Method for passivating films shielded by etching adhesive through fluorine-based gas

A gas and thin film technology, applied in the field of thin films masked by fluorine-based gas passivation etchant, can solve problems such as difficult to completely remove, pollution, and corrosion of laminated structure materials, and achieve good anisotropy and easy removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

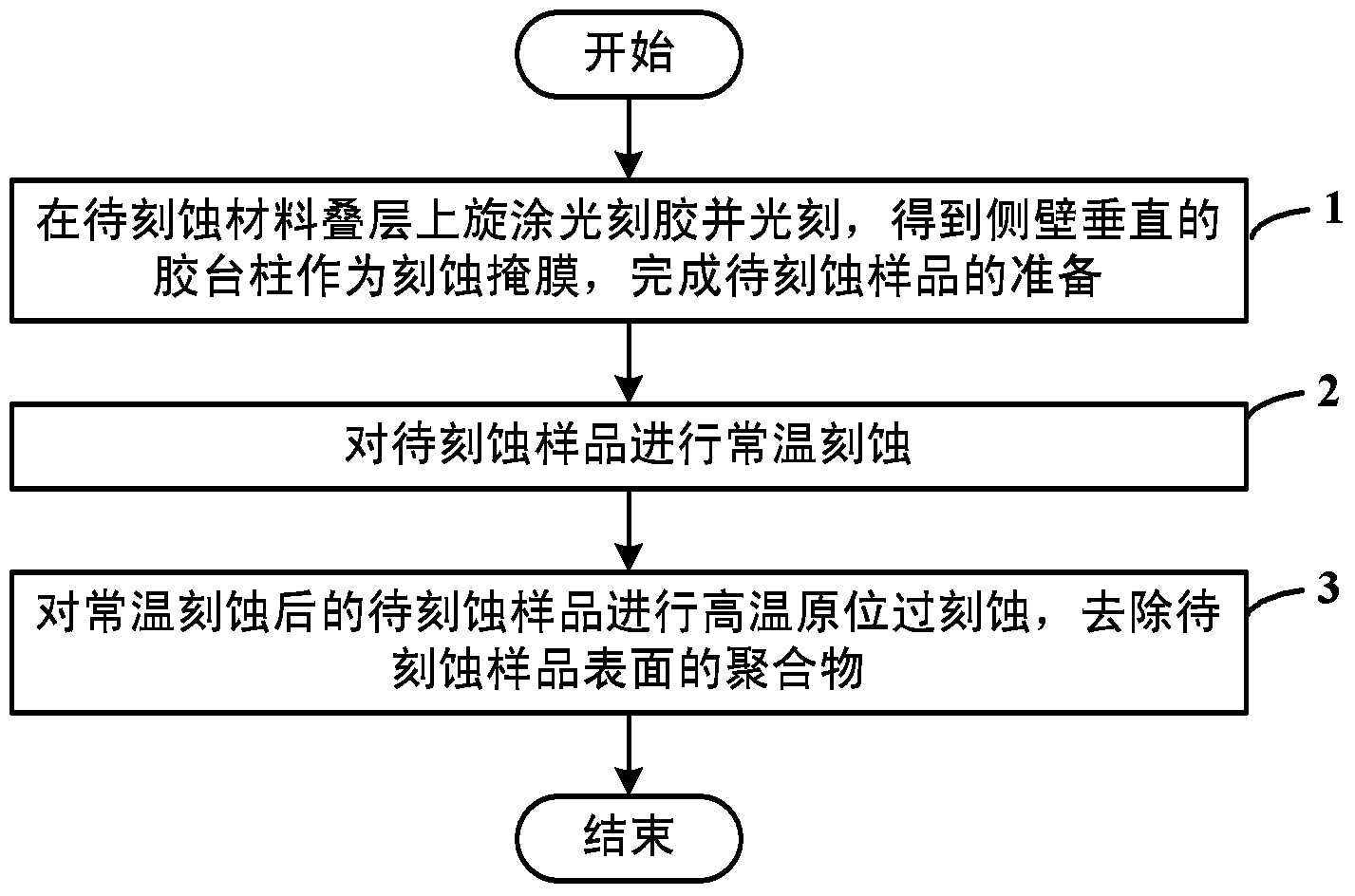

Method used

Image

Examples

Embodiment Construction

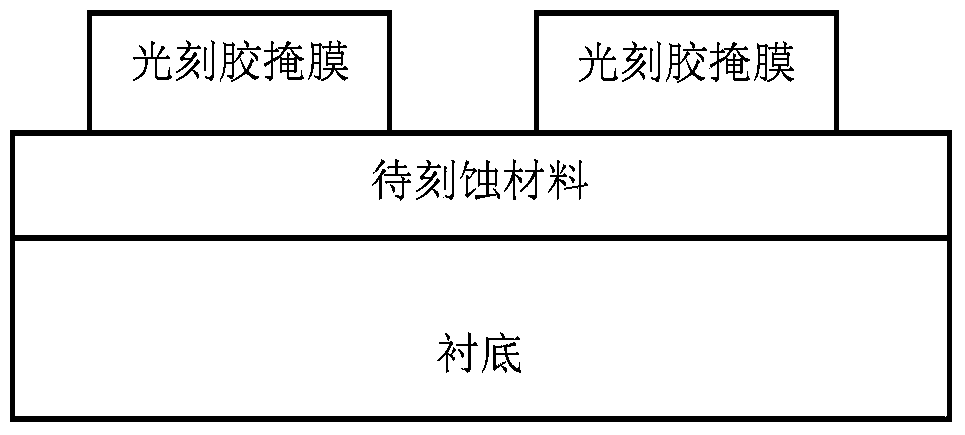

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

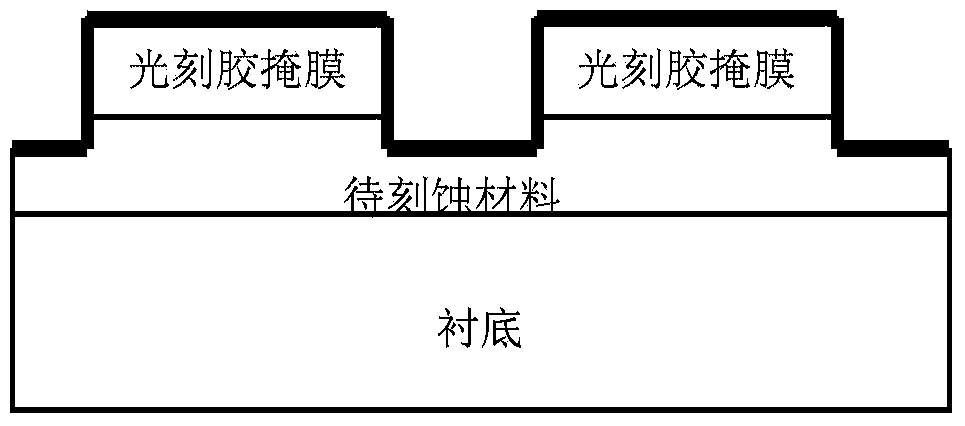

[0033] The present invention utilizes the advantages of high-temperature etching, which is mainly reflected in the fact that the carbon element in the reactive ion etching gas participates in the reaction to form a polymer, which is relatively volatile when the temperature is about 100° C.; There is cooling, but the temperature will still rise during the long-term etching process. Even if the photoresist mask is thicker, the solvent in the glue can be fully baked, and a harder high-temperature etching-resistant glue mask can be obtained.

[0034]In addition, when the pressure and gas flow rate of the etching chamber are constant, the temperature rise will cause the equipment control system to increase the vacuum pumping ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com