A crack-resistant inorganic waterproof material

A waterproof material and anti-crack technology, applied in the field of anti-crack inorganic waterproof materials, can solve the problems of large residual stress of the coating, easy cracking of the paint film, shortened service life, etc., to achieve good waterproof effect and improve work efficiency. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

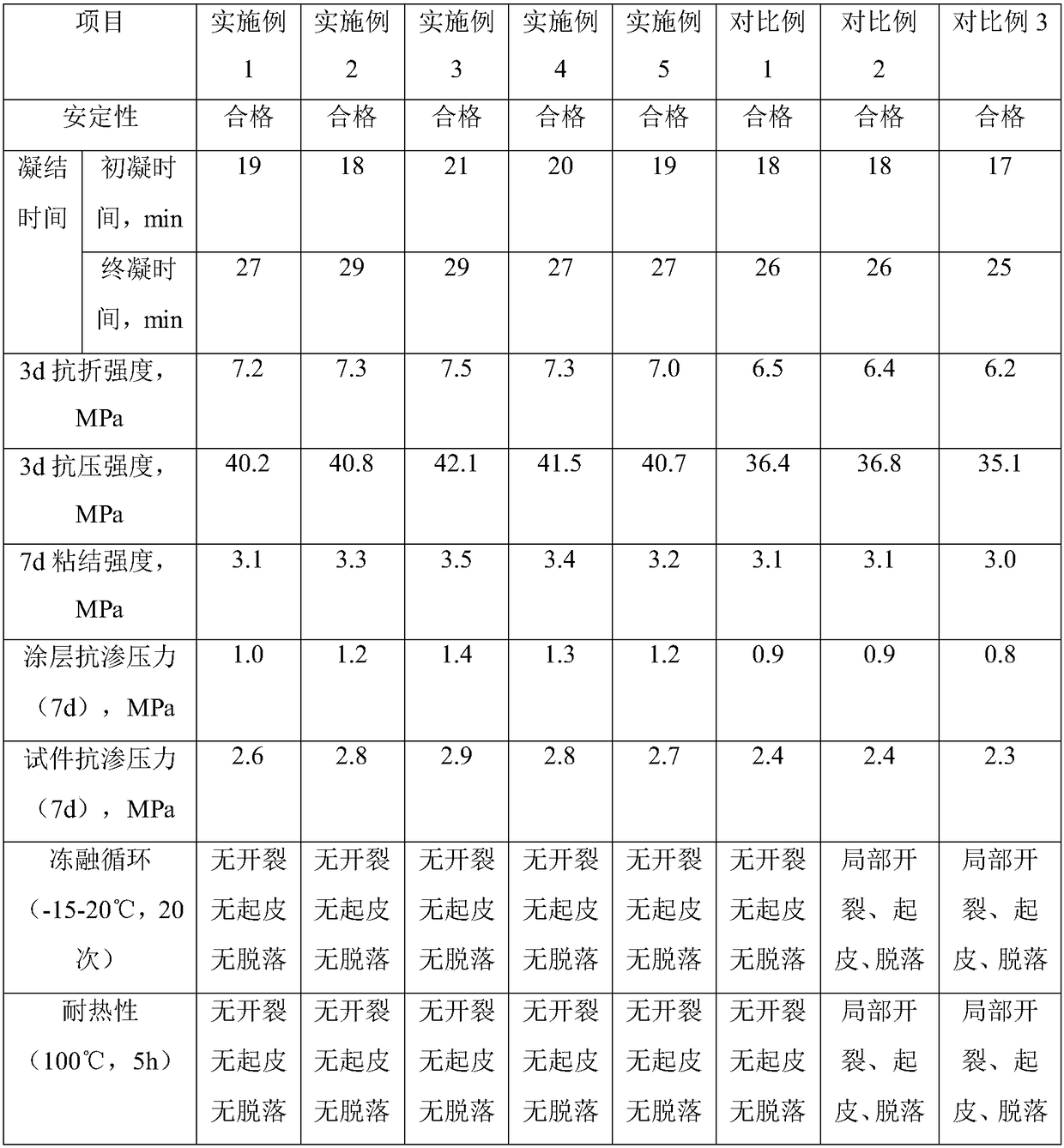

Examples

Embodiment 1

[0032] An anti-cracking inorganic waterproof material is composed of the following raw materials in parts by weight: 94.6 parts of gelling material, 0.5 parts of flow modifier, 1.5 parts of anti-cracking agent, 3.2 parts of organic additives, and 4 parts of inorganic additives;

[0033] The cementitious material is obtained by mixing sulphoaluminate cement, fly ash and filler according to the weight ratio of 1:0.6:0.3;

[0034] The flow modifier is obtained by mixing polyethylene oxide and ethoxy diglycol ether in a weight ratio of 1:1.2;

[0035] The anti-cracking agent is obtained by mixing ethylene glycol distearate, sodium polyphosphate and magnesium fluorosilicate according to the weight ratio of 1:0.3:0.7;

[0036] The organic additive is obtained by mixing magnesium stearate, organic silicon, water reducing agent and hydroxyethyl cellulose according to the weight ratio of 1:1.2:0.8:0.4;

[0037] The inorganic additive is composed of steel slag fine powder and graphite ...

Embodiment 2

[0043] An anti-cracking inorganic waterproof material is composed of the following raw materials in parts by weight: 93.8 parts of gelling material, 0.6 parts of flow modifier, 2.0 parts of anti-cracking agent, 3.0 parts of organic additives, and 4.5 parts of inorganic additives;

[0044] The cementitious material is obtained by mixing sulphoaluminate cement, fly ash and filler according to the weight ratio of 1:0.65:0.25;

[0045] The flow modifier is obtained by mixing polyethylene oxide and ethoxy diglycol ether in a weight ratio of 1:1.1;

[0046] The anti-cracking agent is obtained by mixing ethylene glycol distearate, sodium polyphosphate and magnesium fluorosilicate according to the weight ratio of 1:0.4:0.8;

[0047] The organic additive is obtained by mixing magnesium stearate, organic silicon, water reducing agent and hydroxyethyl cellulose according to the weight ratio of 1:1.0:0.9:0.5;

[0048] The inorganic additive is composed of steel slag fine powder and graph...

Embodiment 3

[0054] An anti-cracking inorganic waterproof material is composed of the following raw materials in parts by weight: 93.0 parts of gelling material, 0.7 parts of flow modifier, 2.5 parts of anti-cracking agent, 2.8 parts of organic additives, and 5 parts of inorganic additives;

[0055] The cementitious material is obtained by mixing sulphoaluminate cement, fly ash and filler according to the weight ratio of 1:0.65:0.2;

[0056] The flow modifier is obtained by mixing polyethylene oxide and ethoxy diglycol ether in a weight ratio of 1:1.0;

[0057] The anti-cracking agent is obtained by mixing ethylene glycol distearate, sodium polyphosphate and magnesium fluorosilicate according to the weight ratio of 1:0.4:0.8;

[0058] The organic additive is obtained by mixing magnesium stearate, organic silicon, water reducing agent and hydroxyethyl cellulose according to the weight ratio of 1:0.8:0.9:0.5;

[0059] The inorganic additive is composed of steel slag fine powder and graphite i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com