Profile steel supporting pile

A technology of support piles and section steel, which is applied in the direction of sheet pile walls, excavation, construction, etc., and can solve problems such as inclined pile insertion and difficult piling of section steel support piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

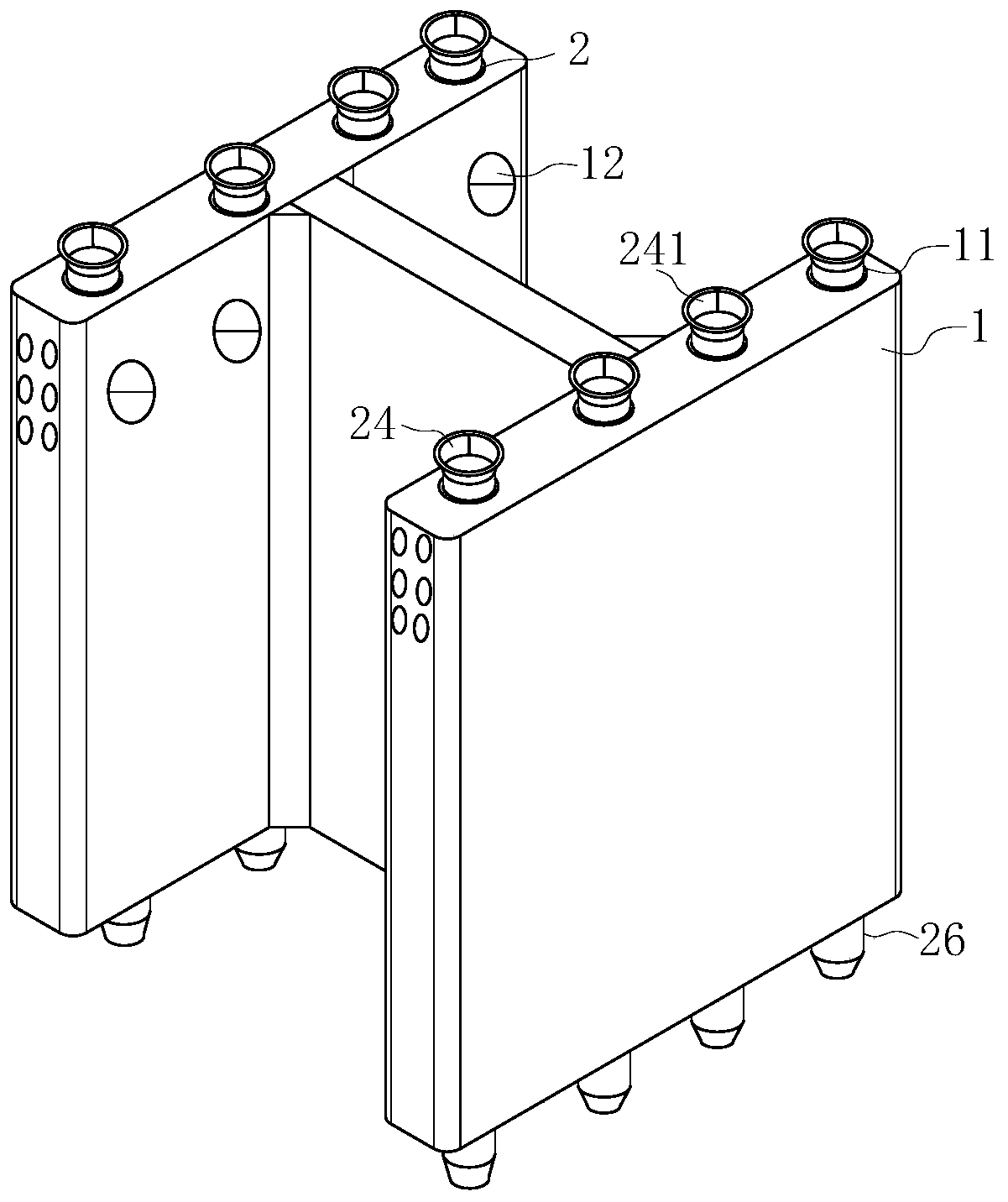

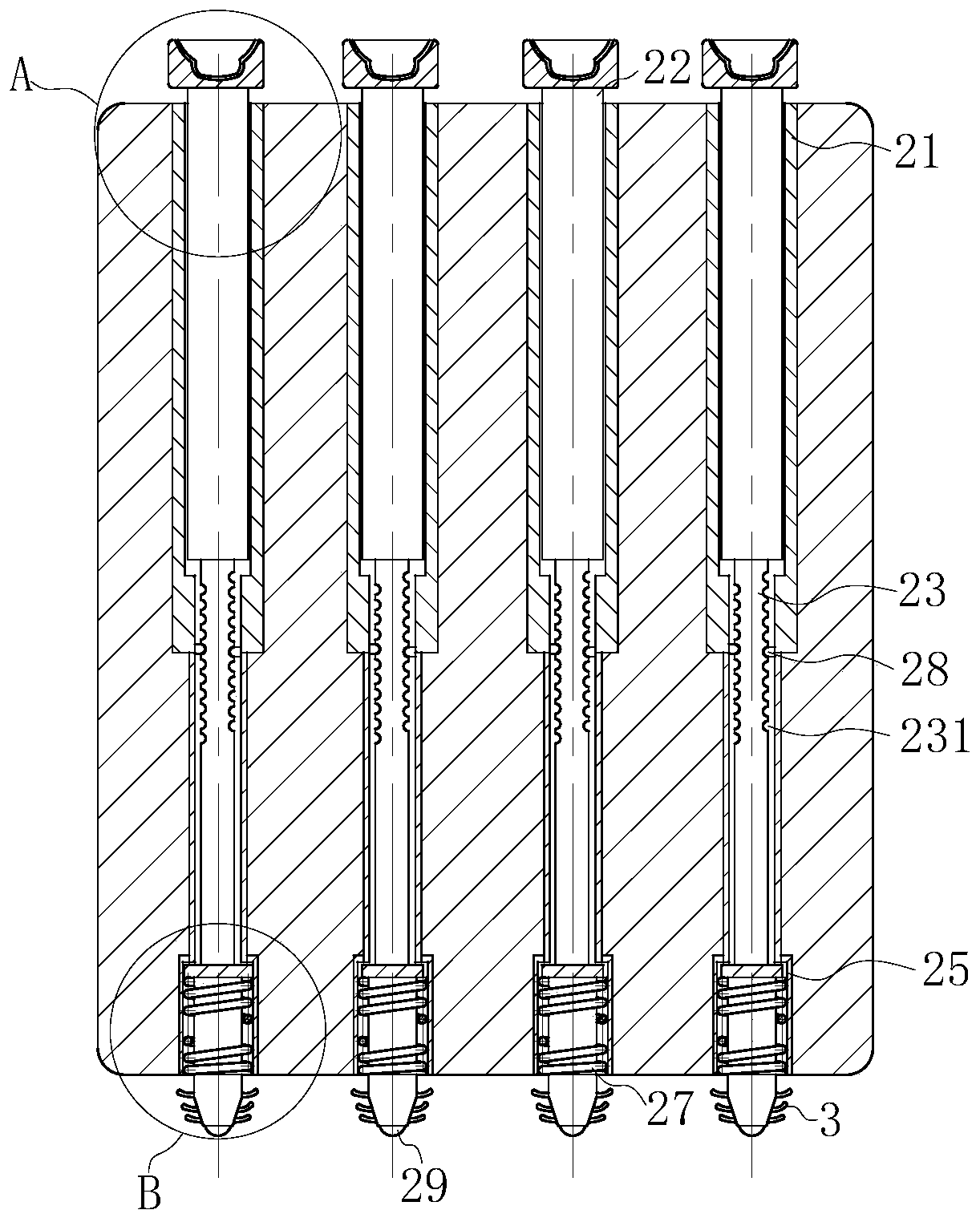

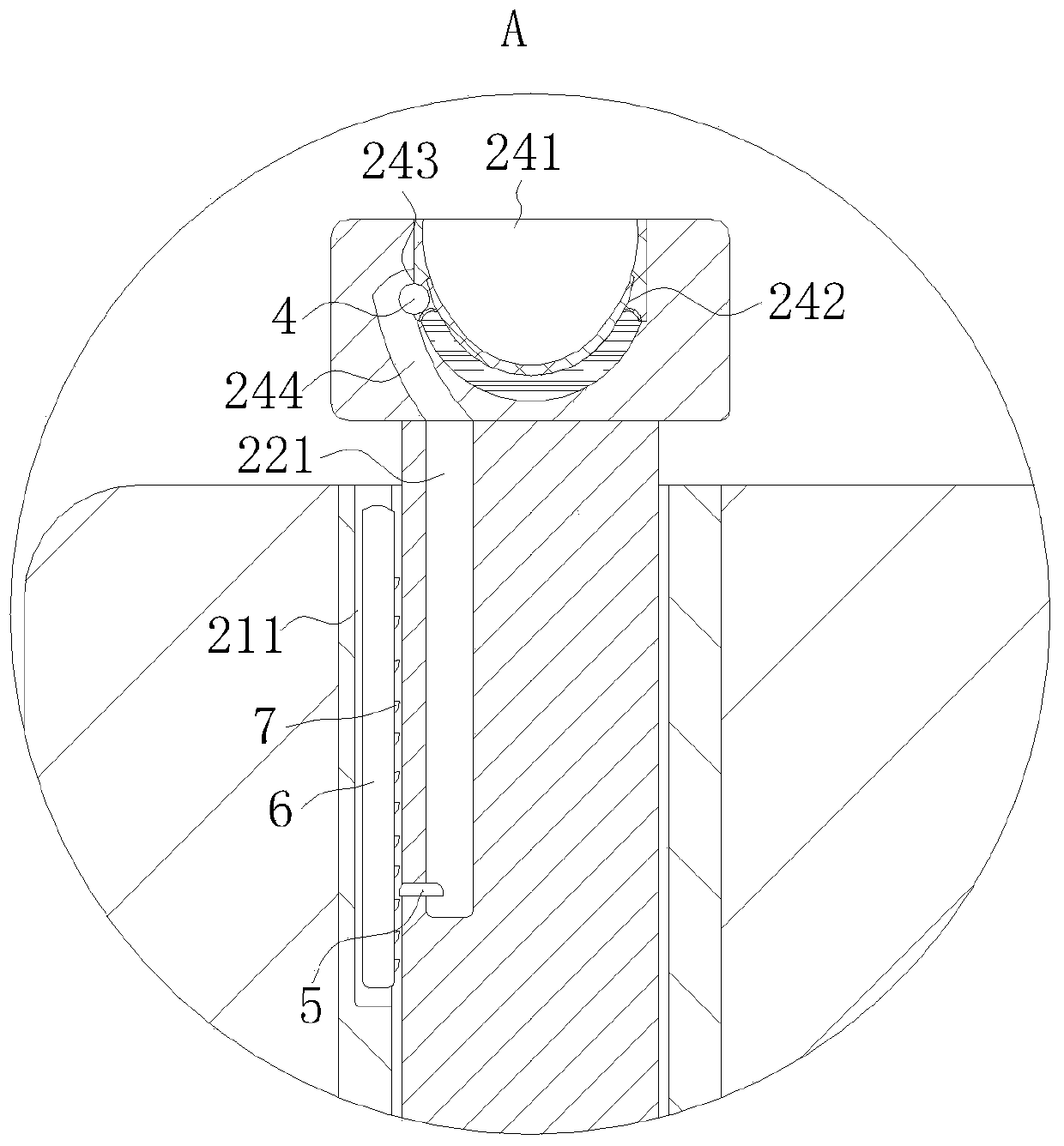

[0021] use Figure 1-Figure 5 A type of steel support pile according to one embodiment of the present invention will be described as follows.

[0022] Such as figure 1 , figure 2 with image 3As shown, a steel support pile according to the present invention includes a support pile body 1 and a drilling positioning unit 2; a stepped cavity 11 is evenly opened on the support pile body 1, and the stepped cavity 11 Both are provided with a drilling positioning unit 2; the drilling positioning unit 2 includes a protective sleeve 21, a support core 22, a rotating mandrel 23, a positioning block 24, a drill core sleeve 25, a bottom drill bit 26 and a torsion spring 27; The protective sleeve 21 is set in the stepped cavity 11, and a support core 22 is inserted into the protective sleeve; the bottom end of the support core 22 is connected with a rotating mandrel 23, and the bottom end of the support core 22 is provided with a positioning block 24 ; The rotating mandrel 23 is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap