Method for etching deep through silicon via (TSV)

A technology of deep silicon and etching depth, applied in chemical instruments and methods, processes for producing decorative surface effects, decorative arts, etc., can solve the problem of reducing silicon etching speed, difficult to achieve high-speed etching, reducing etching speed and other issues, to achieve the effects of good anisotropy, prolonged time, and high etching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

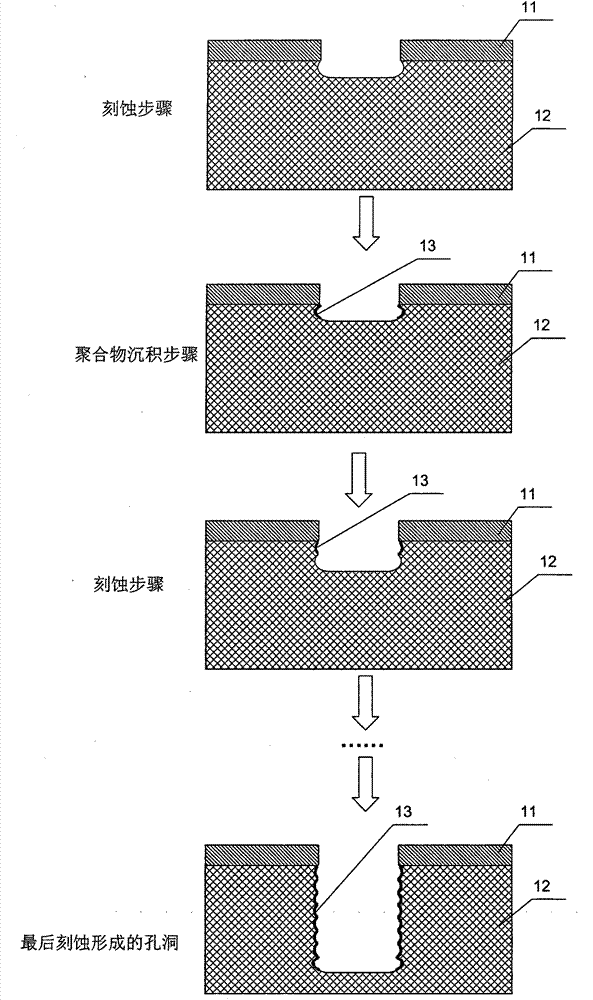

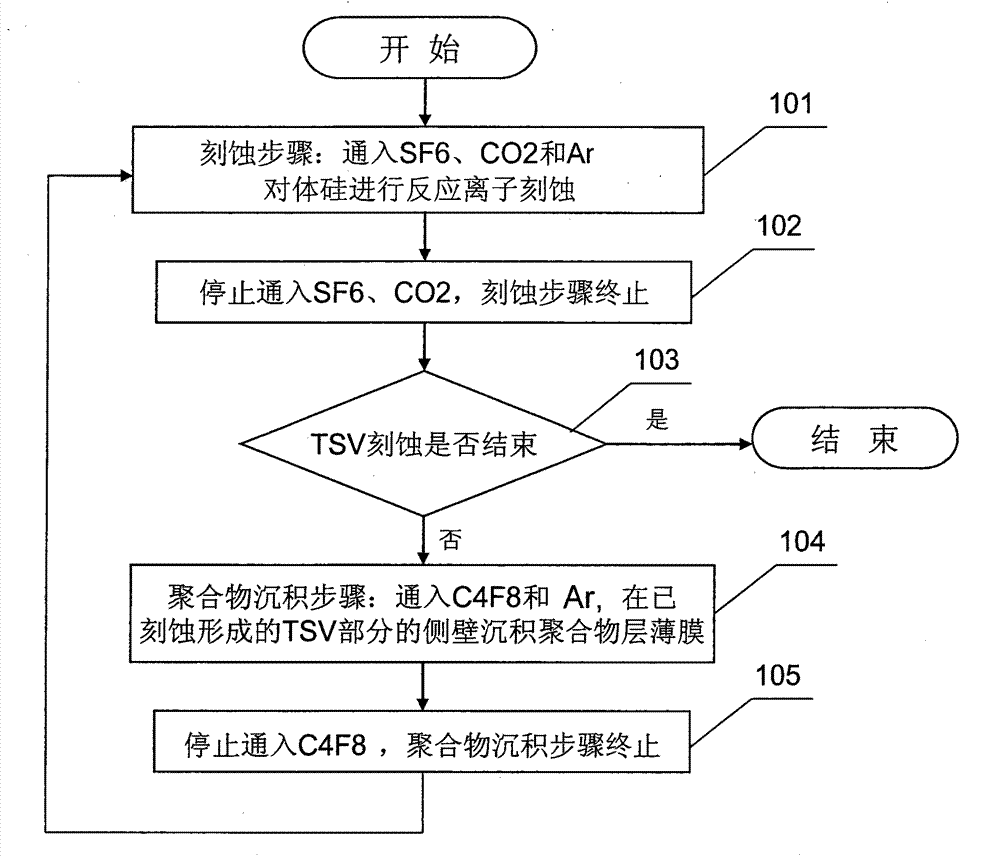

[0017] figure 2 Shown is a schematic flow chart of the TSV etching method according to the first embodiment of the present invention. In the TSV etching method, it is used to etch bulk silicon, and the shape parameters such as the depth, width, and aperture of the TSV through holes that are specifically required to be etched are not limited by the present invention, and can be determined according to different process conditions. In this example, 60 μm deep TSV vias are etched. The following specific steps are figure 2 The TSV etching method of the first embodiment shown is described in detail.

[0018] Step 101, etching step: injecting SF 6 , CO 2 and Ar, reactive ion etching of bulk silicon.

[0019] In this step, reactive ion etching is used to etch the bulk silicon, on which there are such figure 1 The mask layer shown in 11 is used to pattern the TSV. In this specific embodiment, the etching reaction chamber adopts the capacitively coupled plasma source technolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com