Field method for producing seeds by hybrid rice parents transplanting and harvesting integrated machine

A parent-parent and hybrid rice technology, applied in the field of field planning, planting, harvesting, and seed production, can solve the problems of narrow application area, inability to popularize and apply in a large area, and inability to turn around, so as to improve production efficiency and benefit, and increase female parent harvest output , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

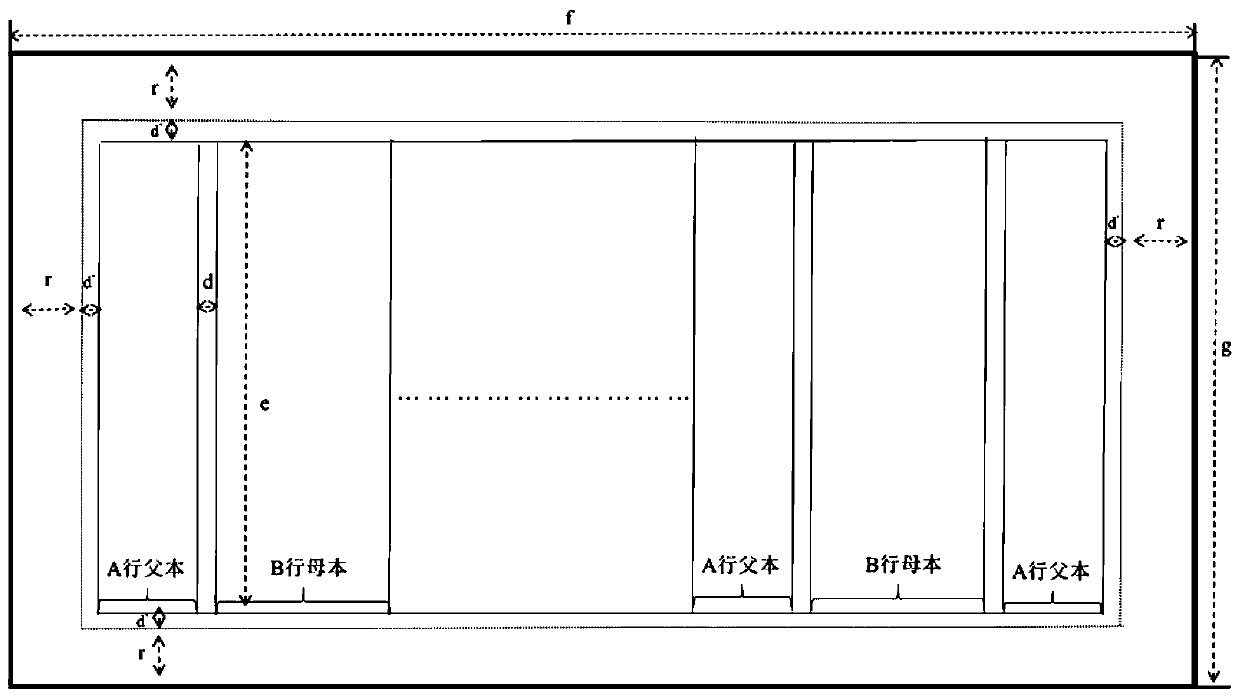

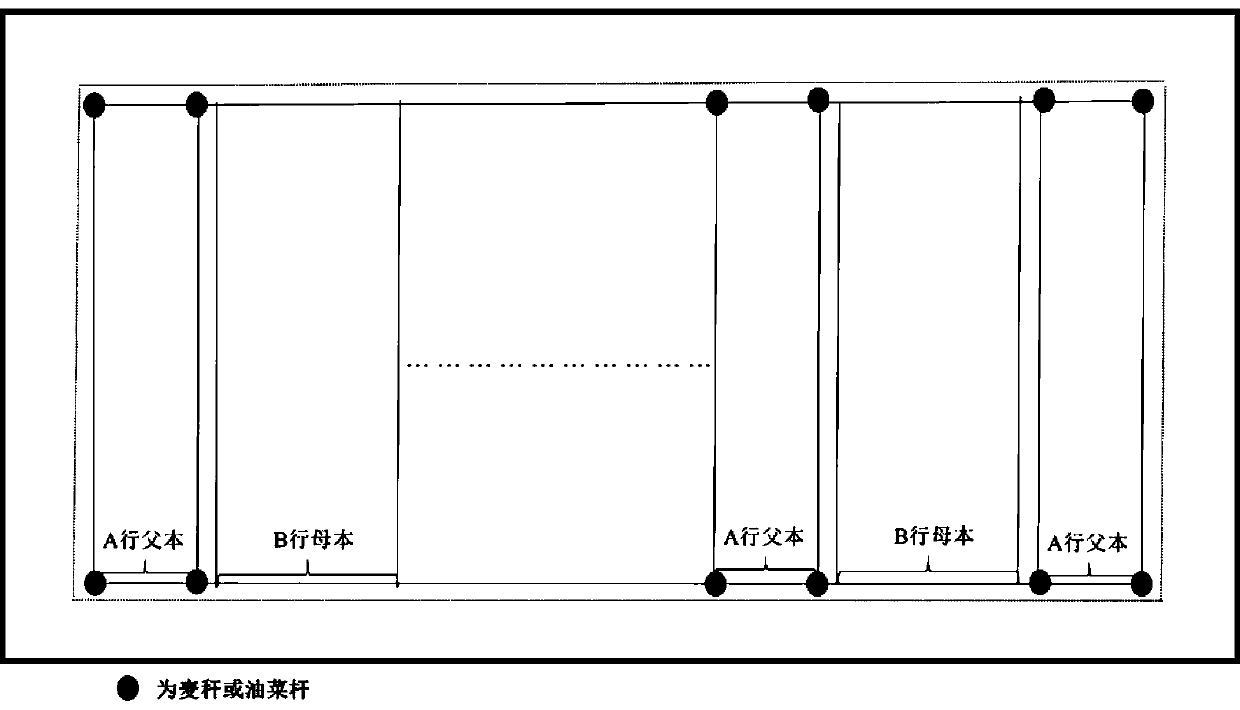

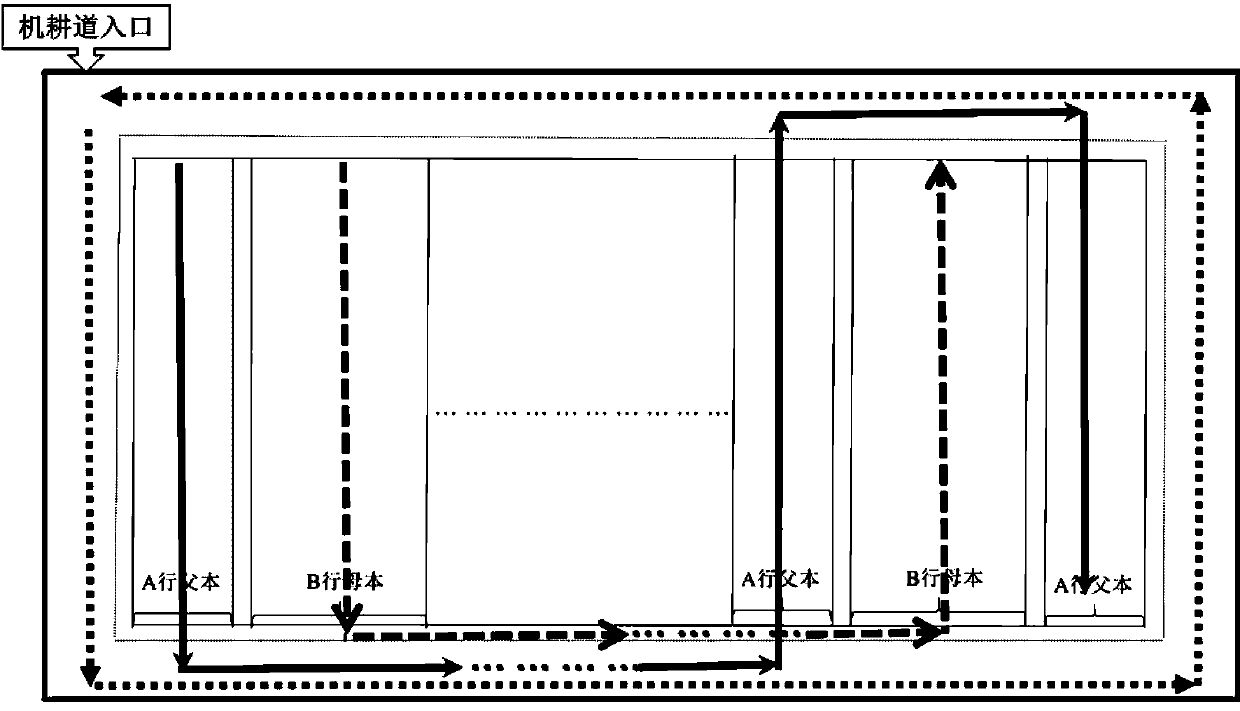

[0034] 1. According to the characteristics of the grain combine harvester with a cutting width of 1.5-2.0 meters commonly used in production, an enclosure with a width of r is reserved around the seed production field to plant the female parent, and r is less than or equal to the cutting width of the grain combine harvester Width, row spacing of the female parents is 0.3 meters, the number of planting rows is the maximum value determined according to the cutting width of the grain combine harvester used and the row spacing of the female parents, and the distance between the outer female parent box and the inner planting box is d', d'=0.47 meters . Wherein (r+d') is greater than the cutting width of the combine harvester, and the female planting box width is less than or equal to the cutting width of the combine harvester. In this way, there is a slightly larger interval between the inner and outer periphery than the row spacing, which can clearly distinguish the inner and oute...

Embodiment 2

