Polygonal intake tower for specified-height water intaking at reservoir water tunnel entrance

A technology for water delivery tunnels and water inlet towers, which is applied to the configuration of drinking water installations, water supply pools, towers, etc., can solve problems such as complex structures, failure to reach the designated height of the reservoir, and large gate size, etc., to save engineering costs, Novel structural layout, beautiful and practical overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

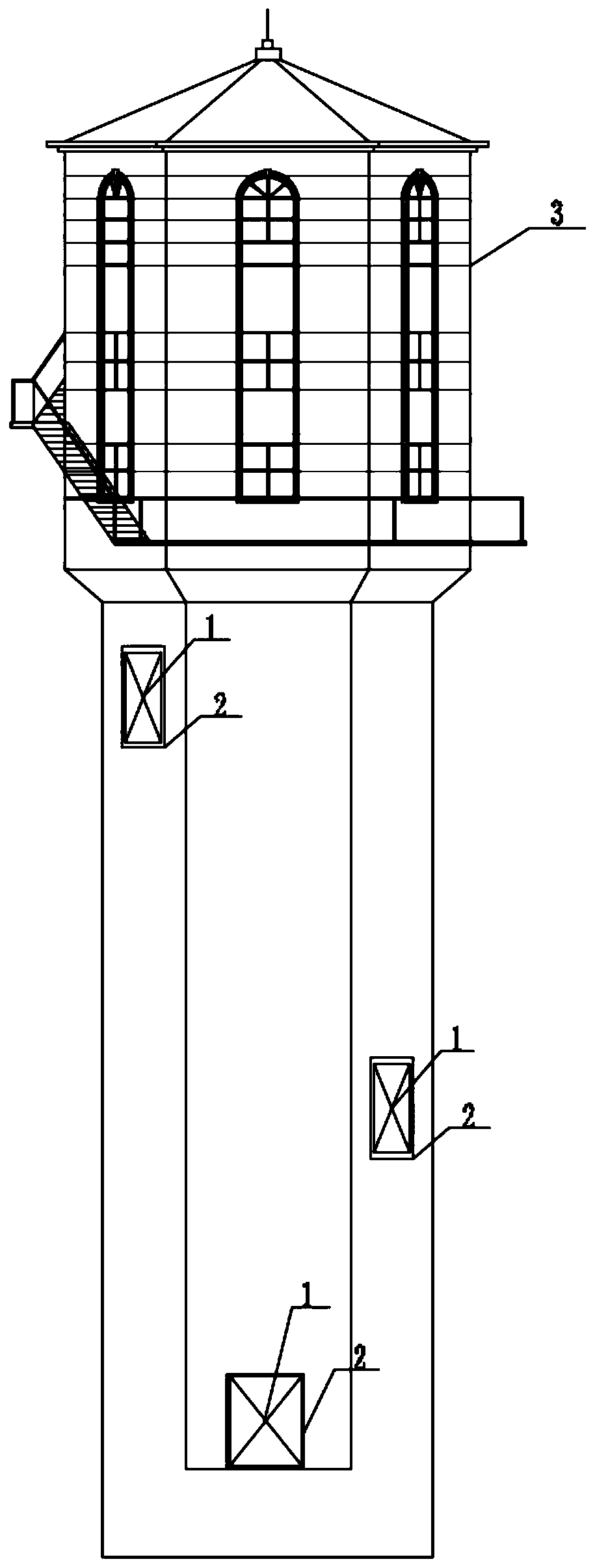

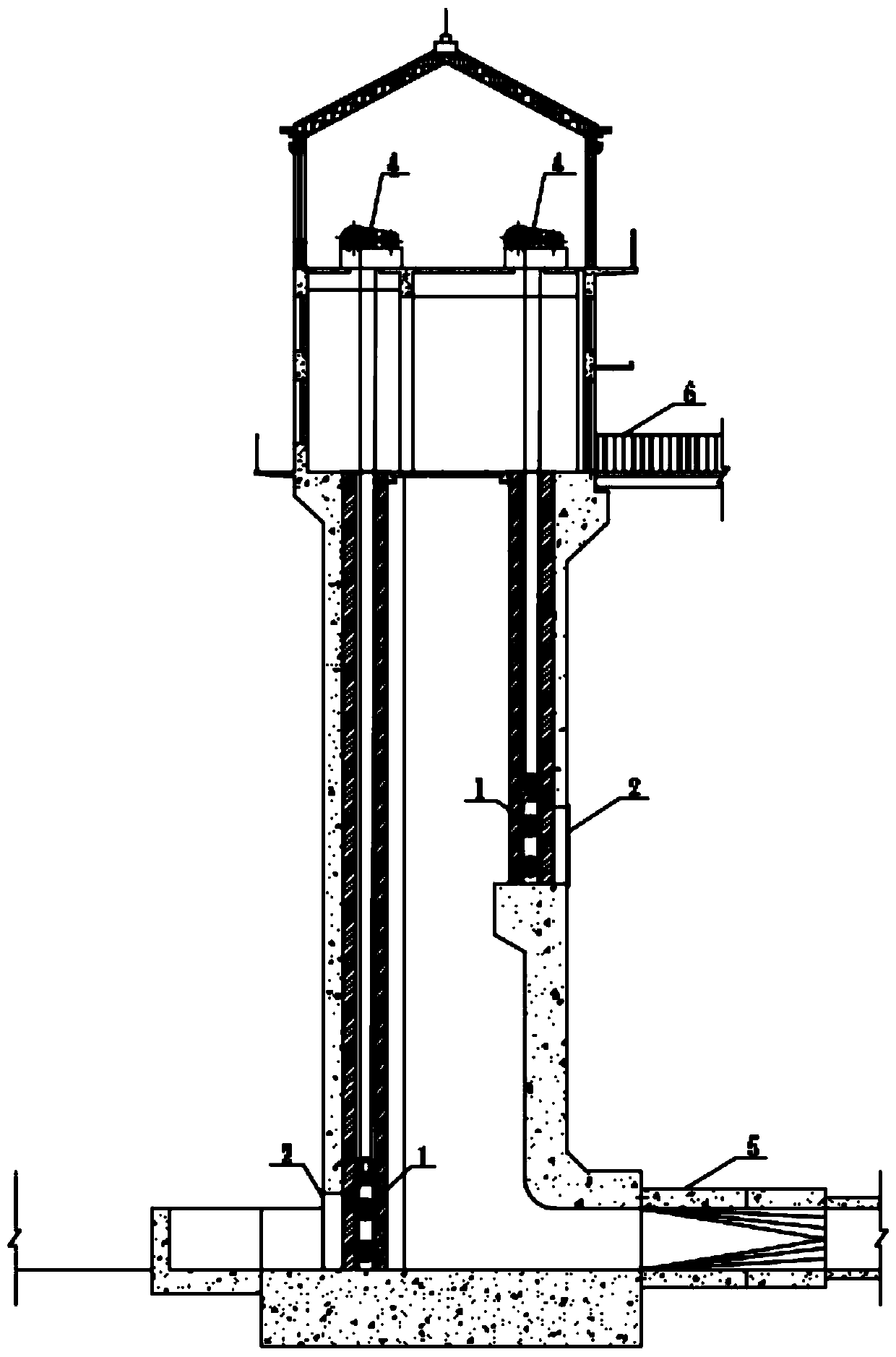

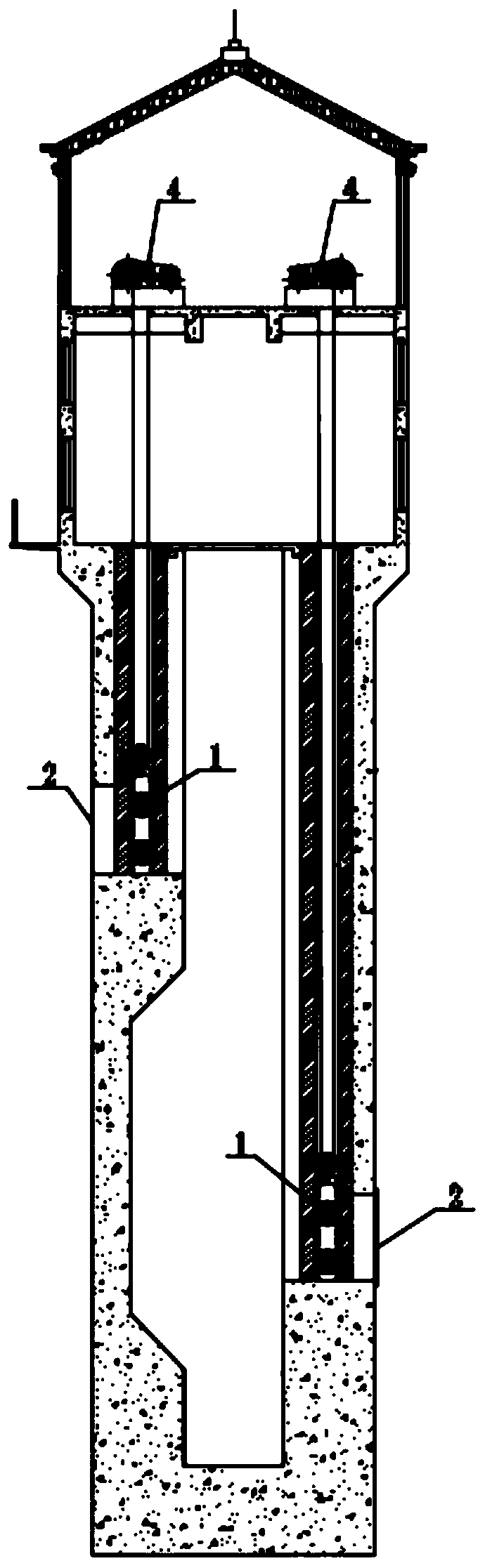

[0015] Such as Figure 1-4 As shown, the polygonal water inlet tower for water intake at a specified height at the entrance of the reservoir water tunnel of the present invention includes a plurality of flat gates 1, a fixed trash rack 2 fixed in front of the flat gates, and a hoist room at the top of the tower 3. A plurality of hoist hoists 4, a water delivery tunnel 5, and a traffic bridge 6. The cross section of the water inlet tower is a regular polygon, and a plurality of flat gates 1 are arranged circularly along the side wall of the regular polygon water inlet tower. At different elevations, the winch hoist 4 is arranged in the hoist room 3 on the top of the tower corresponding to the lifting of the flat gate 1, and the hoist 4 is used to pick and place the flat gate 1 to achieve the purpose of water intake at a specified height .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com