Logistics sorting unit

A logistics and transmission unit technology, applied in sorting, conveyor objects, conveyors, etc., can solve the problems of inconvenient replacement, limited effective working time, O-belt breakage, etc., to avoid maintenance and improve overall operating efficiency , the effect of eliminating the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

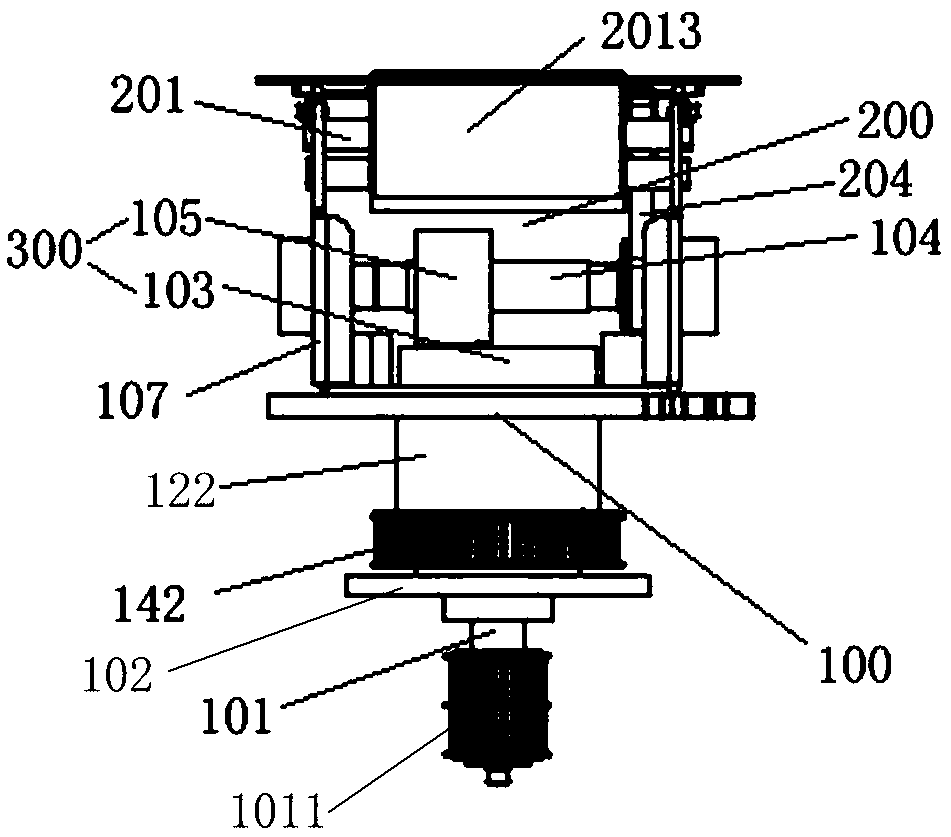

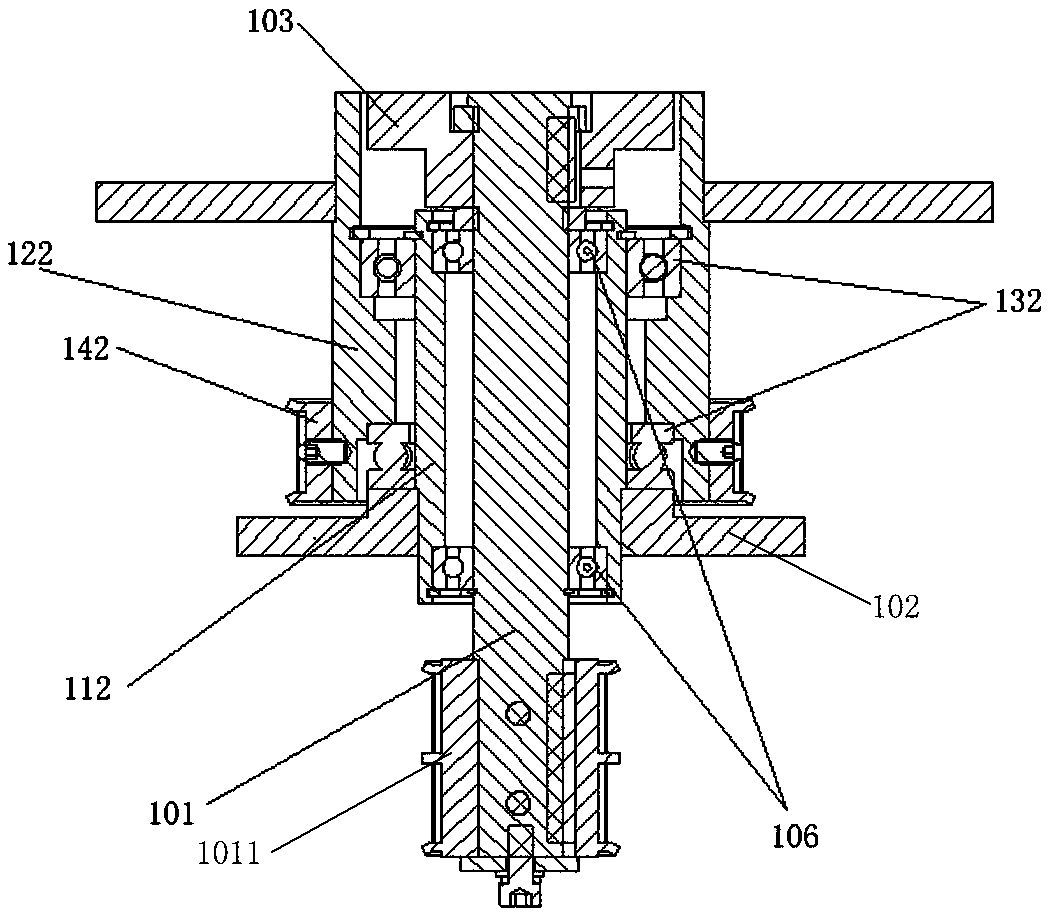

[0023] Such as figure 1 , 2 , 3, and 4 show a kind of material sorting unit, which includes a rotating transmission unit 200 and a driving unit 100 that are stacked up and down and whose overall outline is in the shape of a revolving body. An interval