Tapered Roller Bearings for Differentials

A technology of tapered roller bearings, differentials, applied in the direction of ball bearings, shafts and bearings, bearing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

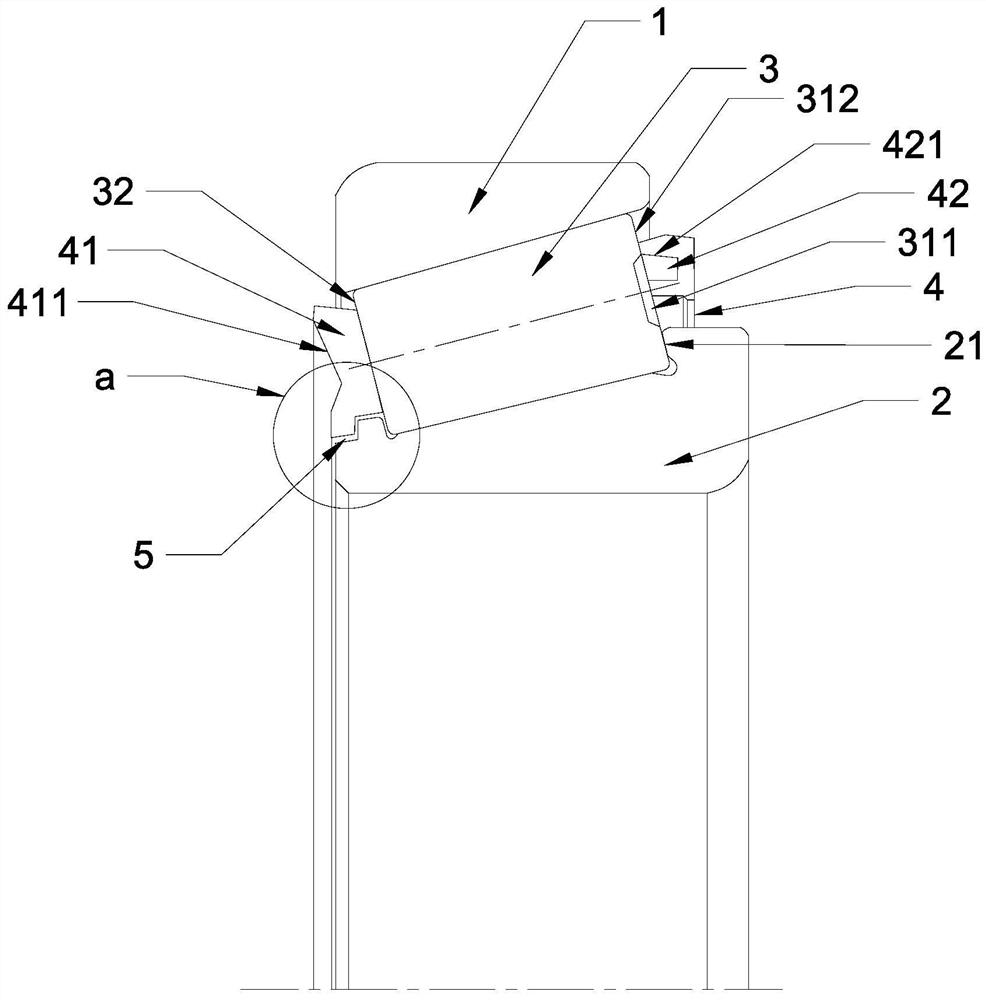

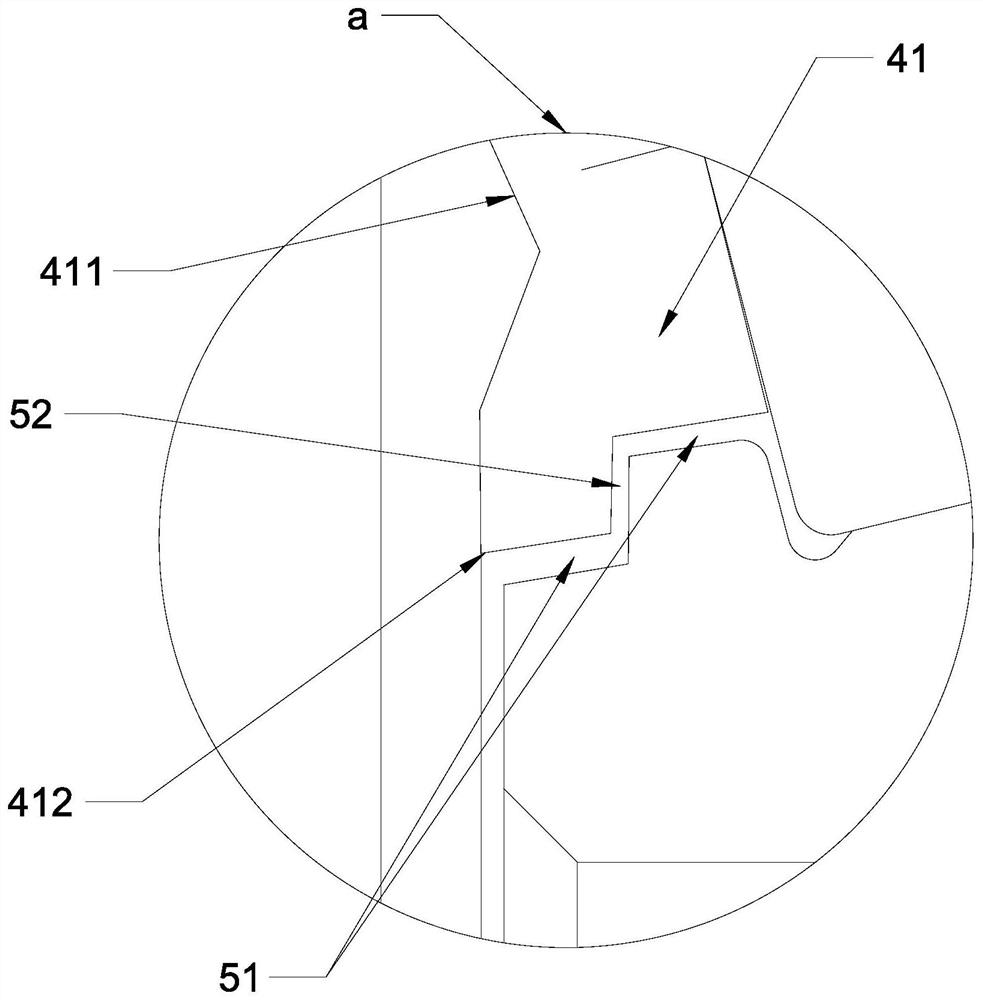

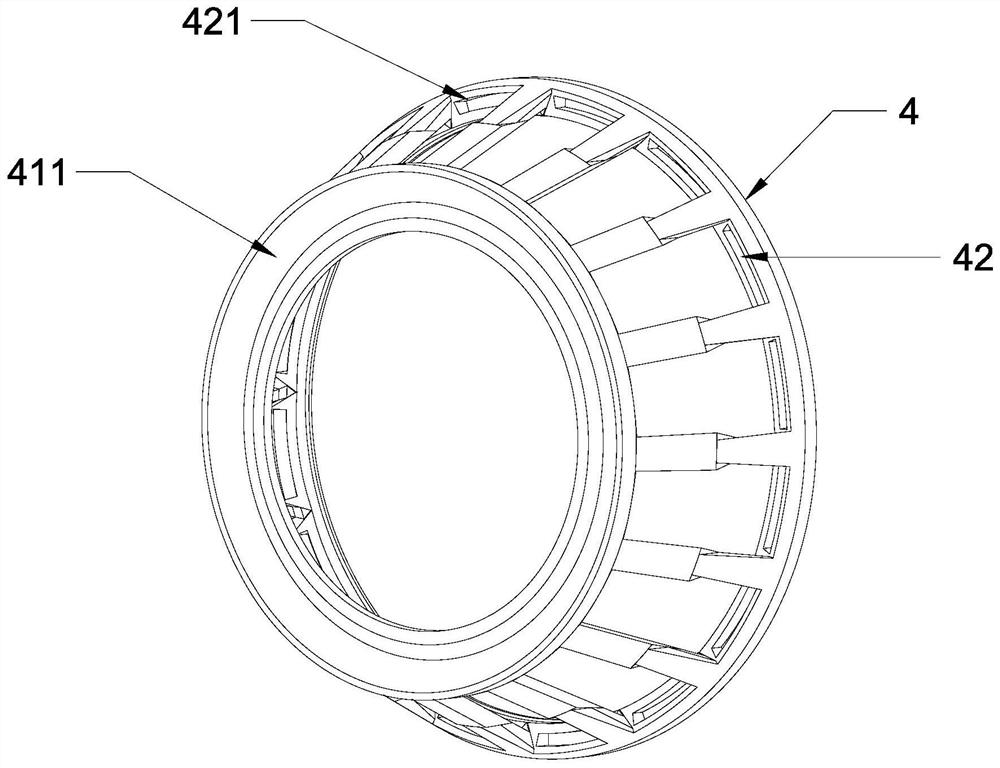

[0027] Embodiment 1 of the tapered roller bearing of the present invention is as Figure 1-4 As shown: it includes an outer ring 1, an inner ring 2, a roller 3, and a cage 4. The roller 3 includes a large end 31 and a small end 32. The cage 4 includes a The annular recess 41 at the end 32 is arranged along the axis of the roller 3 toward the outside of the bearing. The annular recess 41 includes an oil throwing surface 411 near the outer ring of the bearing, and the oil throwing surface 411 It is inclined toward the outside of the bearing, and the inner edge of the annular recess 41 and the inner ring of the bearing form a flow-limiting channel 5 . The annular recess 41 and the cage 4 are processed from one piece of profile. In this embodiment, the annular recess 41 and the cage 4 are stamped and formed of metal material. The flow-limiting passage 5 is stepped, and the flow-limiting passage 5 includes two drainage sections 51 and a connecting section 52 connecting the two dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com