Rotating wheel design method of ultrahigh water head section mixed flow water turbine with guide blades

A technology of guide vane and design method, which is applied to mechanical equipment, reaction engines, hydroelectric power generation, etc. It can solve the technical difficulties of high-head mixers, etc., and achieve improved hydraulic stability, reduced hydraulic vibration, and improved power generation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

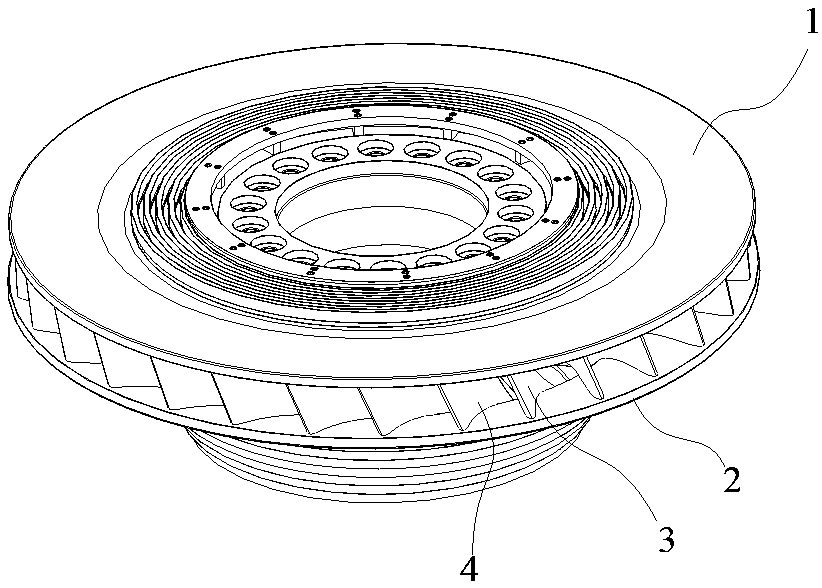

[0021] Such as figure 1 In the illustrated embodiment, a method for designing a runner of a Francis turbine with guide vanes at an ultra-high head section includes the following steps:

