Osmotic pressure device and testing method used for high-pressure solid bentonite test

A technology of bentonite and high-pressure compaction, which is applied in the direction of measuring devices, applying stable tension/pressure to test material strength, and preparation of test samples, which can solve the problem of poor data representation of expansion force data collection points and difficulty in completely saturating soil , the test results are greatly affected, etc., to achieve the effect of avoiding uneven hydration and good anisotropy characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

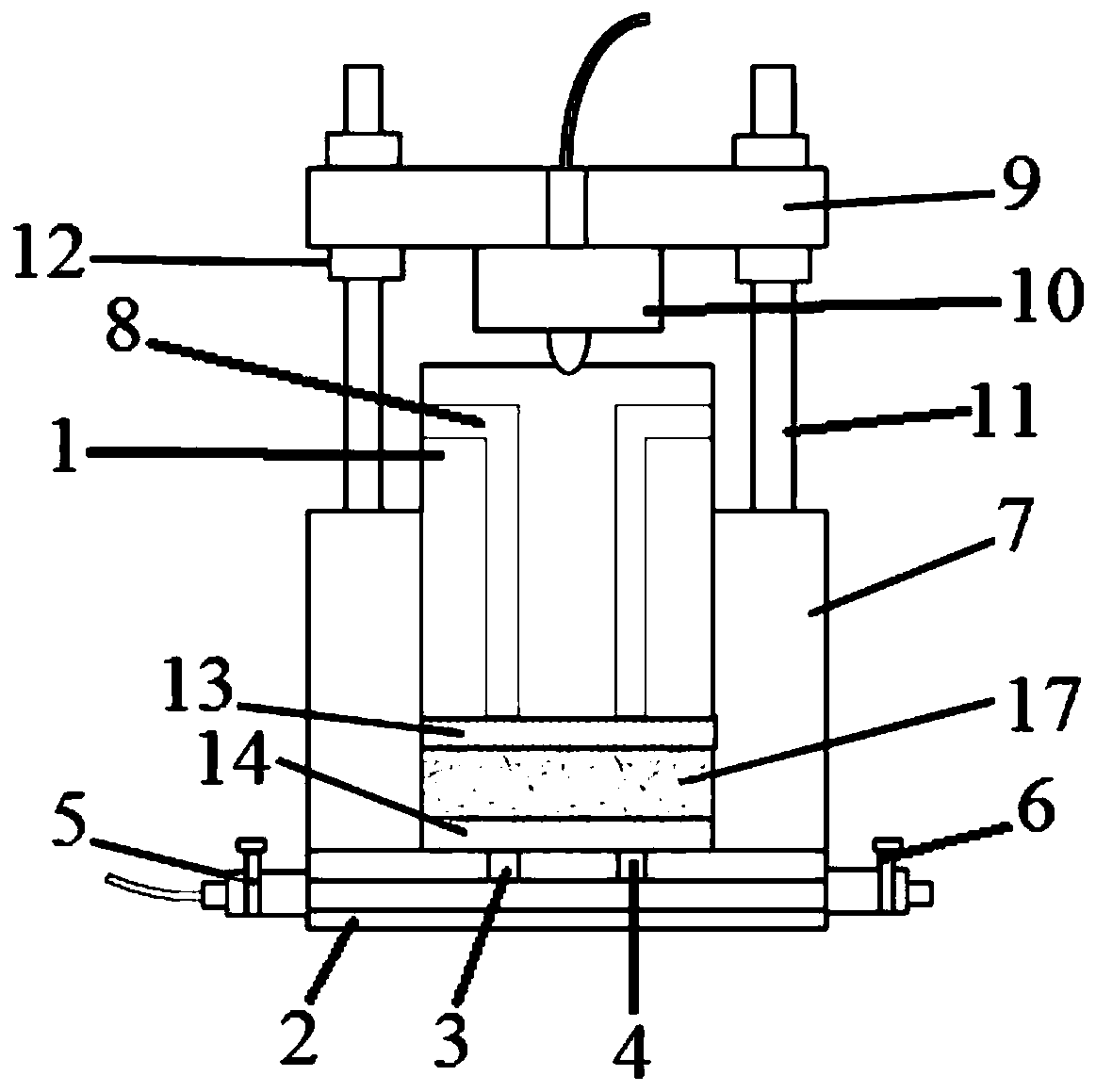

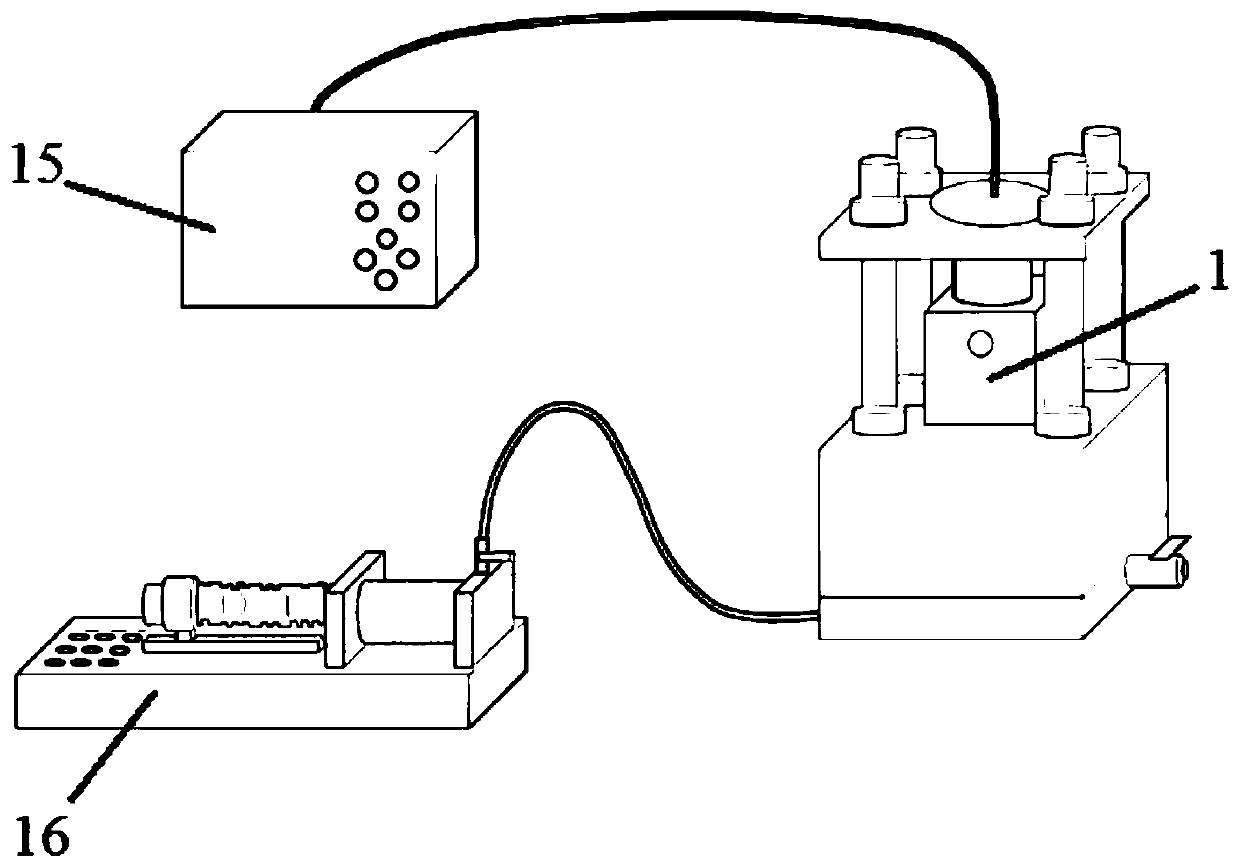

[0028] Such as figure 1 The osmotic pressure device used for the high-compacted bentonite test is shown, including the bottom water injection and exhaust mechanism, the side closure mechanism arranged on the bottom water injection and exhaust mechanism, and the side closure mechanism inserted in the side closure mechanism and sliding with the side closure mechanism The connected piston 1, the bottom water injection exhaust mechanism, the side sealing mechanism and the piston 1 form a bentonite test chamber. The bentonite test chamber is square, and the height of the bentonite test chamber is smaller than the width.

[0029] Wherein, the bottom water injection and exhaust mechanism includes a base plate 2 and a base plate water injection channel and a base plate exhaust channel respectively opened in the base plate 2. The base plate 2 is provided with a base plate water injection hole 3 connected with the base plate water injection channel and connected with the base plate exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com