Low-temperature environment assembled shear wall construction method

A technology of low temperature environment and construction method, which is applied in thermal insulation, processing of building materials, building components, etc., can solve the problems of inability to construct prefabricated concrete shear walls and slow construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

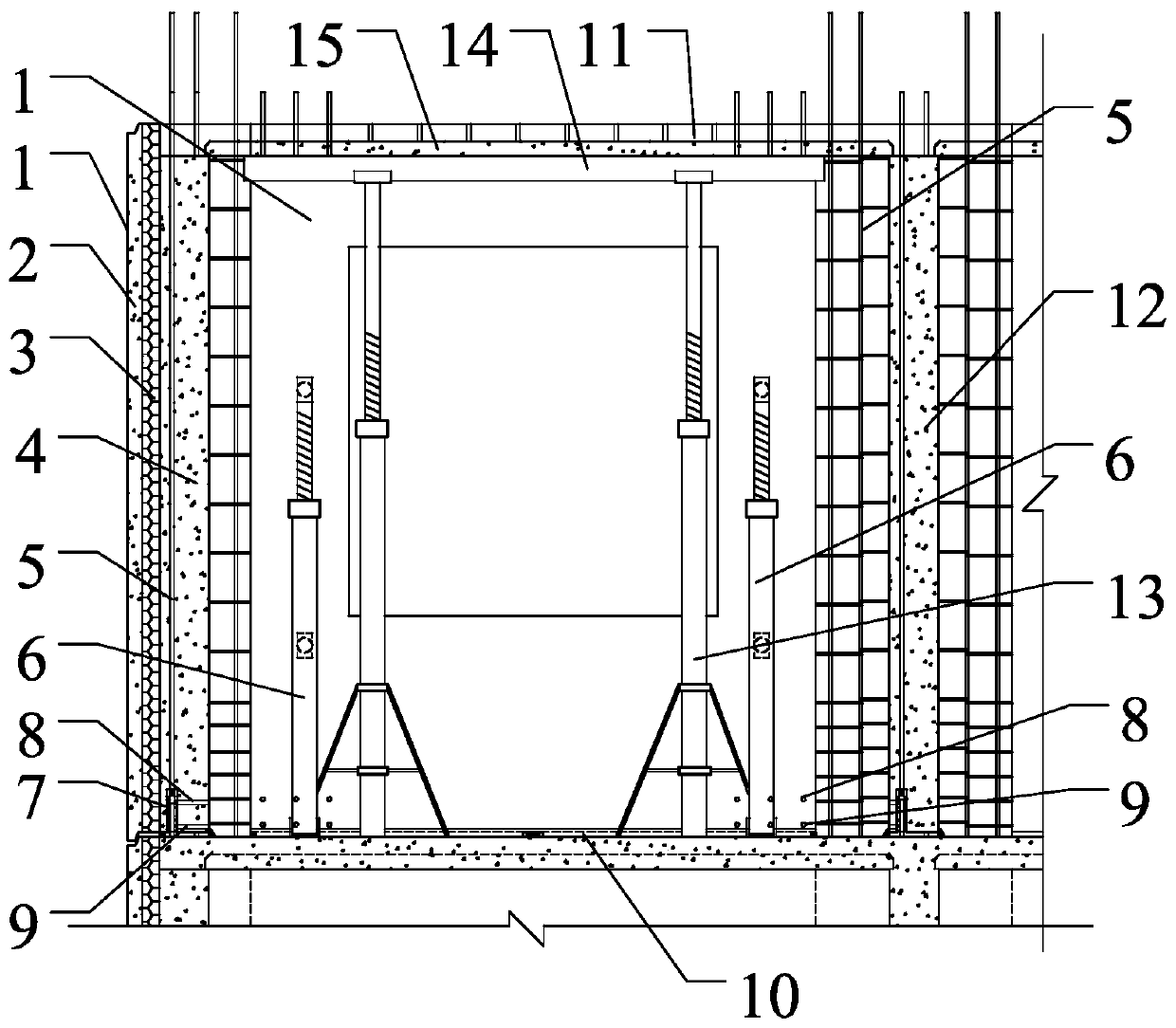

[0026] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0027] figure 1 It is a structural schematic diagram of a prefabricated shear wall in a low temperature environment according to the present invention. A construction method for a prefabricated shear wall in a low temperature environment comprises the following steps:

[0028] S1, prefabricated components, prefabrication of exterior wall panels 1, interior wall panels 12, and laminated slab prefabricated floor 15, and the previously installed exterior wall panels 1, interior wall panels 12, and cast-in-place concrete under various working conditions of grouting construction Carry out simulated force analysis, and each working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com