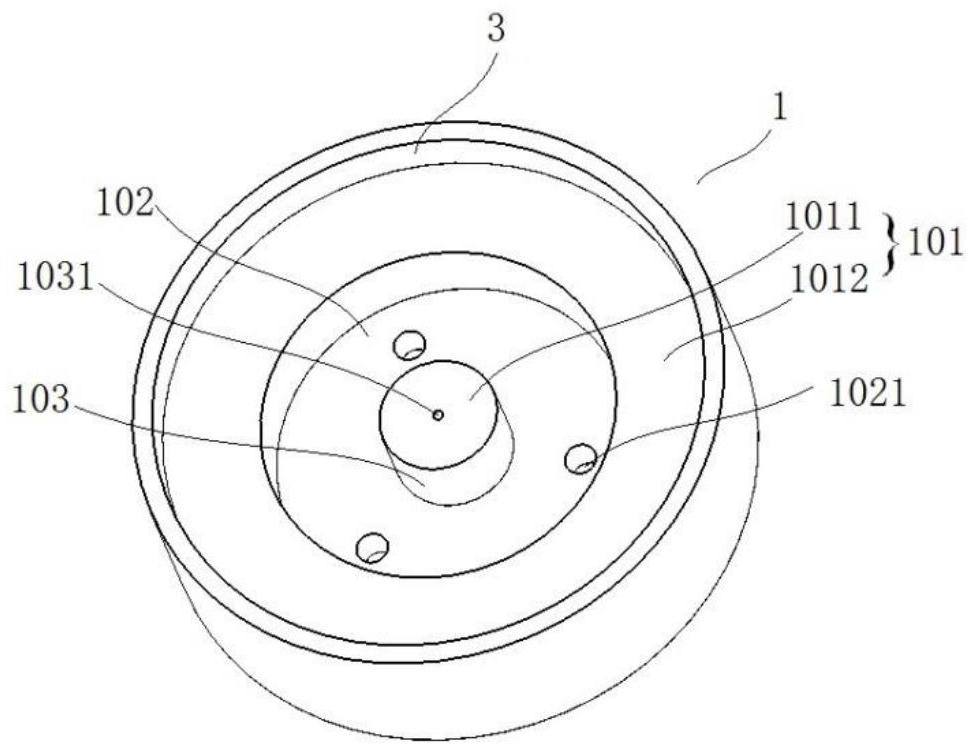

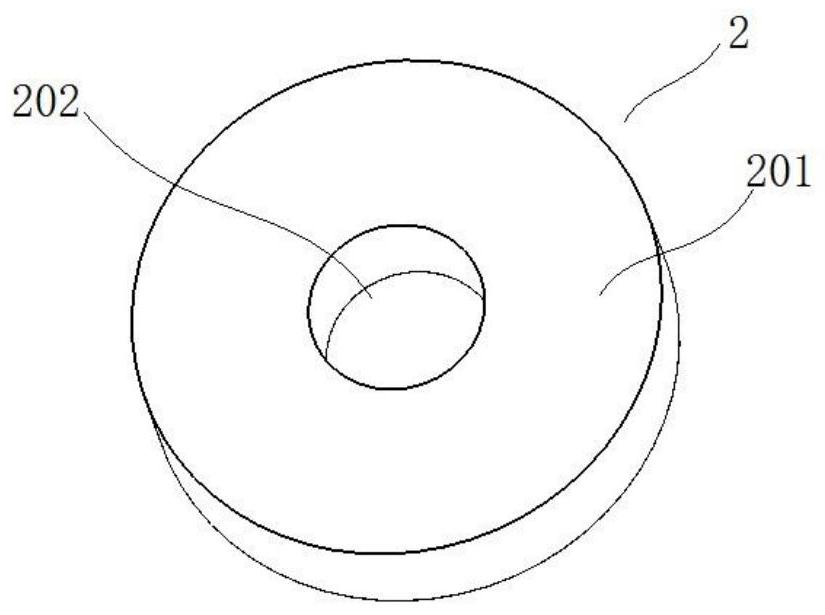

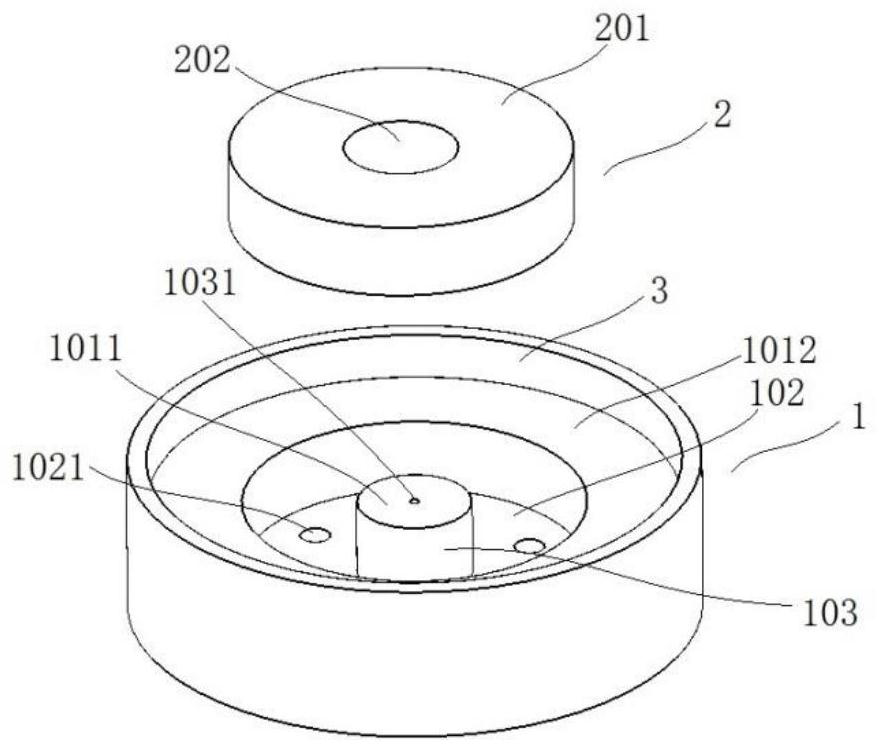

[0046] When the tray 1 is combined with the film forming plate 2 , the first film forming surface 101 is located at the outer edge of the second film forming surface 201 . The tray 1 has a groove 102 for accommodating the film forming plate 2 , and the first film forming surface 101 is located on the upper surface of the tray 1 .

[0047] In some embodiments, the device includes a baffle 3 for forming a chamber together with the first film-forming surface and the second film-forming surface. When the first film-forming surface 101 is located at the outer edge of the second film-forming surface 201, The baffle 3 is located on the first film forming surface 101 . For example figure 1 As shown, the baffle 3 is fixed on the upper surface of the tray 1 . The baffle 3 is in the shape of a ring. When the film-forming plate 2 is accommodated in the tray groove 102, ...

Embodiment 2

[0061] Embodiment 2: The second film-forming surface is located at the outer edge of the first film-forming surface

[0062] The tray 1 has a protrusion 104, the first film-forming surface 101 is located on the upper surface of the protrusion 104, and the film-forming plate 2 has a through hole 203 for being sleeved on the protrusion. One end of the protrusion is connected with the tray, the other end of the protrusion is a free end, and the end surface of the free end of the protrusion is the upper surface of the protrusion.

[0063] In some embodiments, the protrusion 104 is cylindrical, such as Figure 5 shown.

[0064] In some embodiments, the device includes a baffle for forming a cavity together with the first film-forming surface and the second film-forming surface. When the second film-forming surface 201 is located at the outer edge of the first film-forming surface 101, the baffle The plate is located on the second film-forming surface. E.g Image 6 with Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com