[0048] 1. According to the characteristics of the grain combine harvester with a cutting width of 1.5-2.0 meters commonly used in production, an enclosure with a width of r is reserved around the seed production field to plant the female parent, and r is less than or equal to the cutting width of the grain combine harvester Width, row spacing of the female parents is 0.3 meters, the number of planting rows is the maximum value determined according to the cutting width of the grain combine harvester used and the row spacing of the female parents, and the distance between the outer female parent box and the inner planting box is d', d'=0.5 meters . Wherein (r+d') is greater than the cutting width of the combine harvester, and the female planting box width is less than or equal to the cutting width of the combine harvester. In this way, there is a slightly larger interval between the inner and outer periphery than the row spacing, which can clearly distinguish the inner and outer...

Embodiment 3

[0059] 1. According to the characteristics of the grain combine harvester with a cutting width of 1.5-2.0 meters commonly used in production, an enclosure with a width of r is reserved around the seed production field to plant the female parent, and r is less than or equal to the cutting width of the grain combine harvester Width, row spacing of the female parents is 0.3 meters, the number of planting rows is the maximum value determined according to the cutting width of the grain combine harvester used and the row spacing of the female parents, and the distance between the outer female parent box and the inner planting box is d', d'=0.45 meters . Wherein (r+d') is greater than the cutting width of the combine harvester, and the female planting box width is less than or equal to the cutting width of the combine harvester. In this way, there is a slightly larger interval between the inner and outer periphery than the row spacing, which can clearly distinguish the inner and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com