Novel L-shaped square steel formwork support, adjustable column hoop and construction method

A formwork support and steel formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, and on-site preparation of building components, which can solve the problem of reducing construction efficiency and increasing materials and labor. Cost, poor universality of formwork steel support, etc., to achieve the effect of improving work efficiency, solving poor universality and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

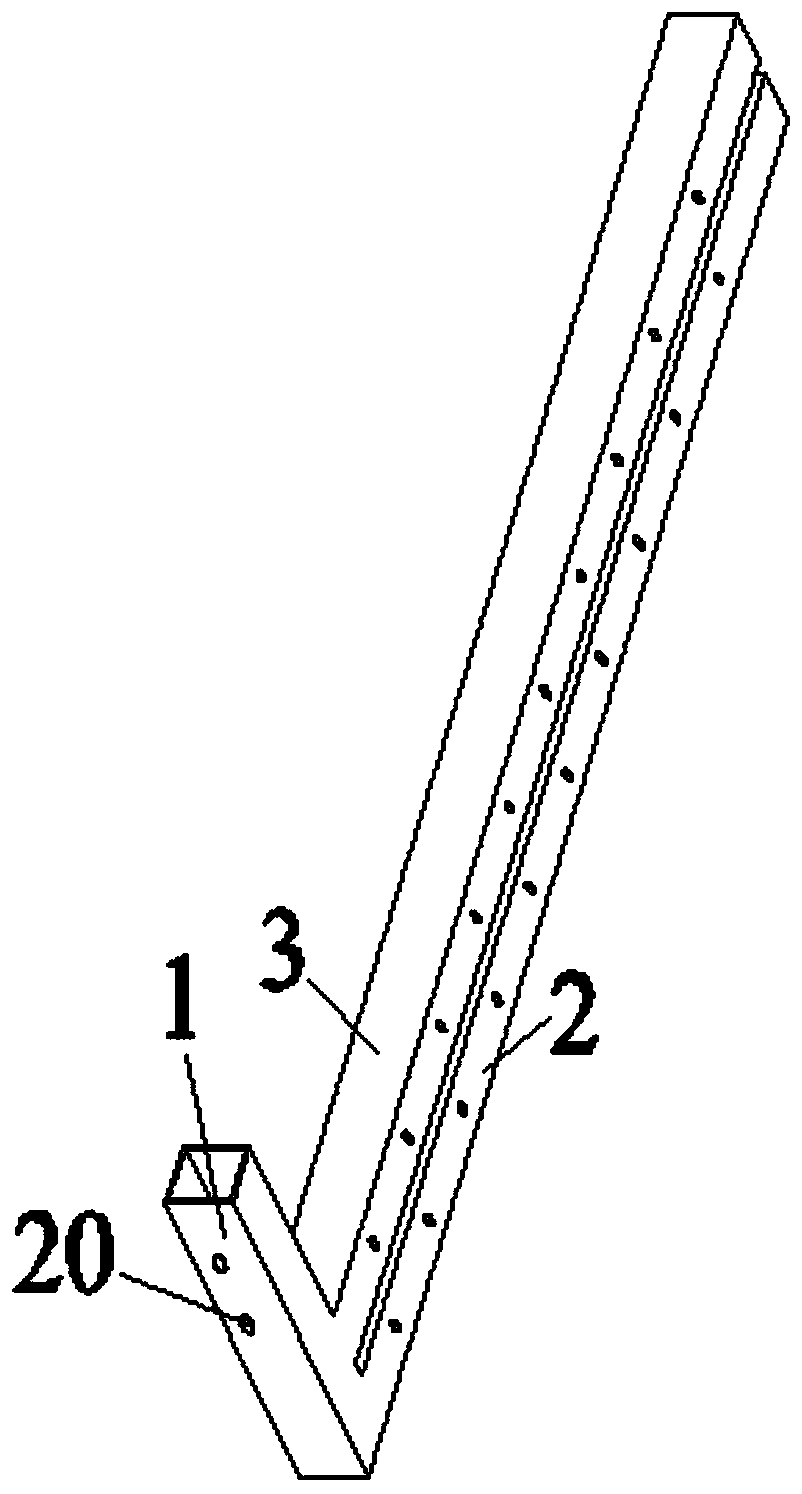

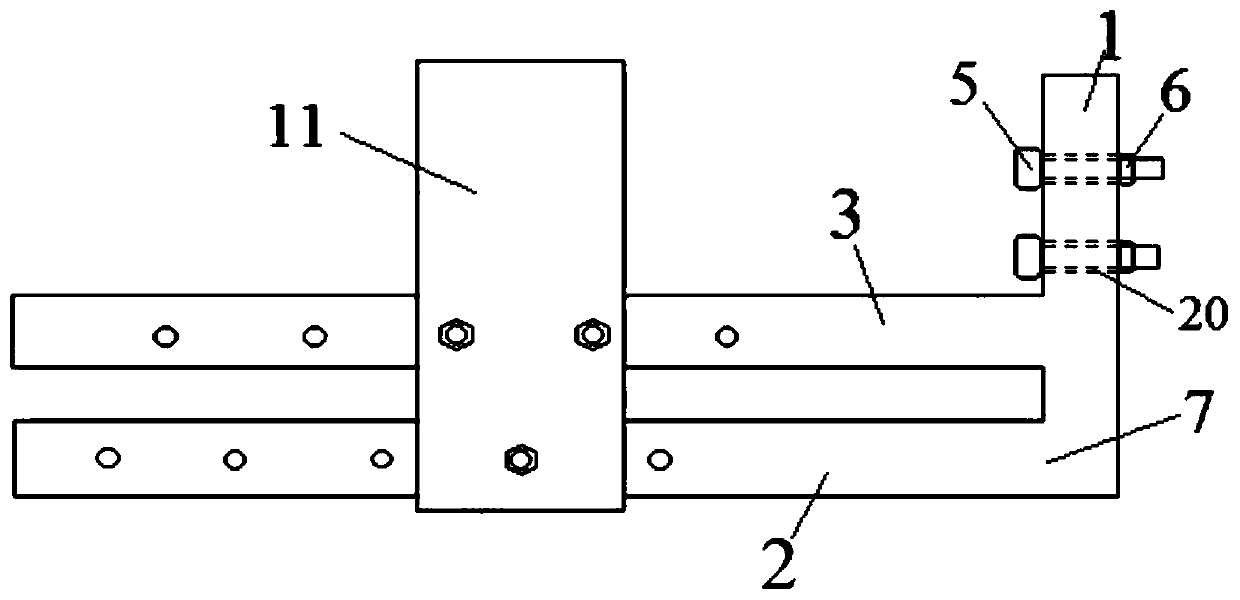

[0053] Such as figure 1 As shown, the three-dimensional structural diagram of the first formwork support 7, a novel L-shaped square steel formwork support used by a shear wall 19 and a structural column 17, includes a first square steel 1 and a second square steel 2 perpendicular to each other, so One end of the first square steel 1 is connected with one end of the second square steel 2 to form an L shape, and the new L-shaped square steel template support also includes a third-party steel parallel to the second square steel 2 3. One end of the third-party steel 3 is set on the first square steel 1, and the second square steel 2 and the third-party steel 3 are set on the same side of the first square steel 1;

[0054] Wherein, the distance between the second square steel 2 and the third-party steel 3 has a gap, the gap is used to fit the wall-through screw 4, the wall-through screw 4 is used to pass through the wall, and the wall-through For the specific setting position of s...

