A Lofting Fabrication Method of Side Push Grille

A manufacturing method and grid technology, which can be used in ship building, ship design, ships, etc., and can solve the problems of not being able to stake out and make side thrust grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

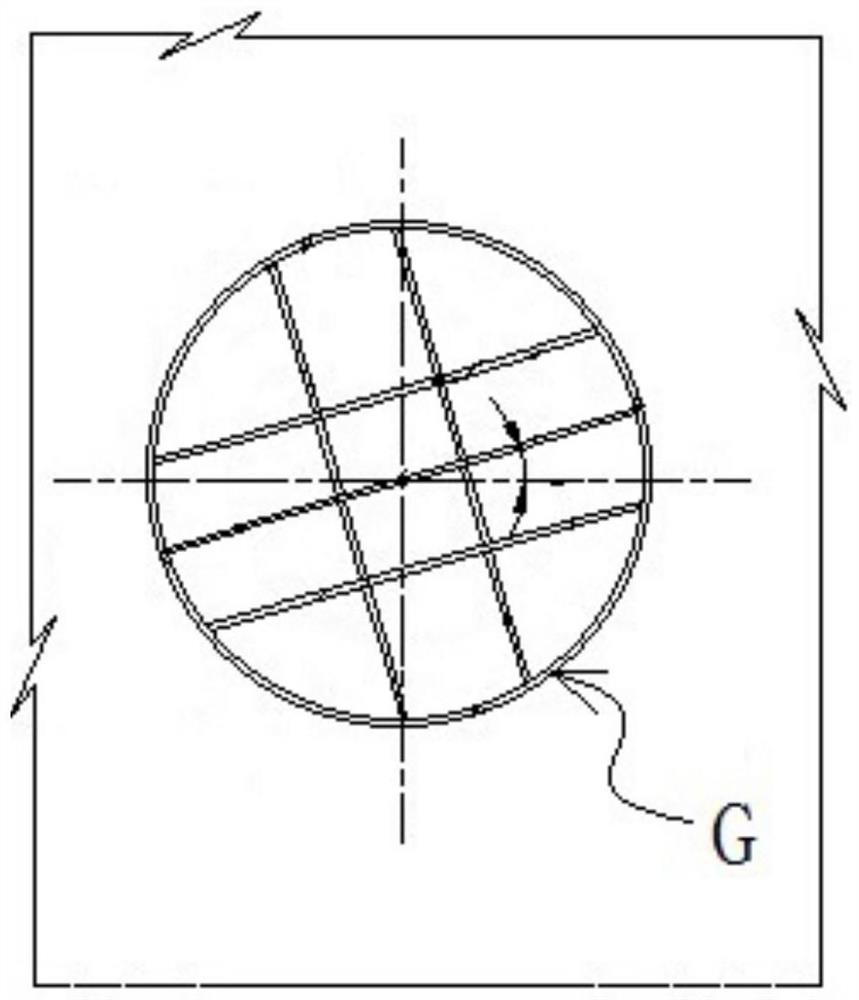

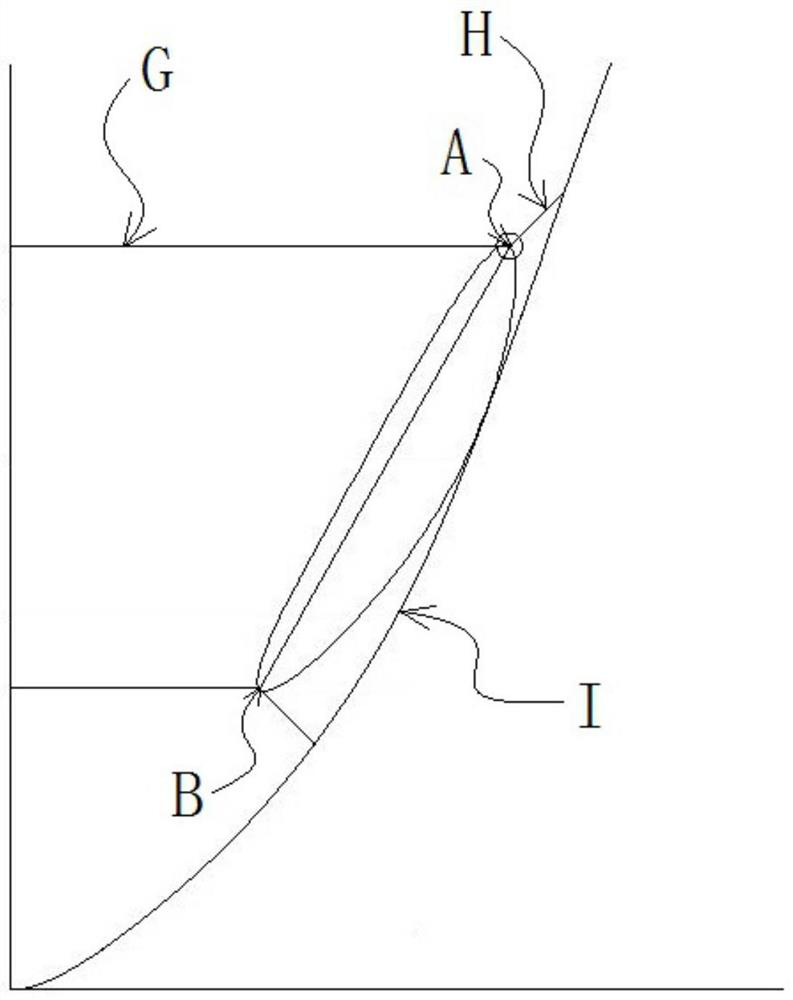

[0034] Specific embodiment 1 of the lofting manufacturing method of the lateral thrust grid of the present invention, as figure 1 , figure 2 As shown, the side thruster is installed in the cylinder G that runs through the hull transversely. Between the two ports of the cylinder G and the outer plate I of the hull, there is a flared deflector H, through which the cylinder G The port of G is transitionally connected with the outer plate I of the hull, and the lateral thrust grille is installed at the two ports of the cylinder G along the inclination angle compatible with the deflector H, and the external garbage and foreign matter are effectively isolated through the later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com