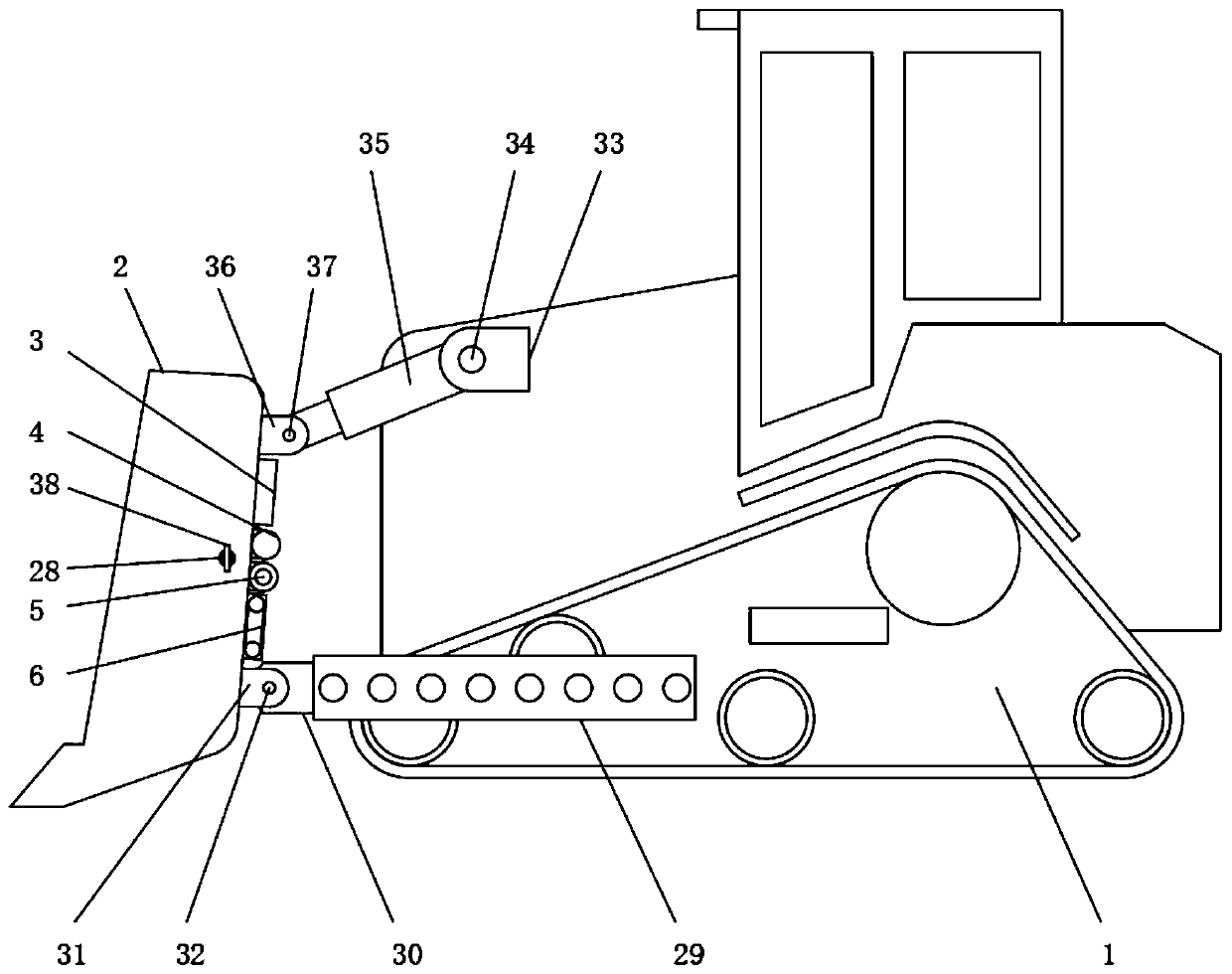

Construction bulldozer with clearing function

A technology for bulldozers and construction, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of sticking to the surface, unsatisfactory, time-consuming and labor-intensive, etc., achieve the effect of convenient installation and disassembly, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