Embodiment 2

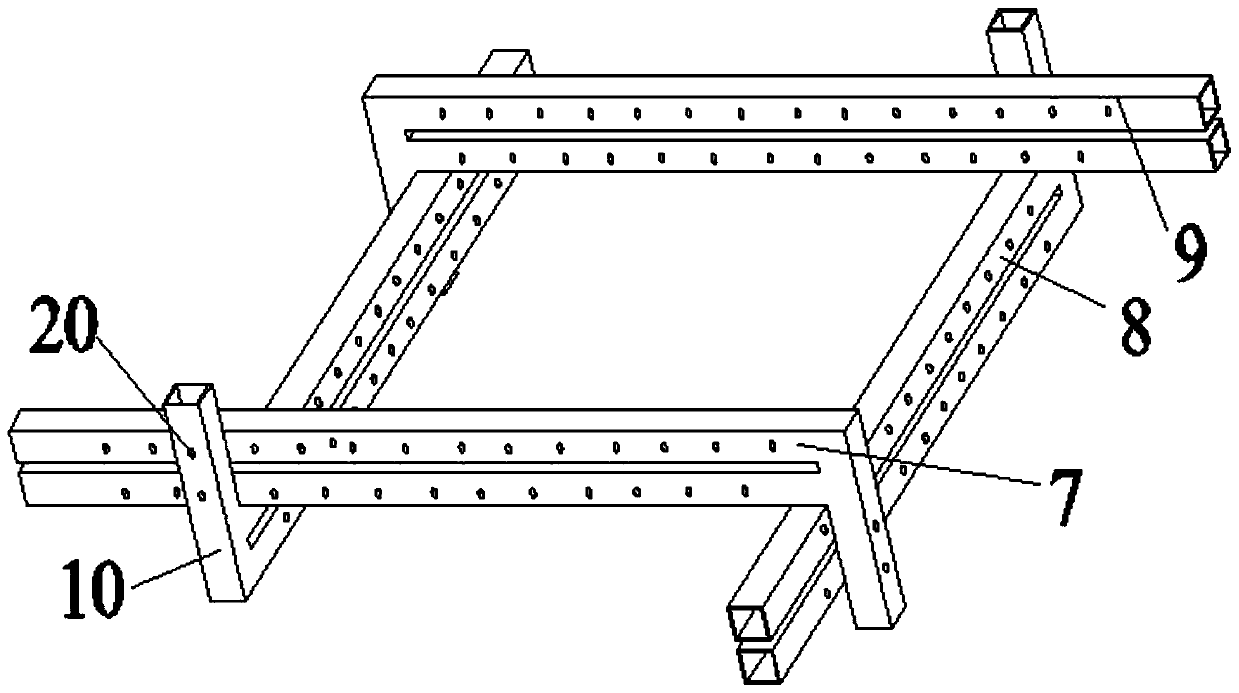

[0059] Such as image 3 As shown, the matching diagram of the first formwork support 7, the second formwork support 8, the third formwork support 9 and the fourth formwork support 10, the first formwork support 7, the second formwork support 8, the third formwork support 9 and the fourth formwork support The formwork supports 10 have the same structure, the four formwork supports are connected end to end, and the two adjacent formwork supports are perpendicular to each other, and cooperate with each other to form a square column hoop with an adjustable hollow part.

[0060] Such as Figure 4 as shown, Figure 4 It is a three-dimensional structural diagram of an adjustable column hoop, an adjustable column hoop, including four novel L-shaped square steel formwork supports used in the shear walls 19 and structural columns 17, that is, the first formwork support 7, the second formwork The support 8, the third formwork support 9 and the fourth formwork support 10, the four formw...

Embodiment 3

[0069] A construction method for an adjustable column hoop comprises the following steps:

[0070] Step 1, install the structural column 17 formwork according to the structural column 17 control line;

[0071] Step 2. Set the L-shaped square steel as a column hoop according to the formwork of the structural column 17, that is, set the first formwork support 7, the second formwork support 8, the third formwork support 9 and the fourth formwork support 10 to form an adjustable column hoop;

[0072] Step 3: According to the size of the structural column 17, fix the first lock 11, the second lock 12, the third lock 13 and the fourth lock 14 on the corresponding first formwork support 7, second formwork support 8, and third formwork support 9 And the position on the fourth template support 10;

[0073] Step 4, fine-tuning the positions of the first formwork support 7, the second formwork support 8, the third formwork support 9 and the fourth formwork on the structural column 17; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com