transmission mechanism 300 is installed in the drive unit 100, and the interval transmission mechanism 300 transmits the transmission force provided by the drive unit 100 to the transmission unit 200 during the overall horizontal phase angle rotation of the transmission unit 200, so that the transmission unit 200 maintains horizontal transmission of logistics packages state of motion.

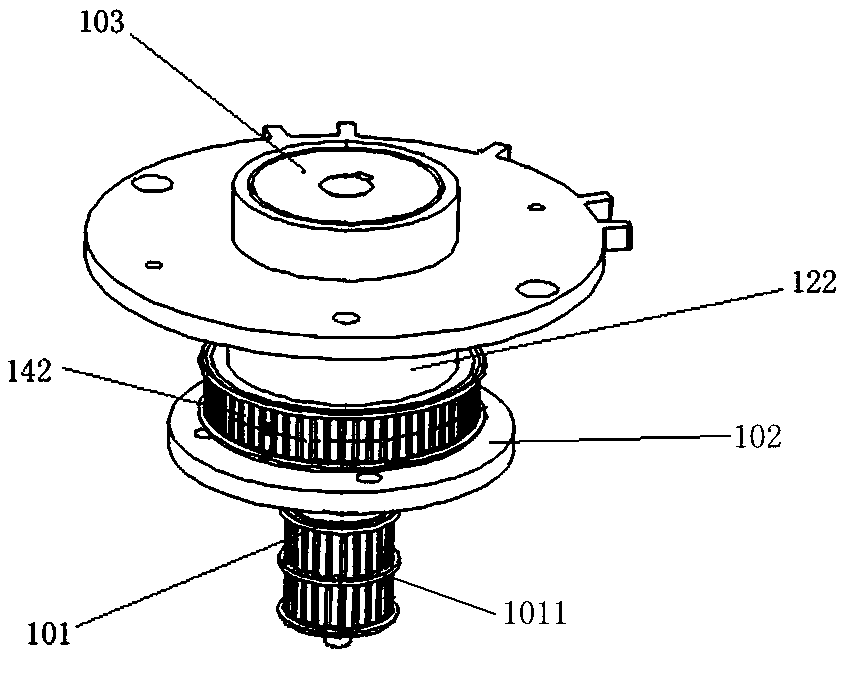

[0024] In this embodiment, the distance transmission mechanism 300 includes a vertical transmission shaft 101 and a magnetic disk 103 installed on the top of the transmission shaft 101 through a key connection and rotates therewith. One side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com