Steam turbine generator set maintenance barring gear

A turbogenerator set, inspection and maintenance barring technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of inconvenient installation, assembly and disassembly, etc., and achieve the effect of simple assembly and disassembly, good rigidity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

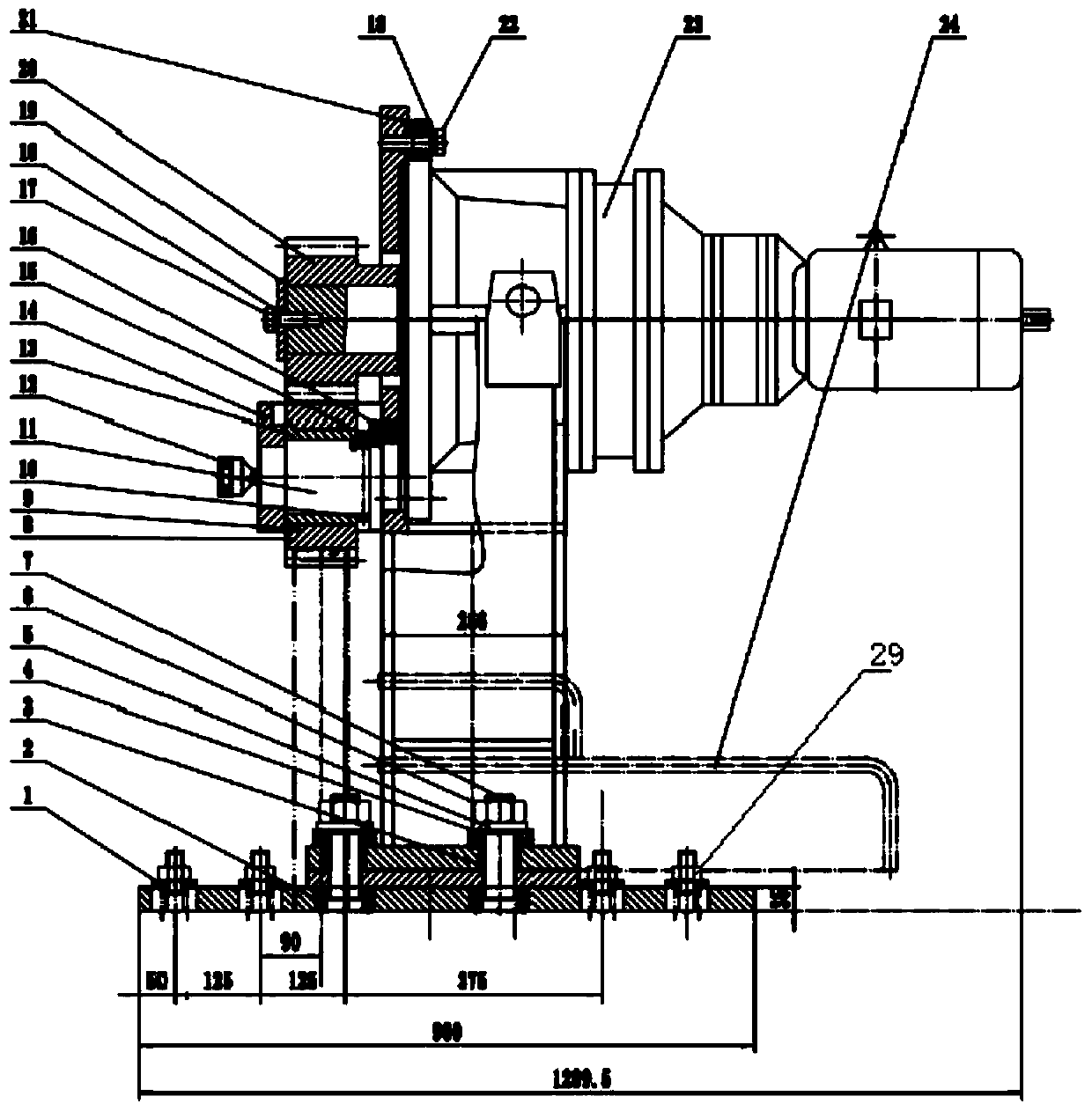

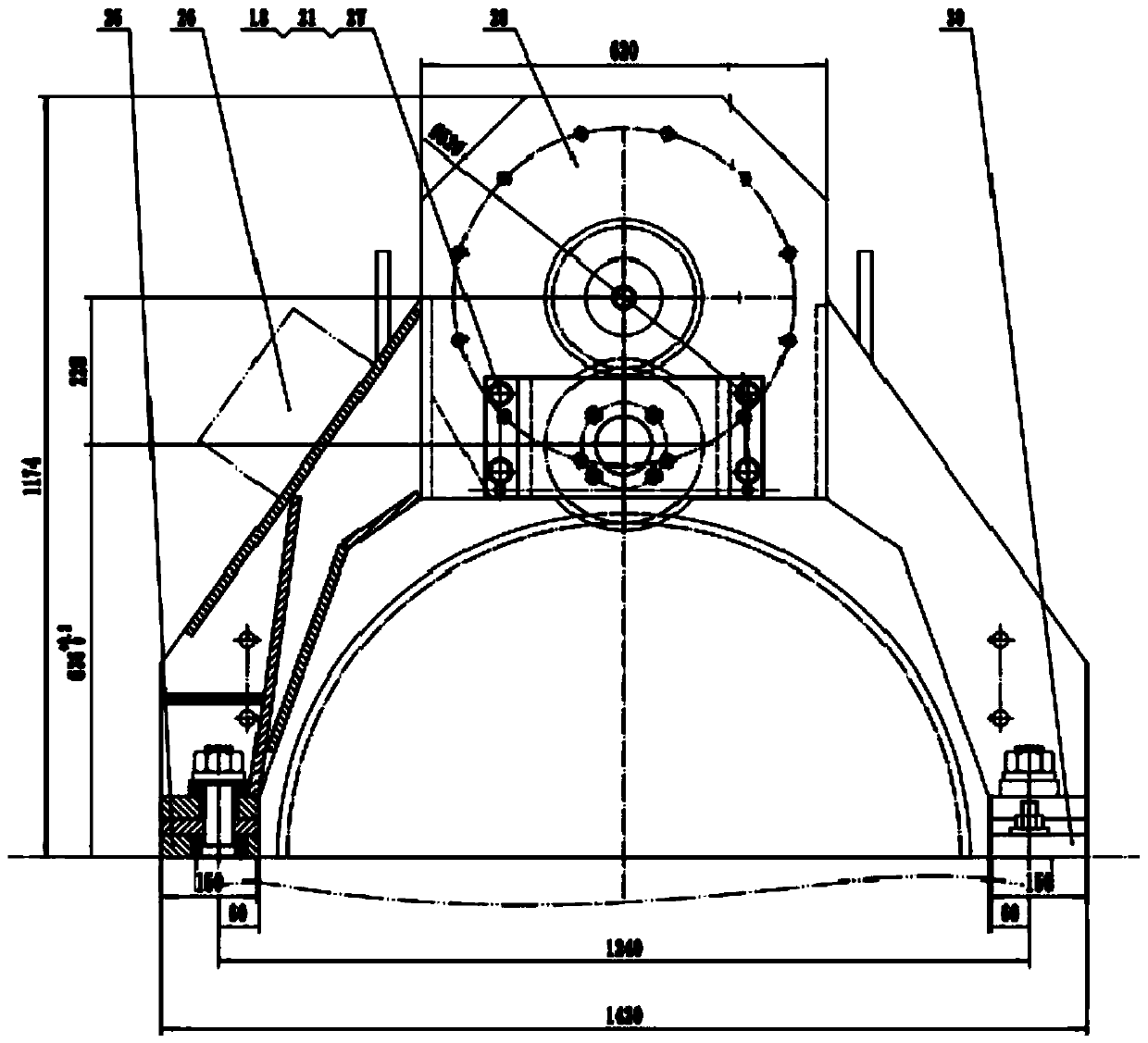

[0016] Such as Figure 1-2 As shown, a turbogenerator set maintenance barring includes a left bracket 25, a right bracket 30, a crossbeam 28, a cycloidal pinwheel reducer 23 and a storage bracket 24, and the tops of the left bracket 25 and the right bracket 30 are installed by The fastening bolt 7 is installed in the hole, and the top of the fastening bolt 7 runs through the bottom of the installation crossbeam 28, and the top of one side of the crossbeam 28 is installed with a cycloidal pinwheel reducer 23 through the No. 1 bolt 22, and one end of the cycloidal pinwheel reducer 23 It has a direct-coupled motor, and the other end of the cycloid reducer 23 is clamped with the driving gear 20 around the rotating shaft, and one end of the rotating shaft is installed with a shaft end retaining ring 19 through the second bolt 17, and the transition shaft 11 is welded at the bottom of the driving gear 20 A transition gear 8 is set on the periphery of the transition shaft 11, and the...

Embodiment 2

[0022] Such as Figure 1-2 As shown, a turbogenerator set maintenance barring includes a left bracket 25, a right bracket 30, a crossbeam 28, a cycloidal pinwheel reducer 23 and a storage bracket 24, and the tops of the left bracket 25 and the right bracket 30 are installed by The fastening bolt 7 is installed in the hole, and the top of the fastening bolt 7 runs through the bottom of the installation crossbeam 28, and the top of one side of the crossbeam 28 is installed with a cycloidal pinwheel reducer 23 through the No. 1 bolt 22, and one end of the cycloidal pinwheel reducer 23 It has a direct-coupled motor, and the other end of the cycloid reducer 23 is clamped with the driving gear 20 around the rotating shaft, and one end of the rotating shaft is installed with a shaft end retaining ring 19 through the second bolt 17, and the transition shaft 11 is welded at the bottom of the driving gear 20 A transition gear 8 is set on the periphery of the transition shaft 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com