Automatic tobacco leaf sorting system

An automatic sorting system and tobacco leaf technology, applied in sorting, tobacco, tobacco preparation, etc., can solve the problems of increasing manpower, material resources, and financial resources, and achieve the effect of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

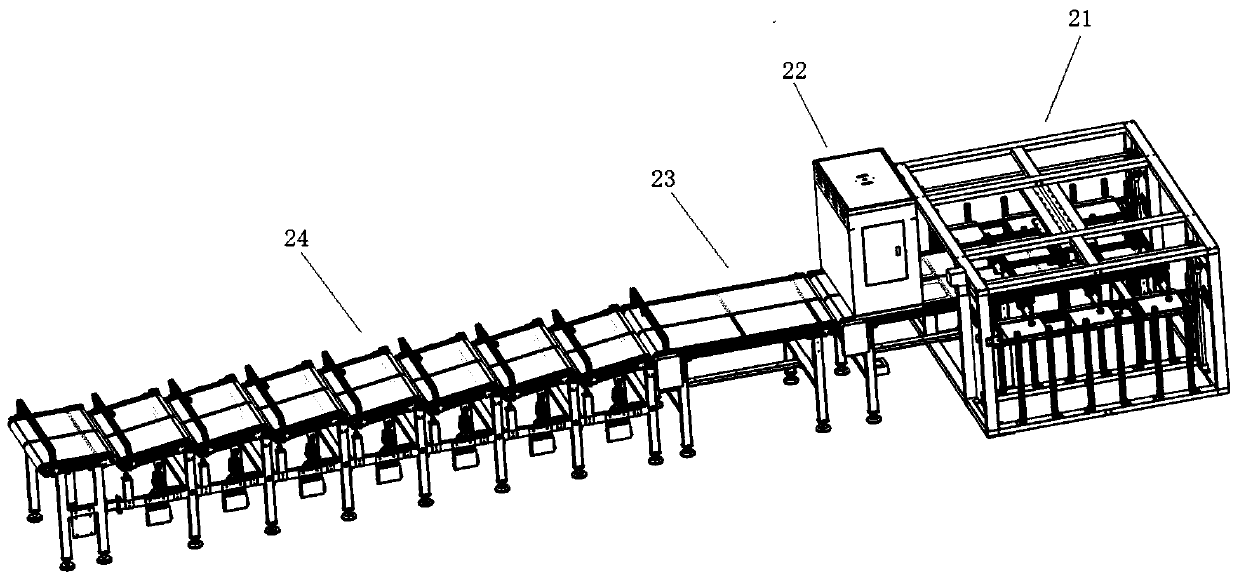

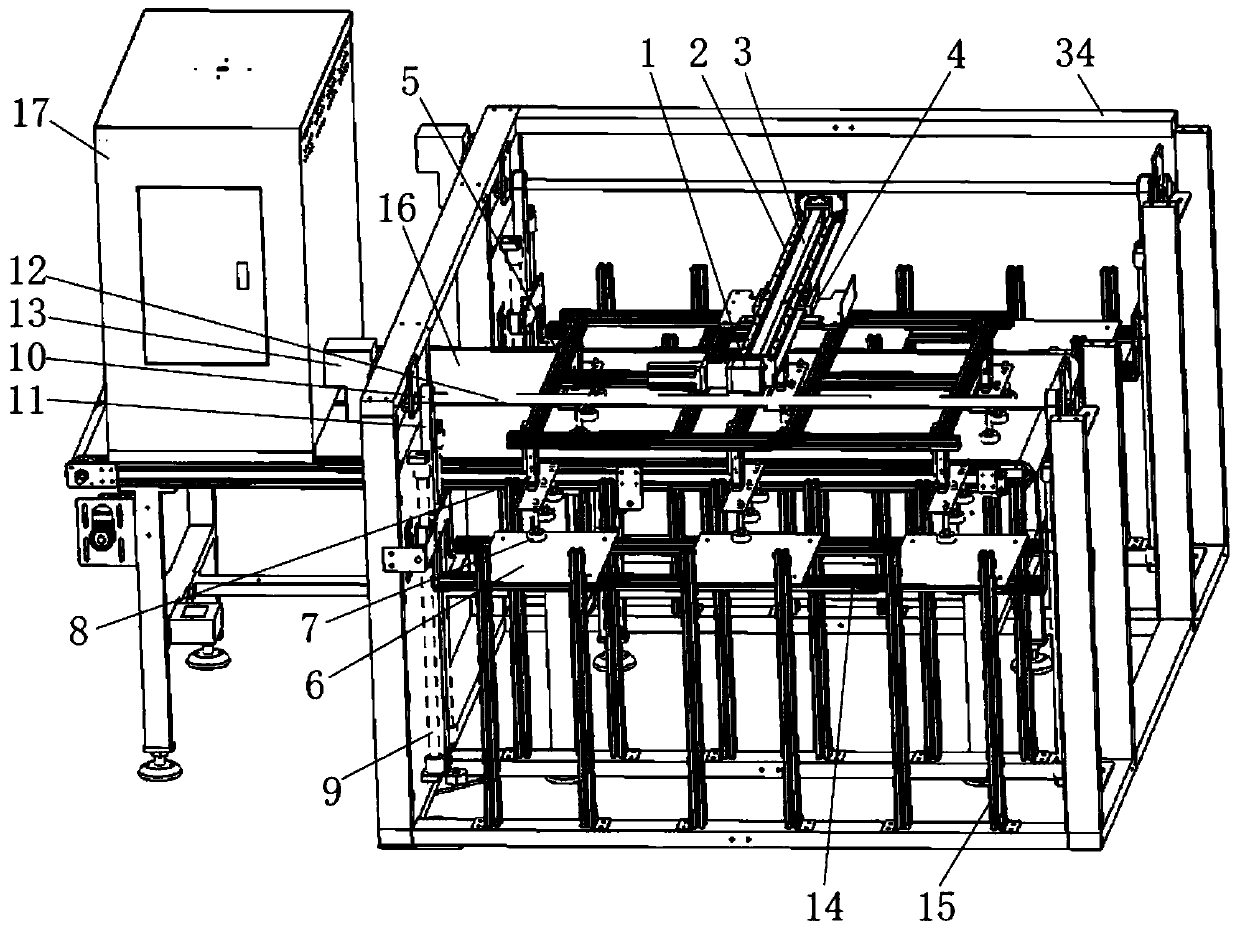

[0022] Such as figure 1 As shown, the tobacco leaf automatic sorting system includes a tobacco leaf feeding device 21 , a tobacco leaf feature recognition device 22 and a sorting device 24 arranged in sequence.

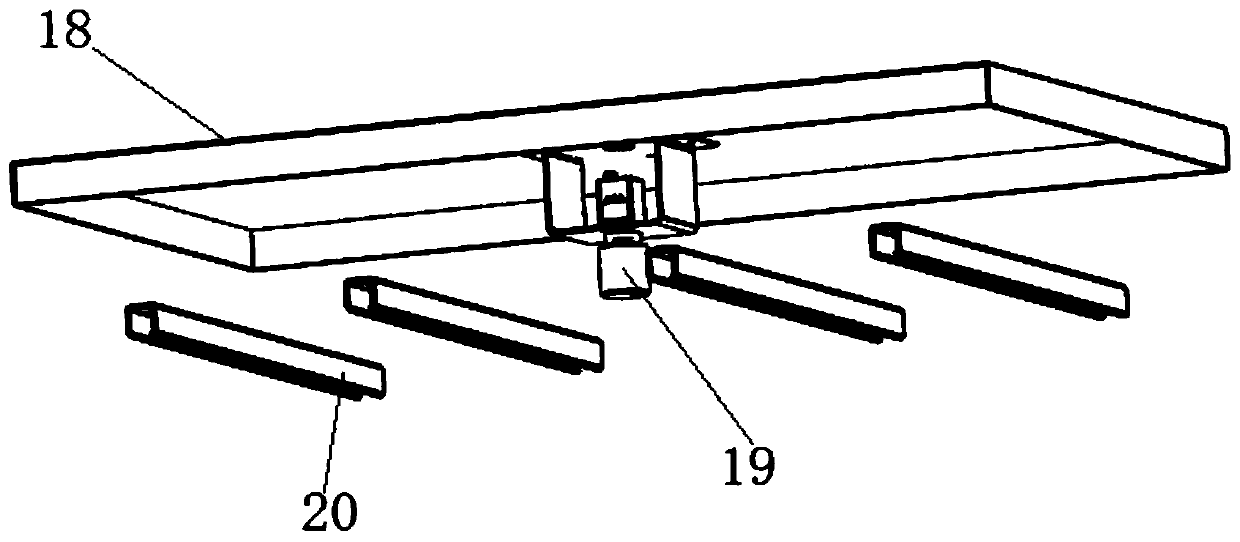

[0023] The tobacco leaf feeding device 21 is used for placing the tobacco leaves at a designated position. Such as figure 2 As shown, the tobacco leaf feeding device 21 includes a first power unit and a mounting frame 5, and the mounting frame 5 is installed on the support 34 by the first power device, and the first power device drives the mounting frame 5 to move on the support 34 ( That is, it moves between the position of absorbing tobacco leaves and the position of placing tobacco leaves). Described first power unit comprises guide rail 2 and belt 3, and described guide rail 2 is provided with slide block 4, and described slide block 4 moves on guide rail 2, and described guide rail 2 is connected with mounting frame 5; Described belt 3 installs On the belt dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com