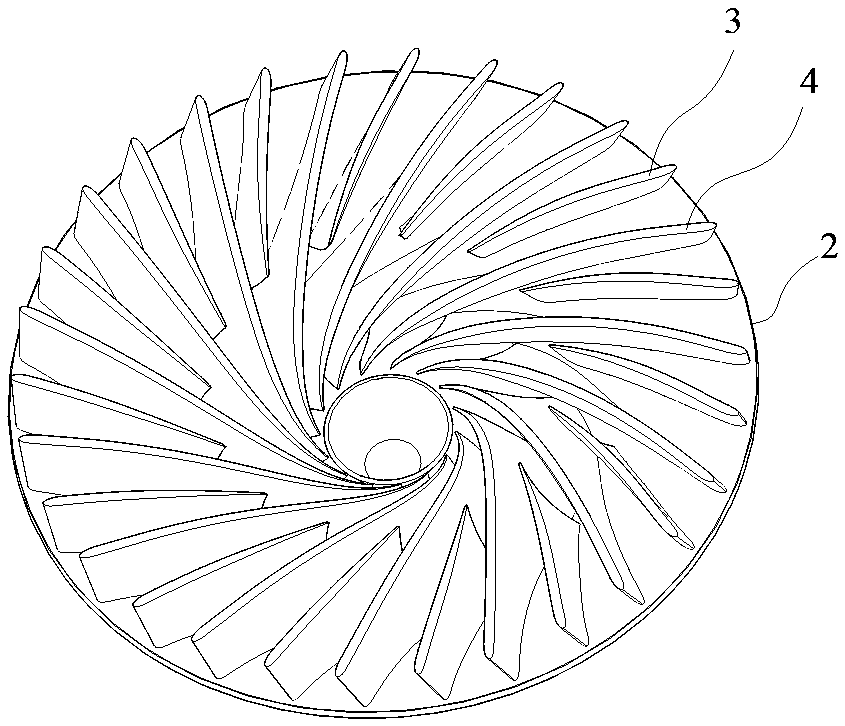

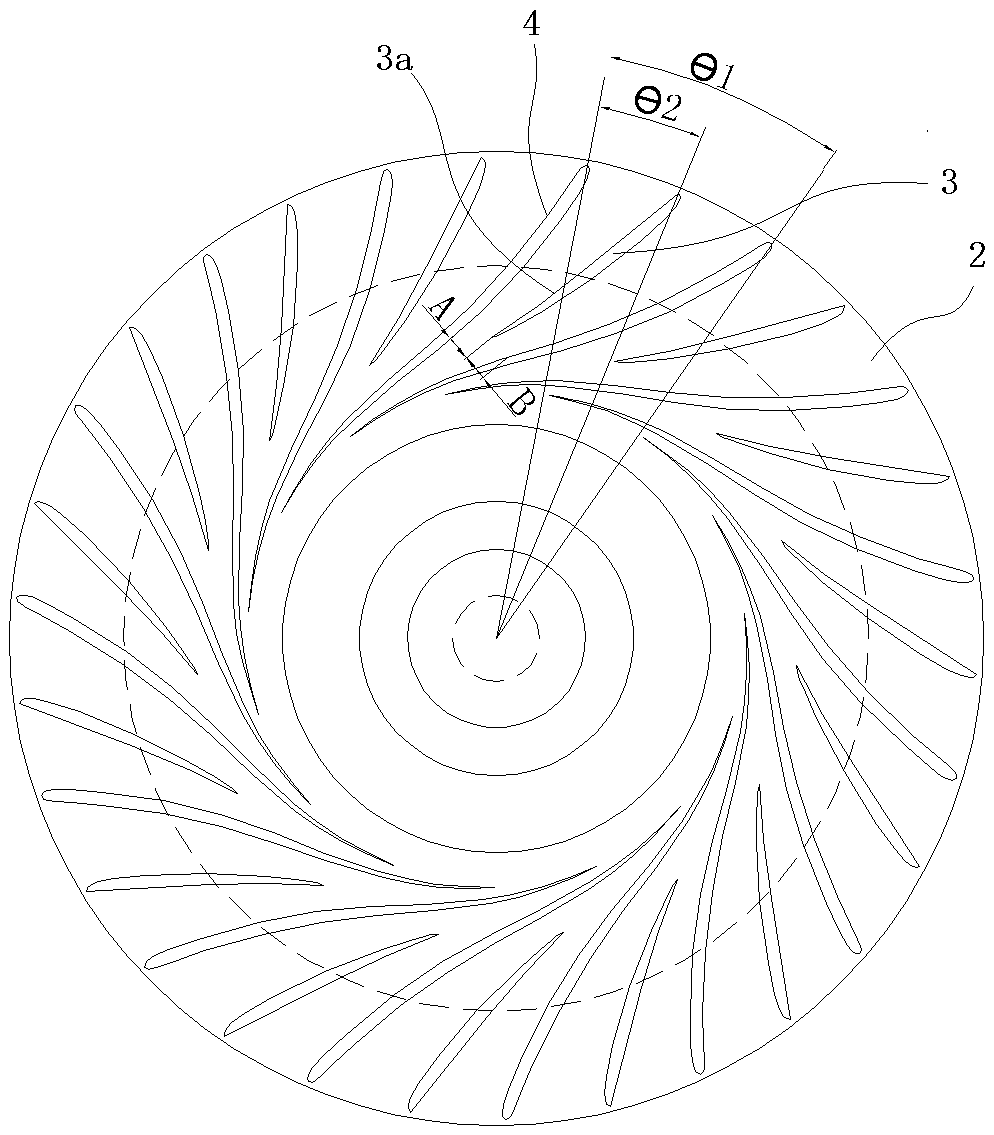

[0022] a. Guide vanes and runner blades are arranged on the runner, and the guide vanes and runner blades are alternately arranged at intervals, and the length of the guide vanes is shorter than that of the runner blades; figure 1 As shown, the runner includes an upper crown 1 and a lower ring 2, and runner blades 4 and guide vanes 3 are arranged between the upper crown 1 and the lower ring 2, and the runner blades 4 and guide vanes 3 are arranged along the rotation axis of the runner The centers are evenly arranged, and the runner blades 4 and guide vanes 3 are alternately arranged. combine figure 2 , image 3 As shown, the runner blade 4 is longer, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com