Cutting device for automobile transmission shaft machining

A cutting device and transmission shaft technology, which is applied in the automotive field, can solve problems such as low work efficiency and lack of fixed-length cutting functions, and achieve the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

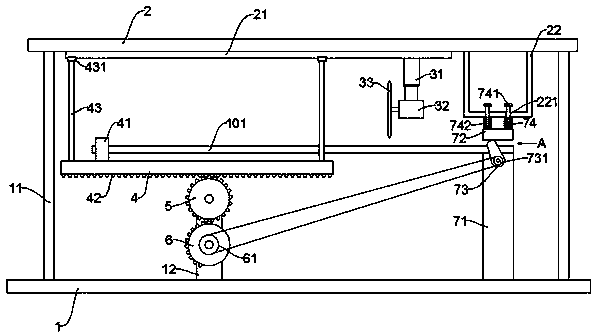

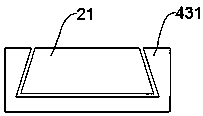

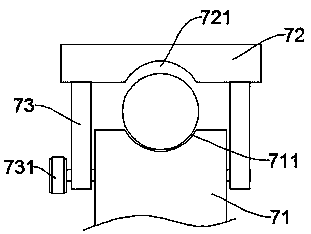

[0023] see Figure 1~3 , in an embodiment of the present invention, a cutting device for automobile transmission shaft processing, including a base 1, a placement seat 4 and a cutting assembly; the top of the base 1 is symmetrically fixed with a support frame 11 on both sides, and the support frame 11 on both sides The top of the top is connected with a top plate 2; the cutting assembly is installed on the bottom of the top plate 2; the placement seat 4 is arranged below the top plate 2 at intervals, and the four corners of the top of the placement seat 4 are fixed with connecting rods 43, and the connecting rods 43 The end is equipped with a guide card seat 431; the bottom of the top plate 2 is equipped with a guide rail 21 that matches the guide card seat 431, and the guide card seat 431 is slidingly clamped on the guide rail 21, so that the placement seat 4 can be placed on the top plate 2 Move, the top of the placement seat 4 is equipped with a fixed clamp 41 for fixing on...

Embodiment 2

[0031] see Figure 4 The difference between the embodiment of the present invention and embodiment 1 is that the top of the base 1 is provided with a debris collection frame 8 at the position below the blade 33, and the top of the base 1 is provided with a blank Material collecting frame 9, thereby can carry out debris and the blank material collection after cutting conveniently, be convenient to carry out follow-up processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com