Front loading assisting device of punching machine

A technology of auxiliary device and punching machine, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of increasing the burden on the enterprise, low degree of automation, and increased labor intensity of the staff, so as to improve the service life and use safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

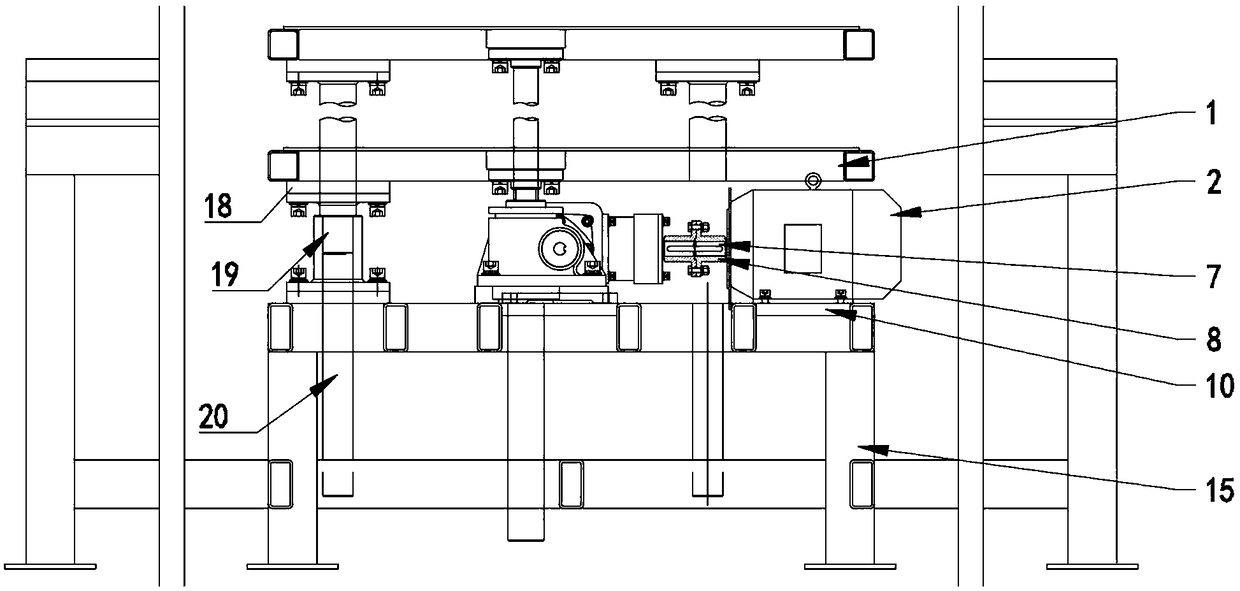

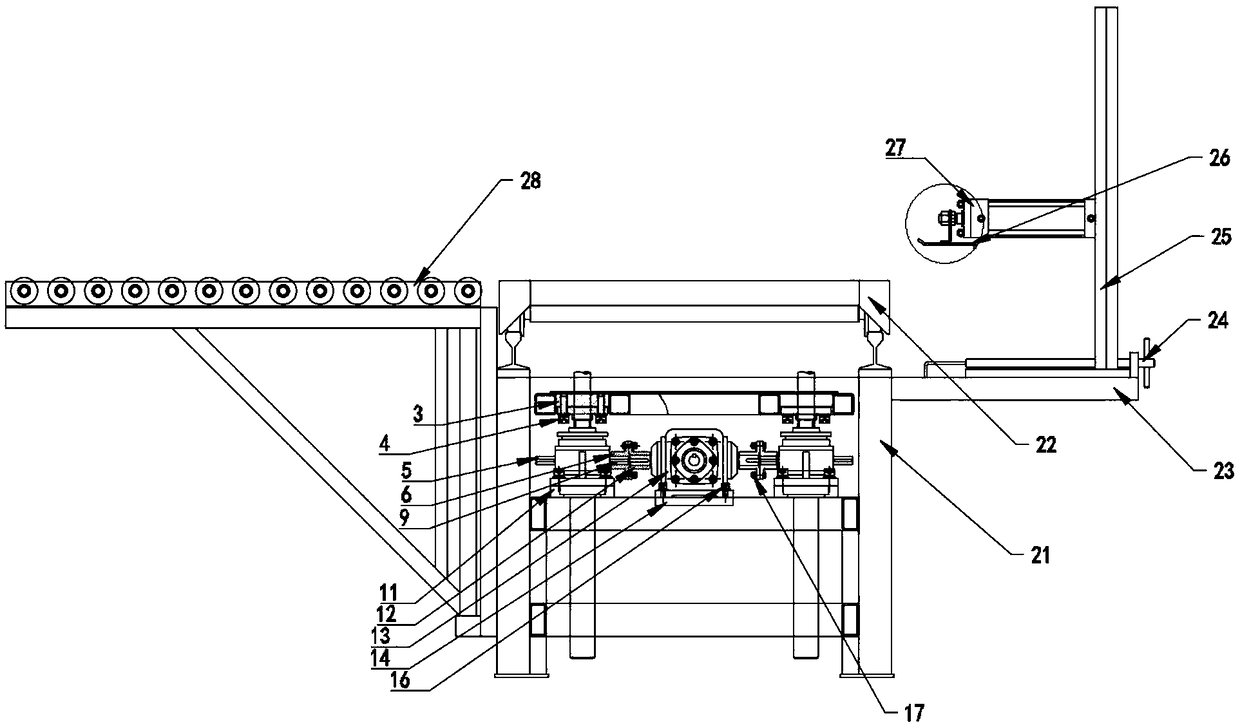

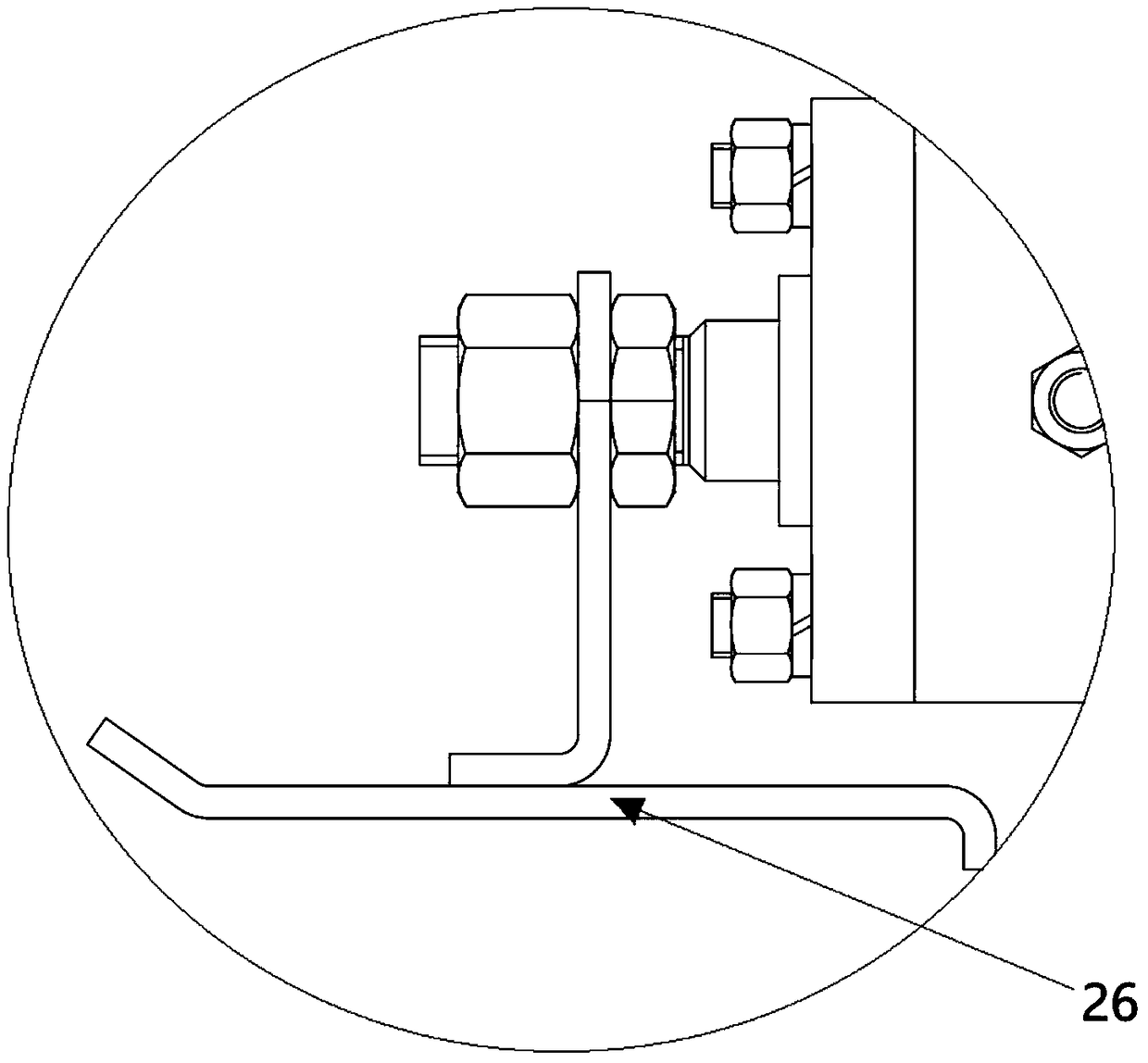

[0026] as attached figure 1 To attach image 3 Shown:

[0027] The present invention provides a feeding auxiliary device in front of a punching machine, which includes: a table assembly 1, a motor 2, an elevator end fixing plate 3, an M14 bolt 4, a SWL worm screw elevator 5, an elevator coupling 6, a B8 key 7, Motor coupling 8, B6 key 9, motor fixing plate 10, lift base fixing plate 11, steering box coupling 12, T-shaped spiral bevel gear steering box 13, steering box fixing plate 14, base assembly 15, M12 hexagon Head bolt 16, M8 hex head bolt and nut 17, guide fixing seat 18, guide sleeve 19, guide post 20, skeleton assembly 21, moving trolley 22, support seat assembly 23, push arm assembly 24, cylinder adjustment assembly 25, push plate assembly 26, light cylinder 27 and conveying roller assembly 28; the bottom wall of the table assembly 1 is provided with a guiding and fixing seat 18; the top side of the base assembly 15 is also provided with guiding and fixing Seat 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com