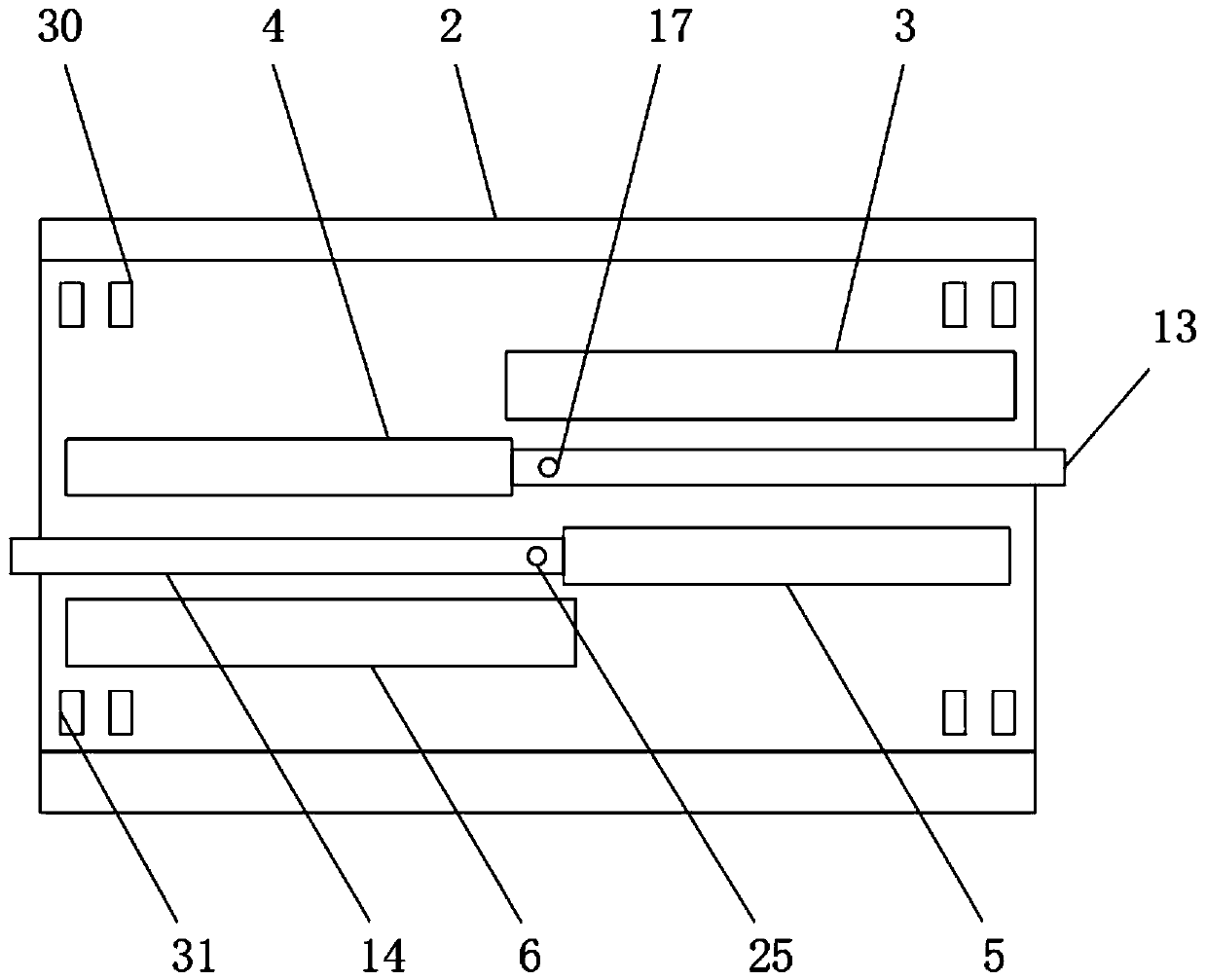

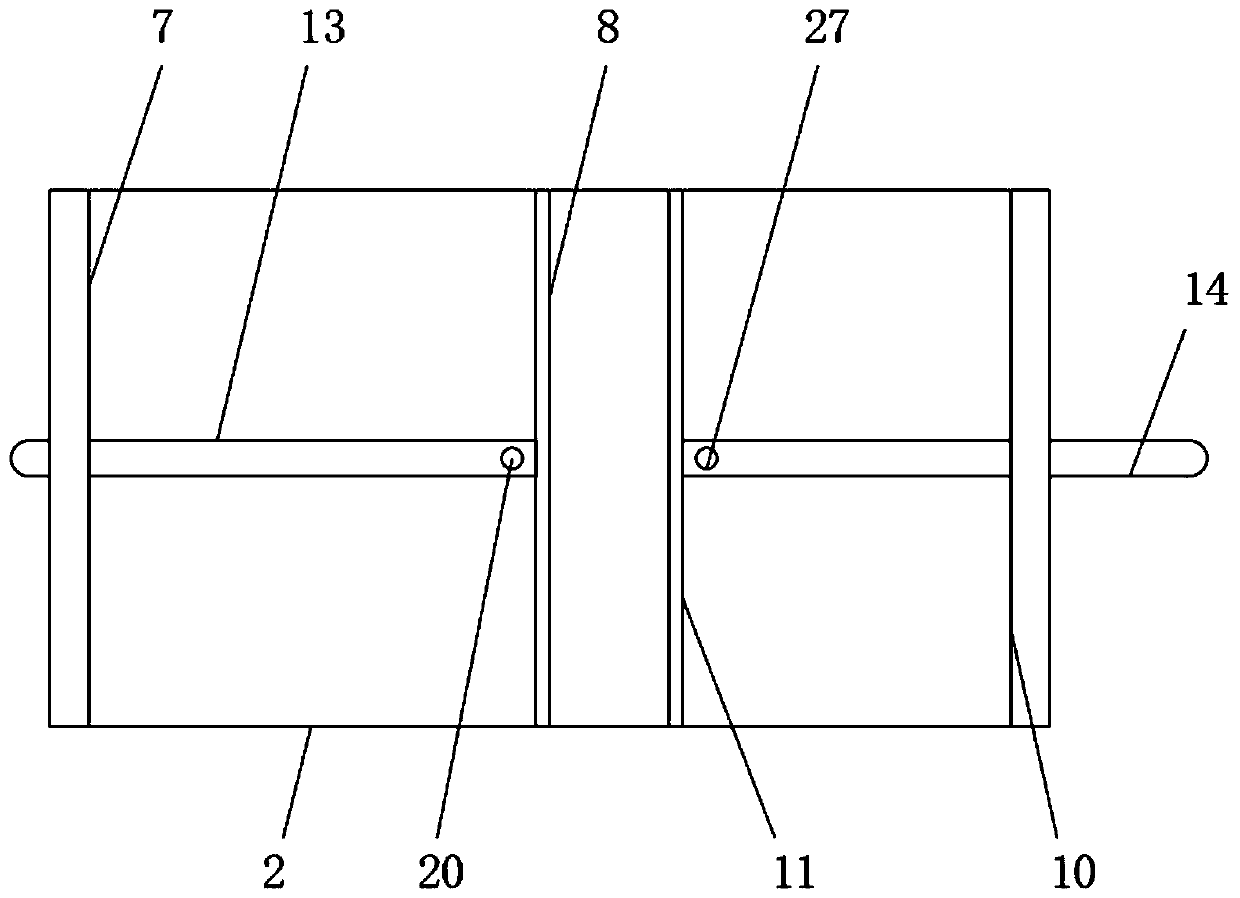

[0045] see figure 1 , when it is not necessary to clean up the clay for the bulldozing bucket 2, the connecting structure of the first U-shaped push rod 13 and the second U-shaped push rod 14 can be disconnected, and then the first U-shaped push rod 13 is put into the Inside the first collection box 3, put the second U-shaped push rod 14 into the inside of the second collection box 6, and the first collection box 3 and the second collection box 6 are all hinged with sealing covers, and use the second locking Bolt 20 fixedly connects the first fixed column 9 with the stopper 38, and the second fixed column 12 is fixedly connected with the stopper 38 with the fourth locking bolt 27, and the stopper 38 can connect the first fixed column 9 and the second fixed column 12 is fixed in the through hole 28, and the first cleaning scraper 8 is fixed in the first baffle 7, and the second cleaning scraper 11 is fixed in the second baffle 10, which does not affect the use of the bulldozing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com